Beet leaf paraffin-embedded sectioning method

A technology of paraffin embedding and sugar beet leaves, which is applied in the preparation of test samples, etc., can solve the problems of reduced work efficiency, non-slicing of slices, and heavy workload, so as to save time, improve work efficiency, and improve film production efficiency and The effect on success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

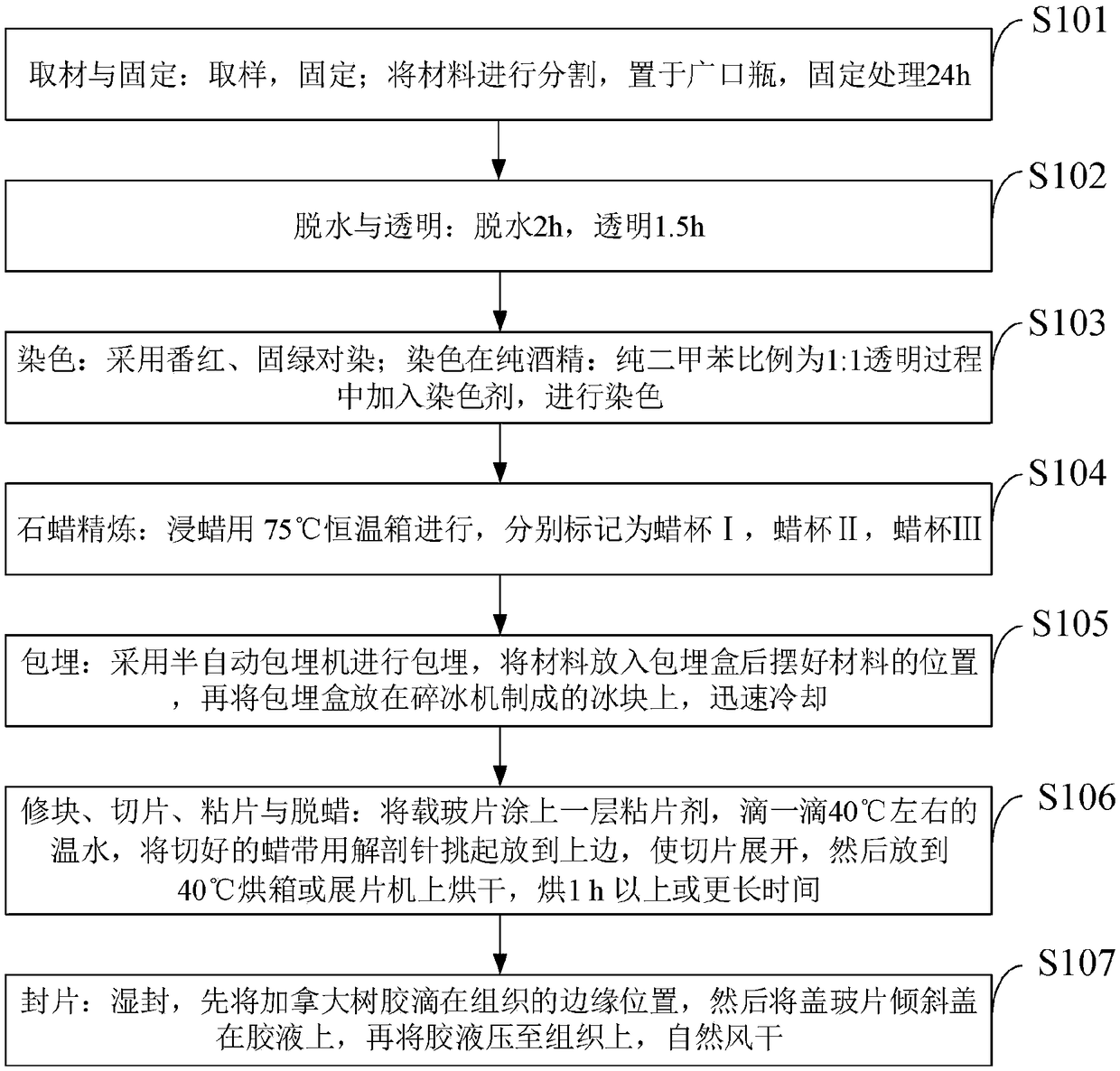

[0068] 1. Production:

[0069] (1) Dehydration and clearing: The correlation between dehydration time and clearing time is clarified, that is, the longer the dehydration time, the shorter the clearing time. In this experiment, the dehydration time was 2 hours, and the clearing time was 1.5 hours.

[0070] (2) Dyeing: The traditional dyeing method is to add dyeing agent when 70% alcohol is dehydrated. However, in the actual operation process, even if it is left overnight, the dyed material will be washed away in the subsequent step-by-step high-concentration alcohol. In the end, almost all of them are decolorized. This experiment finds out that the best effect is to add dyeing agent in the transparent process of 1:1 pure alcohol: pure xylene.

[0071] (3) Paraffin wax selection and refining: The experiment compared the embedding effects of two paraffin waxes with specifications 52-54, melting point 51-55 and specifications 54-56, melting point 53-57, and screened out specificat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com