Impregnation equipment and method for preparing organic tail gas treatment catalytic incineration catalyst by using impregnation equipment

An impregnation equipment and tail gas treatment technology, which is applied in the field of organic tail gas treatment catalysts and its preparation equipment, can solve the problems of difficult impregnation of the carrier, achieve the effects of uniform distribution, simplify the preparation process, and reduce chemical odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

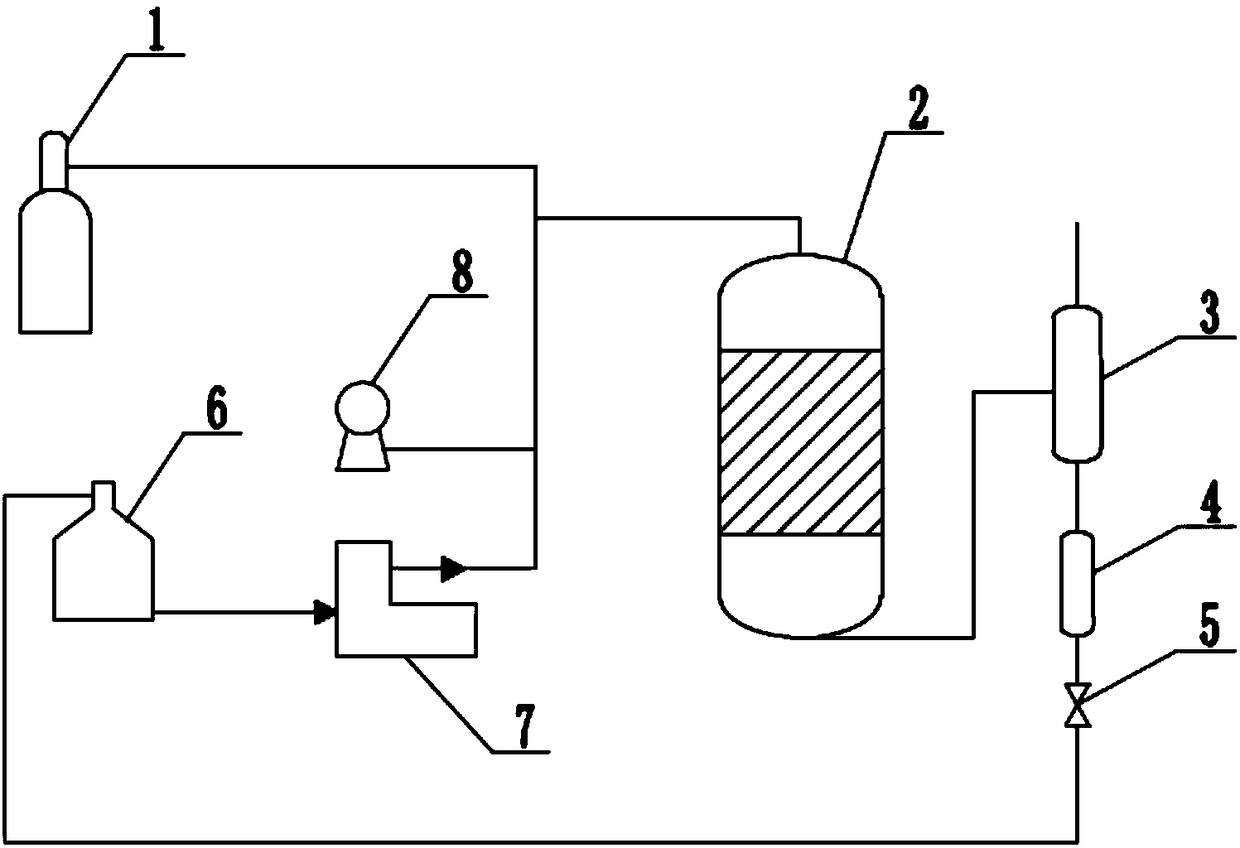

Method used

Image

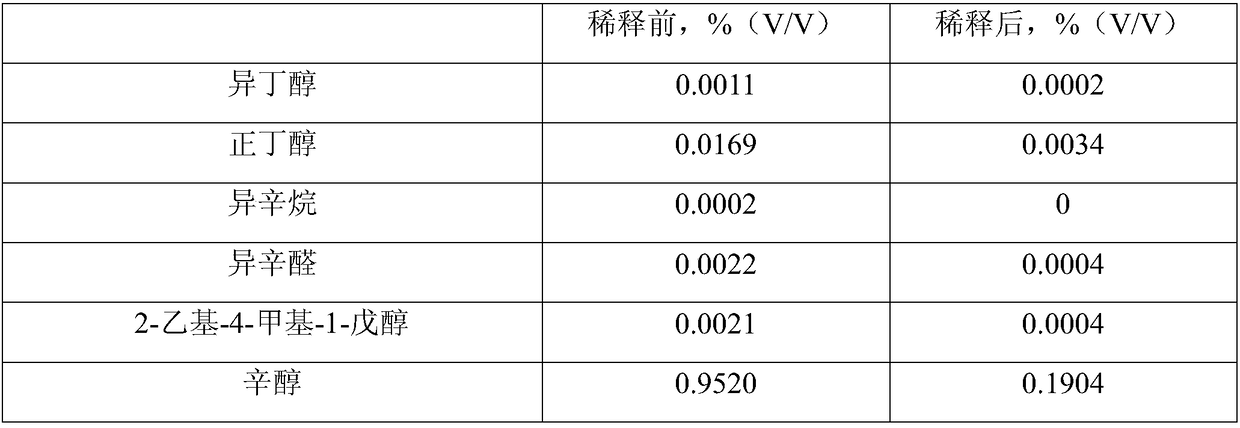

Examples

Embodiment 1

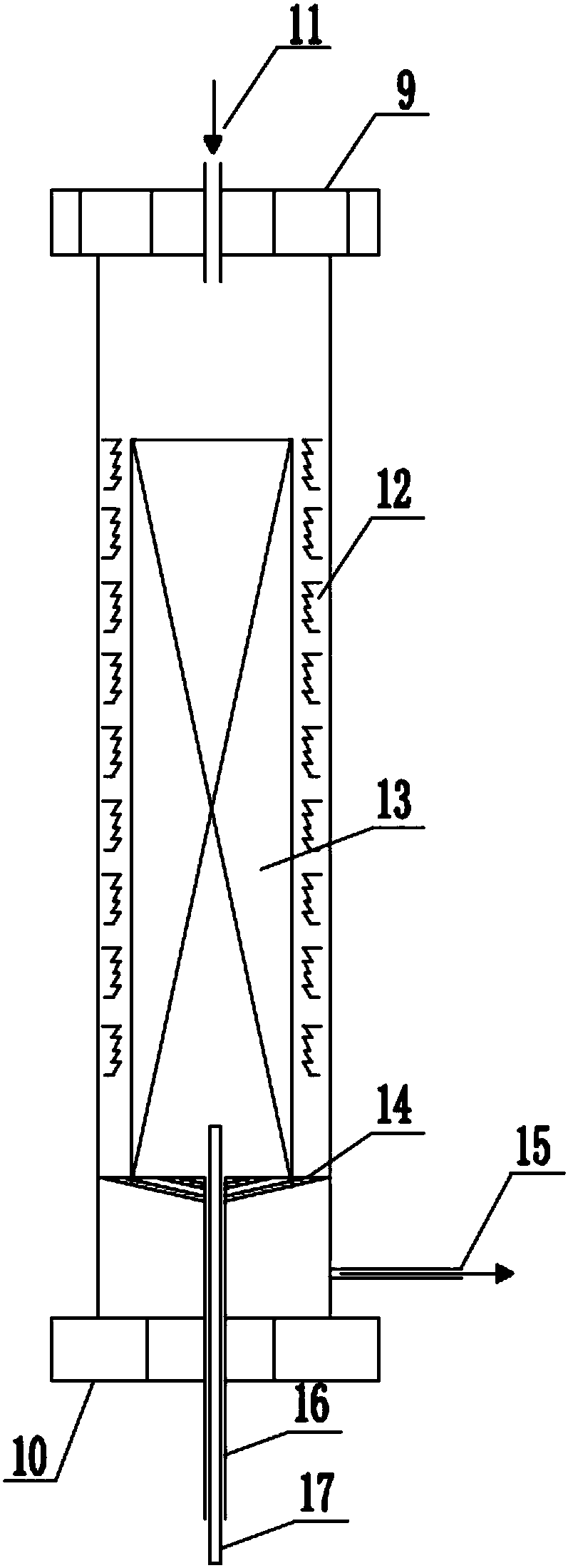

[0051] Place the cordierite monolithic honeycomb carrier 13 on the tray 14 in the autoclave 2, close the autoclave 2, open the gas cylinder 1, and purge the carrier 13 with 1.0MPa nitrogen to remove the impurities attached to the surface of the carrier 13 from the system , after purging for 60 minutes, turn off the nitrogen.

[0052] Raise the temperature to 150°C, turn on the vacuum pump 8, in a vacuum of 5×10 -2 Carrier 13 was degassed for 60 minutes under certain conditions. After completing the degassing, stop the vacuum pump 8, stop heating, and the system is down to normal temperature.

[0053] Turn on the water pump 7, inject the desalted water into the autoclave 2, the system pressure is normal pressure, immerse the carrier 13 in the desalted water for 60 minutes, then empty the water in the system, and use 1.0MPa nitrogen to blow the carrier 1310 minutes to reduce its Residual moisture attached to the surface.

Embodiment 2

[0062] Place the cordierite monolithic honeycomb carrier 13 on the tray 14 in the autoclave 2, close the autoclave 2, open the gas cylinder 1, and purge the carrier 13 with 0.5MPa nitrogen to remove the impurities attached to the surface of the carrier 13 from the system , after purging for 30 minutes, turn off the nitrogen.

[0063] Raise the temperature to 120°C, turn on the vacuum pump 8, in a vacuum of 1×10 -1 Carrier 13 was degassed for 30 minutes under certain conditions. After completing the degassing, stop the vacuum pump 8, stop heating, and the system is down to normal temperature.

[0064] Turn on the water pump 7, inject the desalted water into the autoclave 2, the system pressure is normal pressure, immerse the carrier 13 in the desalted water for 30 minutes, then empty the water in the system, and use 0.5MPa nitrogen to blow the carrier for 135 minutes to reduce its Residual moisture attached to the surface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com