Intelligent dredging vehicle for deep inspection well

A technology for dredging vehicles and deep inspection wells, which is applied to waterway systems, earth movers/excavators, water supply devices, etc., and can solve the problems of ground pollution, high labor intensity, and lack of oxygen at the entrance of inspection wells, so as to ensure life safety, High degree of intelligence, easy to operate and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

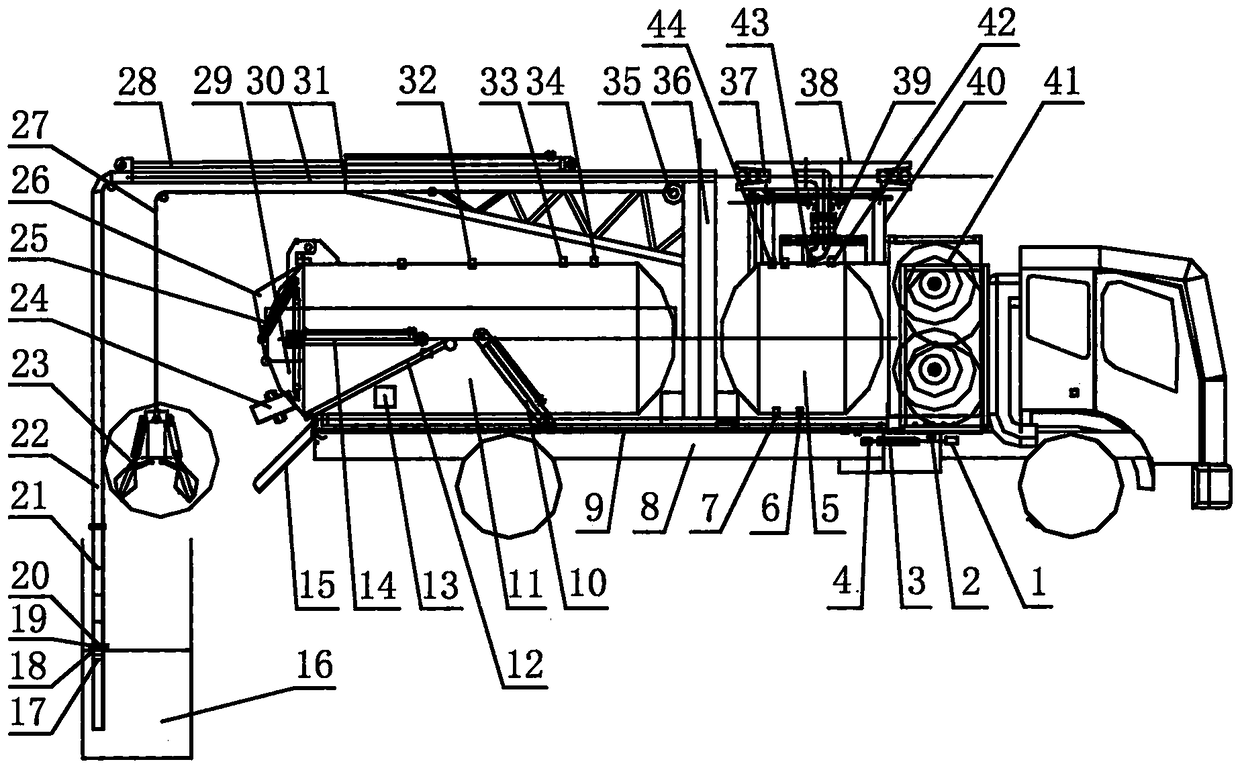

[0018] Below in conjunction with accompanying drawing, the deep inspection shaft intelligent dredging of the present invention is described in detail.

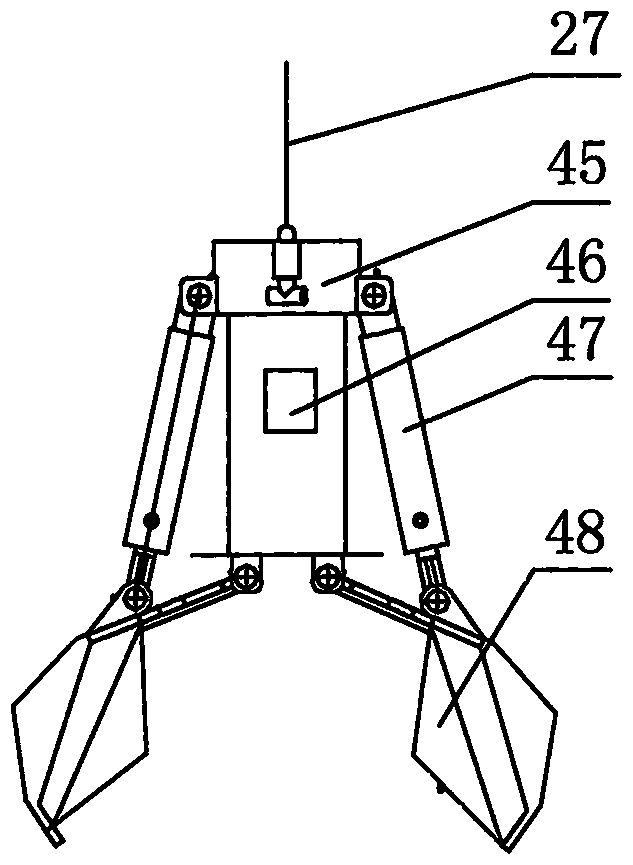

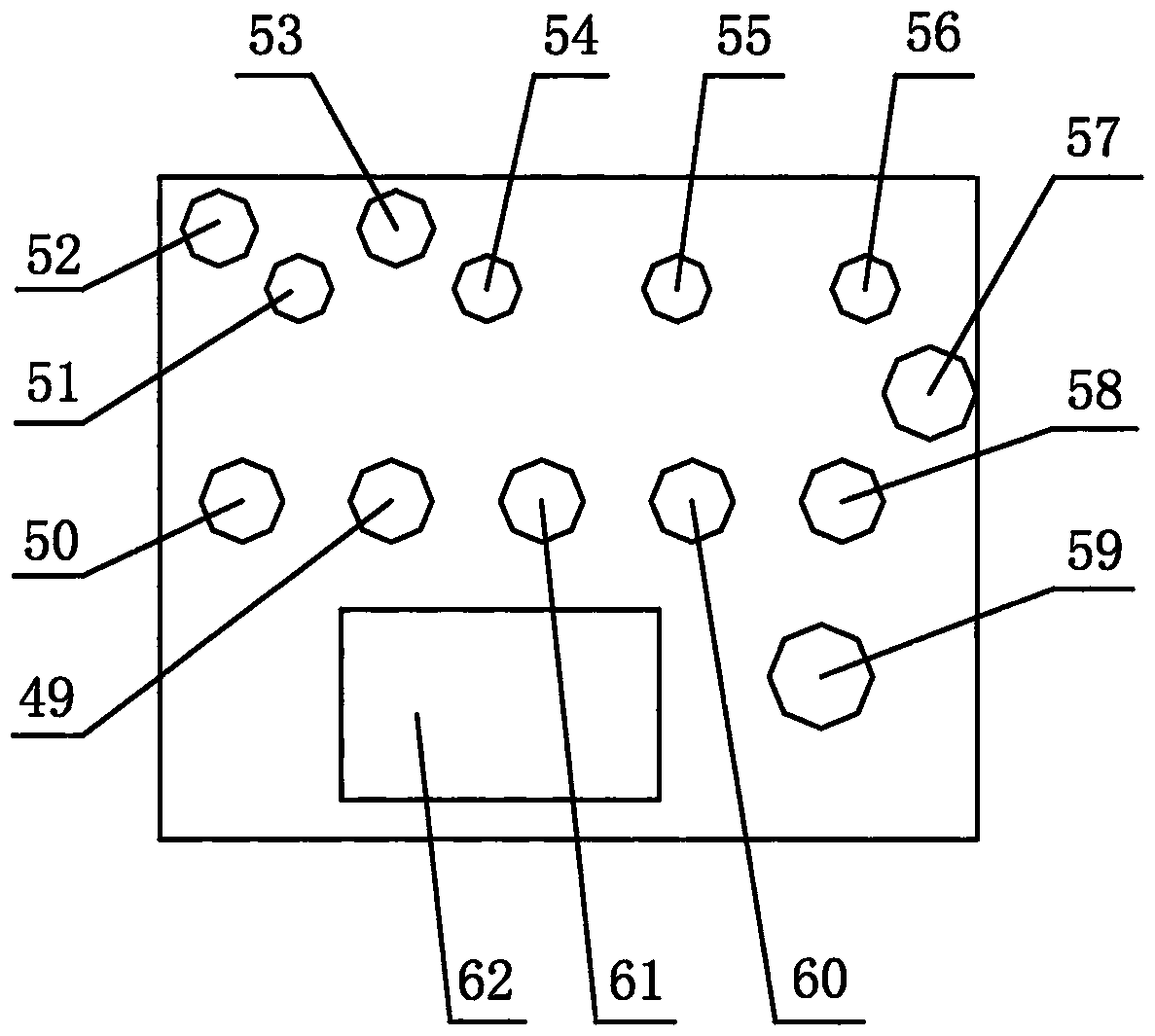

[0019] see Figure 1 to Figure 3, the intelligent dredging of the deep inspection well of the present invention comprises a chassis 8, a subframe 9 is set on the chassis 8, a gas cabinet 41 and a clean water tank 5 are arranged at the front of the subframe 9, and the top of the clean water tank 5 is provided with a ball valve. The water inlet 42 and the air inlet 43 of switch, the bottom is provided with water outlet 6, and the rear portion of auxiliary frame 9 is established dirt suction tank 11. The tail of the sewage suction tank 11 is connected with the subframe 9 through a rotating shaft, and a sewage suction tank lifting cylinder 10 connected with the sewage suction tank 11 is arranged on the subframe 9, and the sewage suction tank can be rotated around the rotating shaft through the sewage suction tank lifting cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com