Microwave heat pump low-oxygen drying device and operating method thereof

A technology of drying equipment and operation method, which is applied in lighting and heating equipment, drying gas arrangement, local stirring dryer, etc. ingredients, improving drying efficiency, preventing oxidative browning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

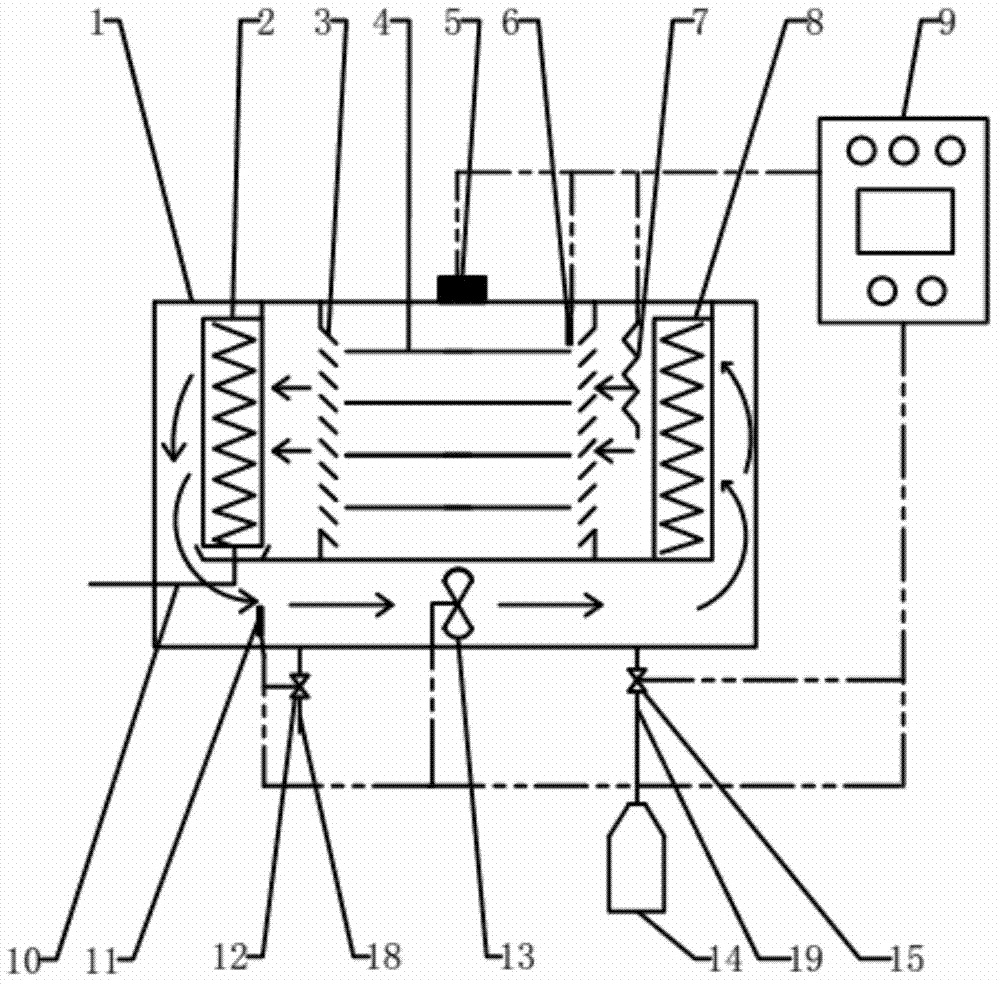

[0045] Such as figure 1 As shown, the microwave heat pump hypoxic drying equipment of the present invention includes a box body 1 , a control box 9 and a carbon dioxide source 14 .

[0046] Wherein, a microwave generator 5 is arranged on the box body 1, and the microwave generator 5 is electrically connected with the control box 9 to realize the setting and adjustment of the microwave power.

[0047] A material rack 4 , a heat pump system, a temperature sensor 6 , a heating wire 7 , an oxygen concentration sensor 11 , and a fan 13 are respectively arranged inside the box body 1 .

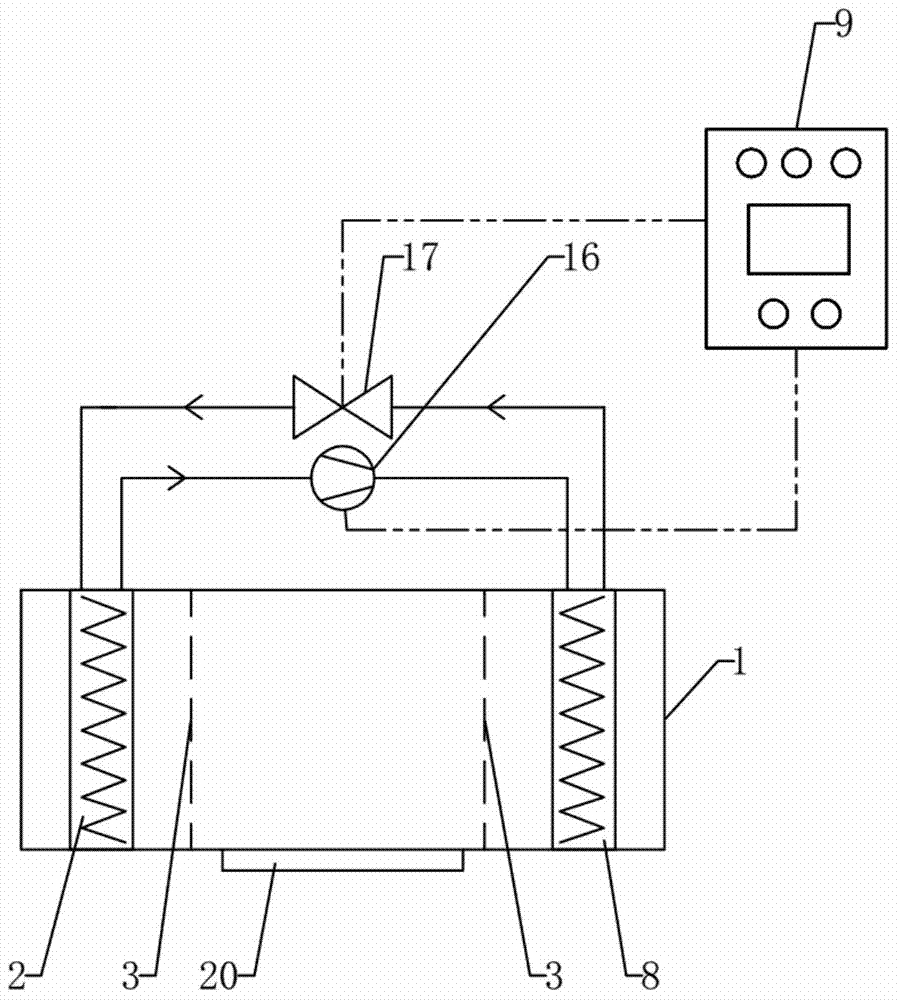

[0048] Among them, such as figure 2 As shown, the heat pump system includes an evaporator 2, a condenser 8, a compressor 16, and an expansion valve 17, wherein the evaporator 2 and the condenser 8 are respectively located at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com