Corrosion-resistant aluminum plastic film for lithium battery

An anti-corrosion, aluminum-plastic film technology, used in batteries, battery pack parts, battery boxes/jackets, etc., can solve the problems of the mechanical properties of aluminum-plastic film decline, poor safety of lithium battery use, damage to packaging structure, etc., to achieve isolation Electrolyte, the effect of improving tensile strength at break and compressive performance, and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

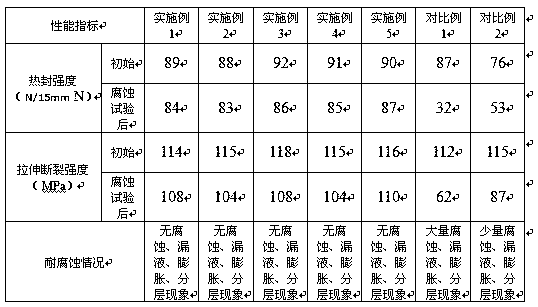

Examples

Embodiment 1

[0027] The anti-corrosion aluminum-plastic film includes a protective layer, an aluminum foil layer and a heat-sealing layer; the thickness of the protective layer is 20 μm; the thickness of the aluminum foil layer is 40 μm; the thickness of the heat-sealing layer is 60 μm.

[0028] The protective layer is a polystyrene layer, which is bonded and compounded with the aluminum foil layer through an adhesive layer; the adhesive layer is an epoxy resin adhesive layer;

[0029] The aluminum foil layer and the heat-sealing layer are laminated by hot pressing;

[0030] The material of the heat-sealing layer is a three-layer co-extruded composite film, the inner layer is a bonding layer, the middle layer is a structural layer, and the outer layer is a barrier layer; wherein, the material of the bonding layer is vinyltrimethoxysilane Bonding layer; the material of the structural layer is composed of 40 parts by weight of fluorinated polyvinyl chloride, 65 parts by weight of perfluoroet...

Embodiment 2

[0032] The anti-corrosion aluminum-plastic film includes a protective layer, an aluminum foil layer and a heat-sealing layer; the thickness of the protective layer is 50 μm; the thickness of the aluminum foil layer is 20 μm; the thickness of the heat-sealing layer is 50 μm.

[0033] The protective layer is a polystyrene layer, which is bonded and compounded with the aluminum foil layer through an adhesive layer; the adhesive layer is an epoxy resin adhesive layer;

[0034] The aluminum foil layer and the heat-sealing layer are laminated by hot pressing;

[0035] The material of the heat-sealing layer is a three-layer co-extruded composite film, the inner layer is a bonding layer, the middle layer is a structural layer, and the outer layer is a barrier layer; wherein, the material of the bonding layer is vinyltrimethoxysilane Bonding layer; the material of the structural layer is composed of 30 parts by weight of fluorinated polyvinyl chloride, 50 parts by weight of perfluoroet...

Embodiment 3

[0037] The anti-corrosion aluminum-plastic film includes a protective layer, an aluminum foil layer and a heat-sealing layer; the thickness of the protective layer is 30 μm; the thickness of the aluminum foil layer is 30 μm; the thickness of the heat-sealing layer is 80 μm.

[0038] The protective layer is a polystyrene layer, which is bonded and compounded with the aluminum foil layer through an adhesive layer; the adhesive layer is an epoxy resin adhesive layer;

[0039] The aluminum foil layer and the heat-sealing layer are laminated by hot pressing;

[0040] The material of the heat-sealing layer is a three-layer co-extruded composite film, the inner layer is a bonding layer, the middle layer is a structural layer, and the outer layer is a barrier layer; wherein, the material of the bonding layer is vinyltrimethoxysilane Bonding layer; the material of the structural layer is composed of 40 parts by weight of fluorinated polyvinyl chloride, 50 parts by weight of perfluoroet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com