Ship fresh water tank anti-freezing system

A technology of antifreeze system and fresh water tank, which is applied in the direction of fresh water production equipment, ship parts, ship construction, etc., can solve the problems of high construction cost, compressed air mixed with a small amount of oil gas and impurities, and harsh working environment, so as to reduce construction cost, The effect of saving construction man-hours and implementing low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

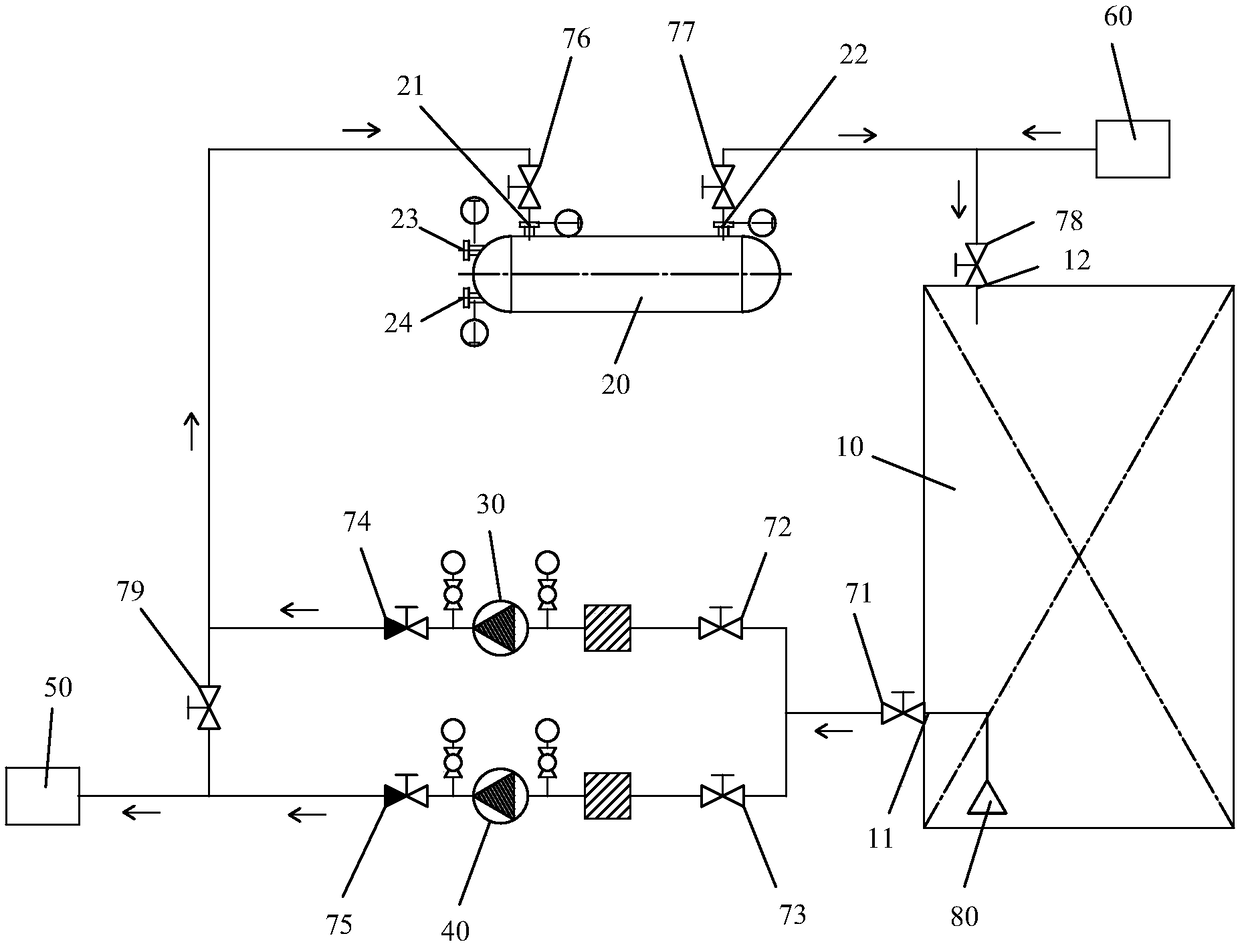

[0020] Hereinafter, the present invention will be more clearly and completely described with reference to a preferred embodiment and in conjunction with the accompanying drawings.

[0021] like figure 1 As shown, an anti-freezing system for a fresh water tank of a ship includes a heat exchanger 20 arranged outside the fresh water tank 10; a first daily fresh water pump 30 is arranged between the fresh water tank 10 and the heat exchanger 20; The water inlet 11 is connected to the first day fresh water pump 30 ; the first day fresh water pump 30 is connected to the water inlet 21 of the heat exchanger 20 ; the water outlet 22 of the heat exchanger 20 is connected to the water inlet 12 of the fresh water tank 10 .

[0022] The water outlet 11 of the fresh water tank 10 is connected with a first cut-off valve 71; the two ends of the first day-use fresh water pump 30 are respectively provided with a second cut-off valve 72 and a fourth cut-off check valve 74, and the second cut-of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com