Straw functional beverage and preparation method thereof

A functional and straw technology, applied in the field of straw functional beverage and its preparation, can solve problems such as unfavorable health, and achieve the effects of good market prospects, less by-products, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

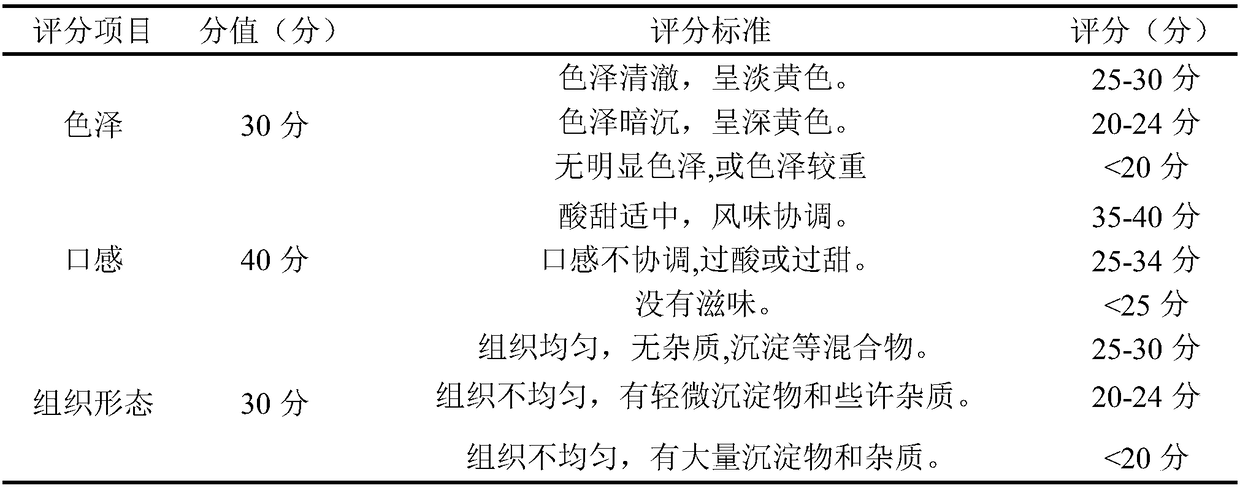

Examples

Embodiment 1

[0029] A method for preparing a straw functional beverage, comprising the following steps:

[0030] (1) Preparation of dry corn stalk raw materials: cut 10g of dry corn stalks to a size of about 3cm, remove dust and impurities on the surface, and obtain dry corn stalk raw materials; too long straws will affect the operation of subsequent steps;

[0031] (2) Water immersion: soak the prepared dry corn stalk raw material with distilled water for 24 hours, then filter and collect the filter residue for later use, and the filter residue is marked as No. 1 filter residue; the soaking process requires distilled water to submerge the dry corn stalk raw material, so that not only Impurities such as dust can be removed, and the tissue of the dry corn stalk raw material can be softened to facilitate the operation in subsequent steps;

[0032] (3) Drying and crushing: put the No. 1 filter residue into a constant temperature drying box for drying, and then crush it to 80 mesh to obtain st...

Embodiment 2

[0063] A method for preparing a straw functional beverage, comprising the following steps:

[0064] (1) Preparation of dry corn stalk raw materials: cut 10g of dry corn stalks to a size of about 3cm, remove dust and impurities on the surface, and obtain dry corn stalk raw materials; too long straws will affect the operation of subsequent steps;

[0065] (2) Water immersion: soak the prepared dry corn stalk raw material with distilled water for 24 hours, then filter and collect the filter residue for later use, and the filter residue is marked as No. 1 filter residue; the soaking process requires distilled water to submerge the dry corn stalk raw material, so that not only Impurities such as dust can be removed, and the tissue of the dry corn stalk raw material can be softened to facilitate the operation in subsequent steps;

[0066] (3) Drying and crushing: put the No. 1 filter residue into a constant temperature drying box for drying, and then crush it to 80 mesh to obtain st...

Embodiment 3

[0085] A method for preparing a straw functional beverage, comprising the following steps:

[0086] (1) Preparation of dry corn stalk raw materials: cut 10g of dry corn stalks to a size of about 3cm, remove dust and impurities on the surface, and obtain dry corn stalk raw materials; too long straws will affect the operation of subsequent steps;

[0087] (2) Water immersion: soak the prepared dry corn stalk raw material with distilled water for 24 hours, then filter and collect the filter residue for later use, and the filter residue is marked as No. 1 filter residue; the soaking process requires distilled water to submerge the dry corn stalk raw material, so that not only Impurities such as dust can be removed, and the tissue of the dry corn stalk raw material can be softened to facilitate the operation in subsequent steps;

[0088] (3) Drying and crushing: put the No. 1 filter residue into a constant temperature drying box for drying, and then crush it to 80 mesh to obtain st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com