Construction Method of Inorganic Dry Powder Striped Exterior Wall Decorative Mortar Coating System

An inorganic dry powder, exterior wall decoration technology, applied in chemical instruments and methods, hydraulic material layered products, covering/lining, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

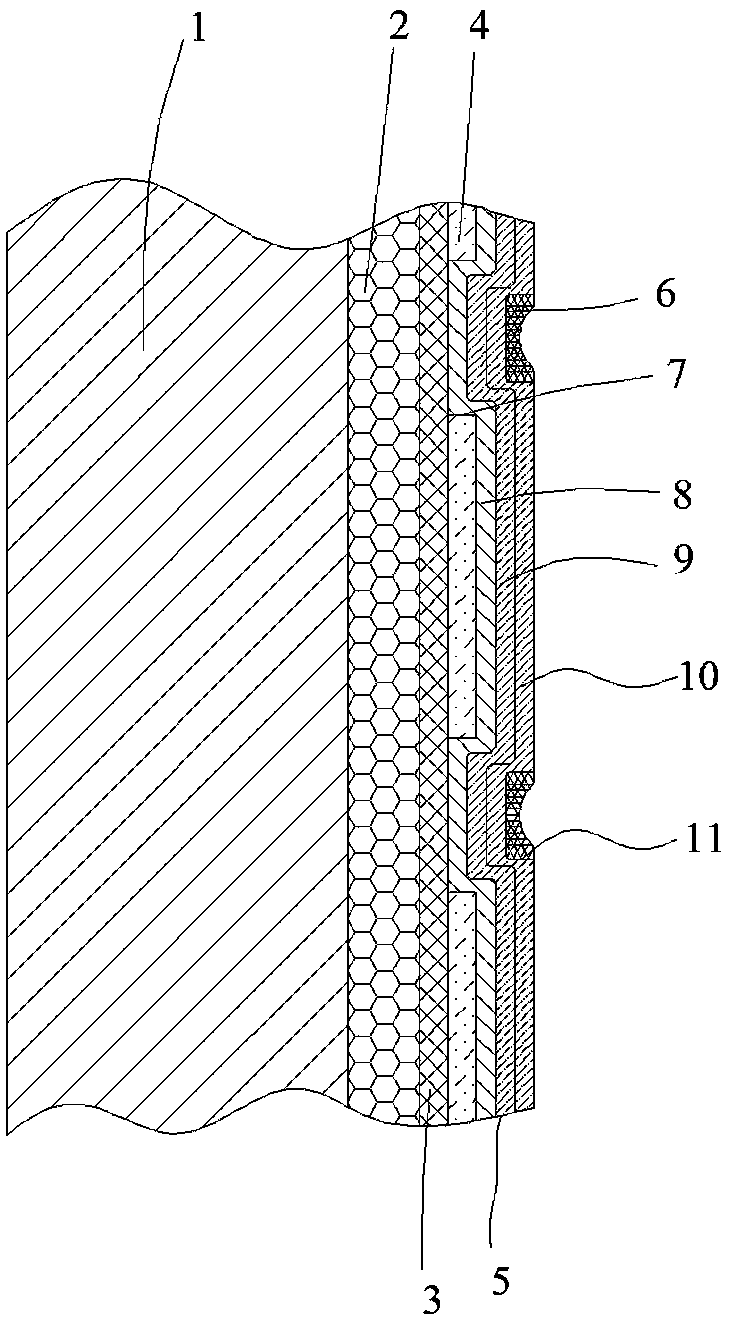

[0022] Embodiment 1: as figure 1 As shown, the construction method of the inorganic dry powder striped exterior wall decorative mortar coating system includes the following steps:

[0023] Step 1, base treatment: the base includes brick wall 1, inorganic thermal insulation mortar 2, plastering anti-cracking layer 3, the brick wall 1 is kept clean and tidy, the inorganic thermal insulation mortar 2 is arranged on the outer surface of the brick wall 1, and the The plastering anti-cracking layer 3 is laid on the outer surface of the inorganic thermal insulation mortar 2, and the plastering anti-cracking layer 3 is a smooth layer on the outer surface made of cement mortar;

[0024] Step 2, snapping the grid sutures: according to the needs, pop the grid sutures on the outer surface of the anti-crack layer 3 of the plastering surface, and after the grid sutures are completed, the Paste masking paper on the position, and the masking paper coincides with the grid stitching;

[0025]...

Embodiment 2

[0036] Embodiment 2: as figure 1 As shown, the construction method of the inorganic dry powder striped exterior wall decorative mortar coating system includes the following steps:

[0037] Step 1, base treatment: the base includes concrete wall 1, rock wool 2, plastering anti-cracking layer 3, the brick wall 1 is kept clean and tidy, the rock wool 2 is arranged on the outer surface of the brick wall 1, and the plastering surface The anti-cracking layer 3 is laid on the outer surface of the rock wool 2, and the plastering anti-cracking layer 3 is a flat layer on the outer surface made of cement mortar;

[0038] Step 2, snapping the grid sutures: according to the needs, pop the grid sutures on the outer surface of the anti-crack layer 3 of the plastering surface, and after the grid sutures are completed, the Paste masking paper on the position, and the masking paper coincides with the grid stitching;

[0039] The following are the requirements for the base layer and the grid s...

Embodiment 3

[0050] Embodiment 3: as figure 1 As shown, the construction method of the inorganic dry powder striped exterior wall decorative mortar coating system includes the following steps:

[0051] Step 1, base treatment: the base includes brick wall 1, polystyrene extruded board 2, plastering anti-cracking layer 3, the brick wall 1 is kept clean and tidy, and the polystyrene extruded board 2 is arranged on the top of the brick wall 1 On the outer surface, the plastering anti-cracking layer 3 is laid on the outer surface of the polystyrene extruded board 2, and the plastering anti-cracking layer 3 is a flat layer on the outer surface made of cement mortar;

[0052] Step 2, snapping the grid sutures: according to the needs, pop the grid sutures on the outer surface of the anti-crack layer 3 of the plastering surface, and after the grid sutures are completed, the Paste masking paper on the position, and the masking paper coincides with the grid stitching;

[0053] The following are the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com