Surface acoustic wave pressure sensor based on loss detection

A pressure sensor and surface acoustic wave technology, which is applied in the measurement of force, the measurement of the property force of piezoelectric devices, and instruments, etc., can solve the problems of large differences in sensor performance, difficult reference cavity packaging, and low sensor yield. , to achieve the effect of improving out-of-band suppression capability, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

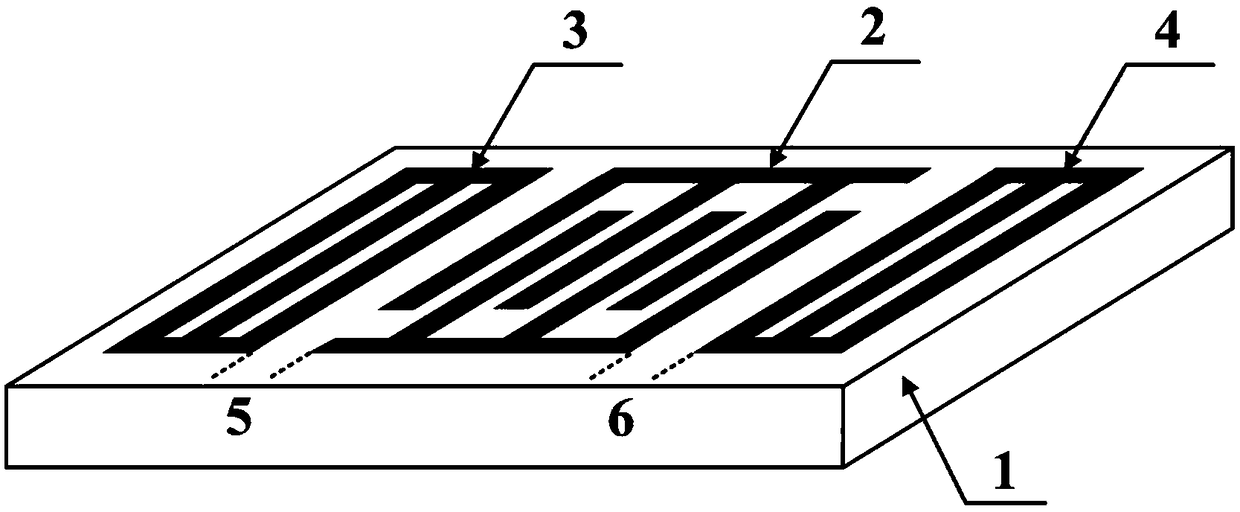

[0042]The AT-X quartz (Euler angle (0°, -54.7°, 0°)) piezoelectric sheet is used as the substrate 1, and the interdigital transducer 2 is arranged at the center of the substrate 1, and the interdigital transducer The first metal reflective grating array 3 and the second metal reflective grating array 4 are arranged in parallel on both sides of the device 2, the interdigital transducer 2 and the first metal reflective grating array 3 form a space 5, the interdigital transducer 2 and the second metallic reflective grating array The two metal reflective grating arrays 4 form a space 6, and the bus bars at both ends of the IDT 2 are connected with output leads. The interdigital transducer 2 , the first metal reflective grating array 3 and the second metallic reflective grating array 4 are not weighted.

[0043] The metallization ratios of the interdigital transducer 2 , the first metal reflection grid array 3 and the second metal reflection grid array 4 are equal, and the metalliz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com