Double-passage eccentricity preventing overload protector

An overload and dual-channel technology, applied in metal processing equipment, safety equipment, manufacturing tools, etc., can solve problems such as oil pump overload, equipment overload, and low oil output from the pump head, etc. Simplicity, the effect of simple pump head design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the technical means of the present invention and the technical effects that can be achieved more clearly and more completely disclosed, an embodiment is provided hereby, and the following detailed description is given in conjunction with the accompanying drawings:

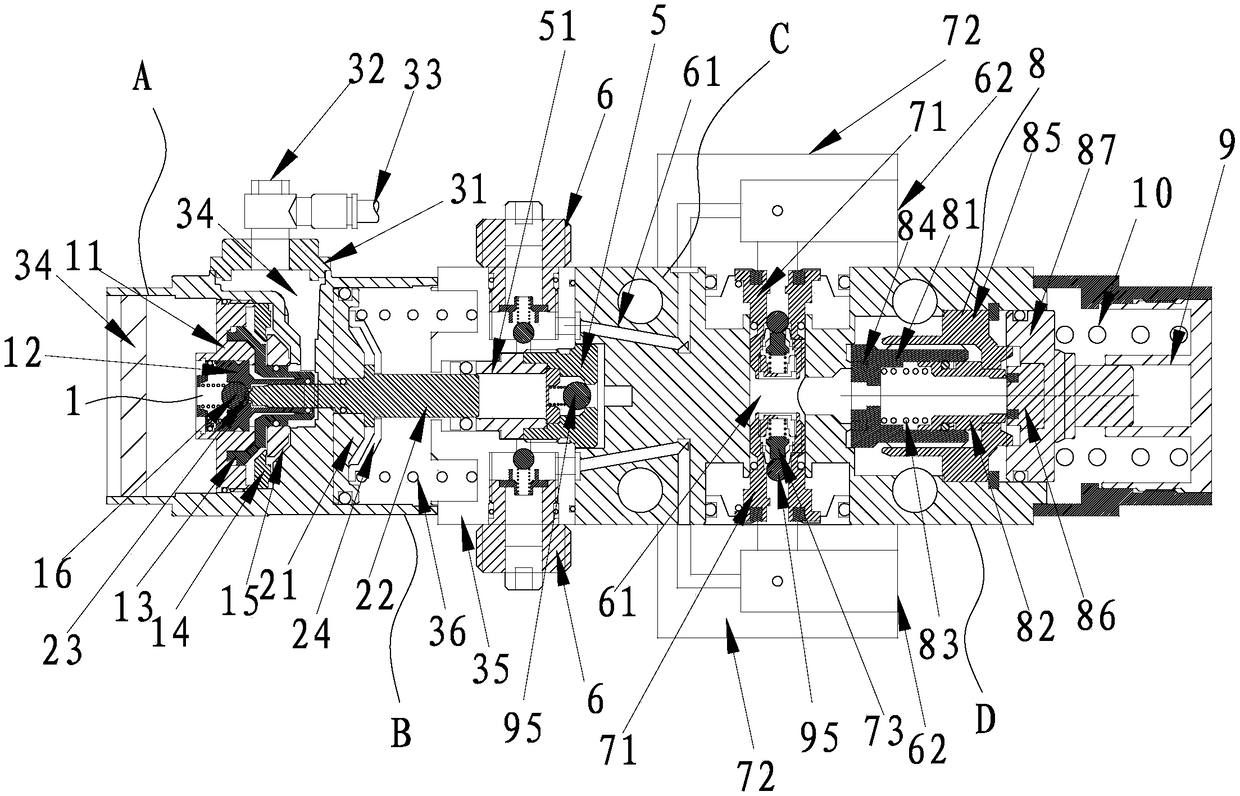

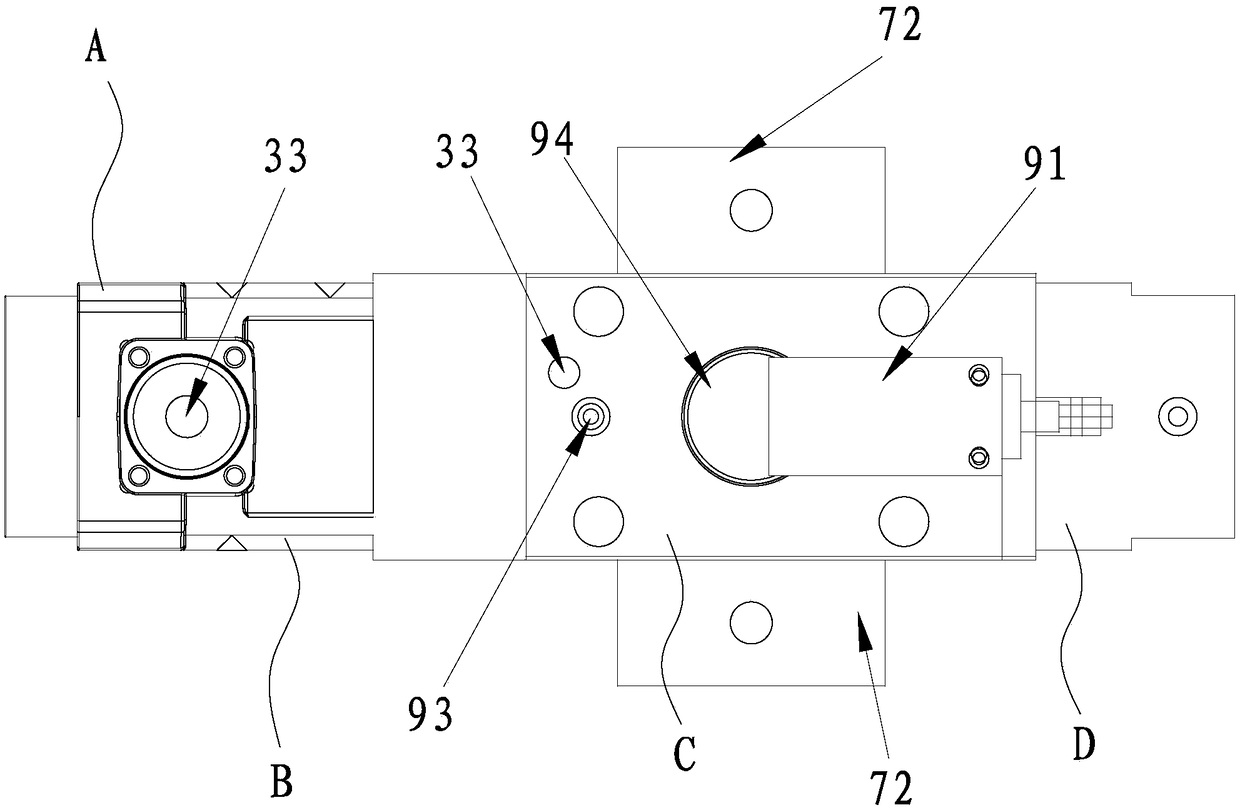

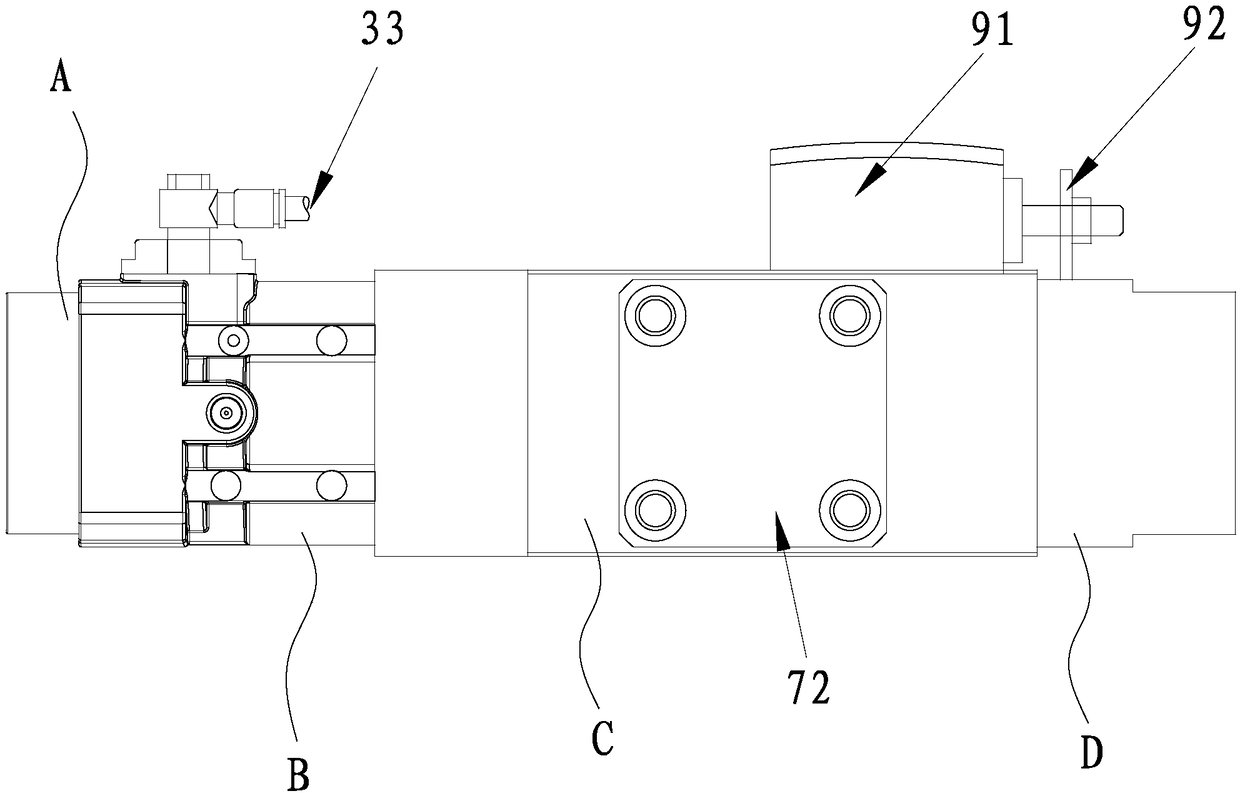

[0035] Such as Figure 1-3 As shown, the dual-channel anti-eccentric overload protector of this embodiment includes cylinder block A, cylinder block B, oil pressure seat C and pressure relief seat D combined in sequence, and the pneumatic Pump, oil suction valve 5 and oil outlet valve 6 in oil pressure seat C, corresponding oil pressure suction port, oil pressure output port 62, oil discharge valve 8 in pressure relief seat D and corresponding discharge port, The pressure relief piston 87, the electric circuit of the travel switch and the air pressure inlet 33 arranged in the pressure relief seat D, and the anti-bias load mechanism arranged on the oil pressure seat C. The anti-eccentric loa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com