Demulsification method for oil-in-water emulsion, and process

An oil-in-water, emulsion technology, which is applied in the field of demulsification of oil-in-water emulsions, can solve the problems of environmental hazards, long time consumption, large floor space, etc., and achieves the effect of good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

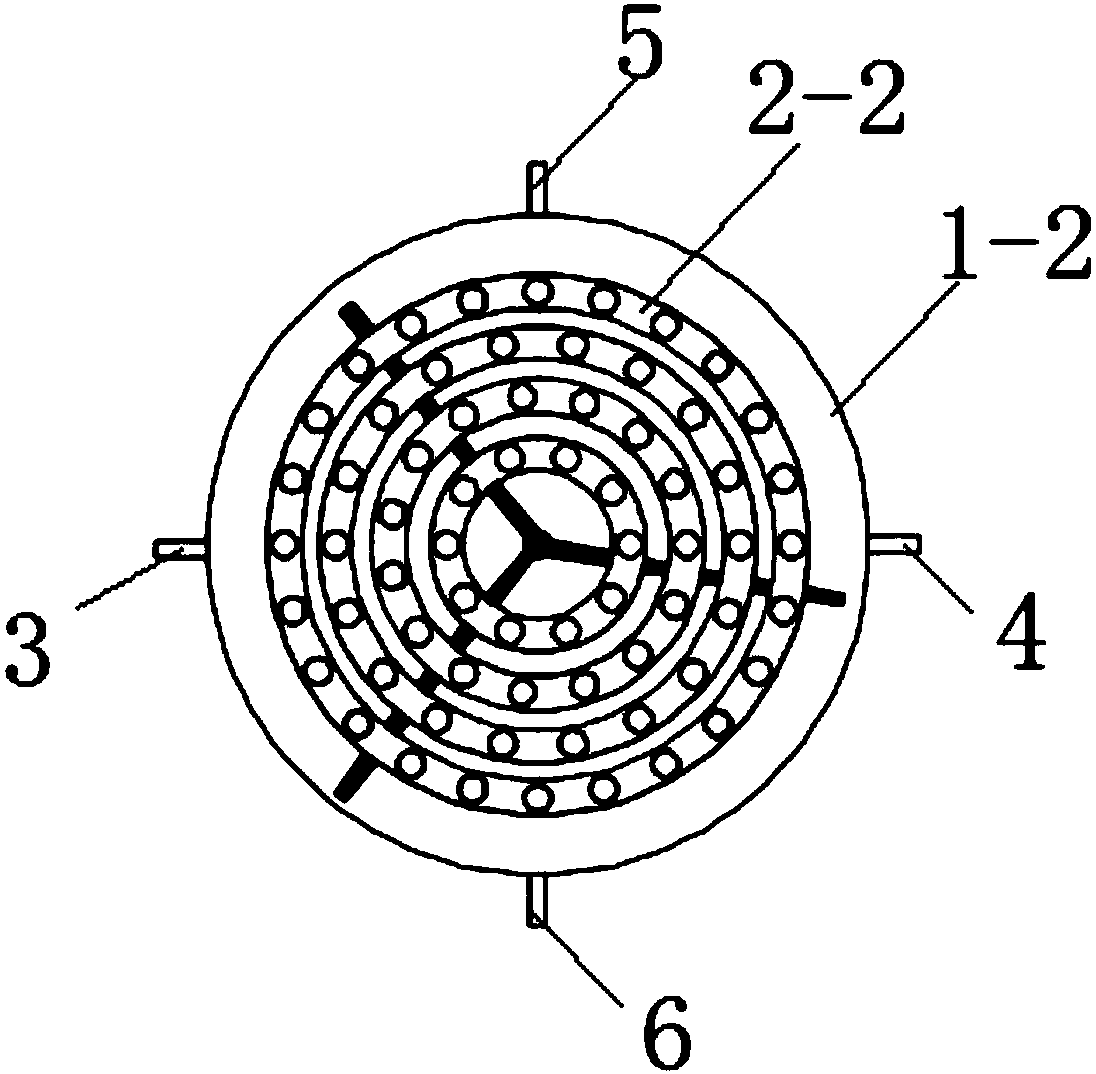

[0050] Take 300mL of water-in-diesel emulsion (diesel oil is commercially available 0#), and the oil content is 0.5%. The electric field form selects bidirectional pulsed electric field, the waveform is square wave, the voltage is set to 900V, the frequency is set to 50Hz, the total duty cycle is set to 0.5, and the positive and negative duty cycle is set to 0.5. The main body of the oil-water separator is a circular cylinder, and the electrode assembly is an integral ring-shaped electrode assembly (see Figure 9 and Figure 10 ), the number of single electrodes installed is 47, the angle difference between adjacent electrodes is 30°, the diameter of a single electrode is 5mm, the distance between the electrode assembly and the inner wall of the oil-water separator is kept at 12mm, and a metal The electrode serves as the positive pole, and the rest serve as the negative pole. After the electric field was applied for 2 hours, the efficiency of demulsification and oil removal ...

Embodiment 2

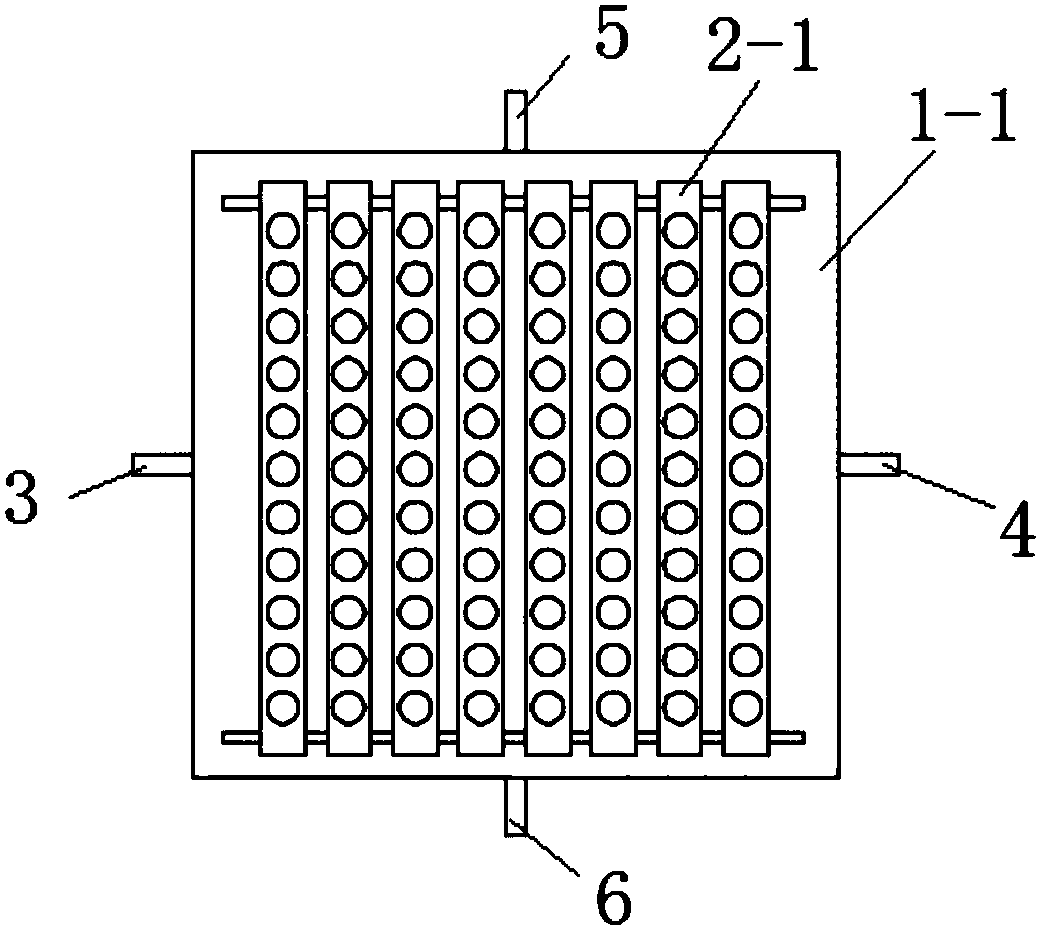

[0052] Take 300mL of water-in-diesel emulsion (diesel oil is commercially available 0#), and the oil content is 0.5%. The electric field form selects positive pulse electric field, the waveform is square wave, the voltage is set to 1000V, the frequency is set to 50Hz, the total duty cycle is set to 0.3, and the positive and negative duty cycle is set to 0.5. The main body of the oil-water separator is a square cylinder, and the electrode assembly is an integrated rectangular arrangement of electrode assemblies (see Figure 7 and Figure 8 ), the number of single electrodes installed is 50, the distance between adjacent electrodes is 10mm, and the diameter of a single electrode is 5mm. The distance between the electrode assembly and the inner wall of the oil-water separator is kept at 15 mm, and the four rod-shaped metal electrodes located in the center of the orifice plate are used as positive electrodes, and the rest are used as negative electrodes. After the electric field...

Embodiment 3

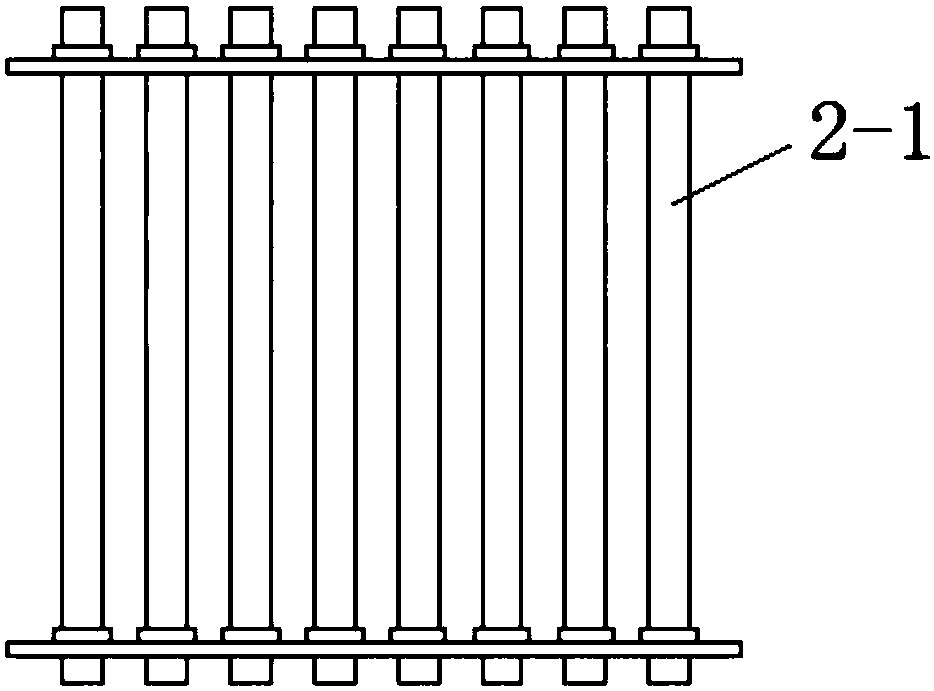

[0054] Take 300mL of water-in-diesel emulsion (diesel oil is commercially available 0#), and the oil content is 1%. The electric field form is pulsed AC electric field, the waveform is a rectangular wave, the voltage is set to 800V, the frequency is set to 50Hz, the total duty cycle is set to 0.5, and the positive and negative duty cycle is set to 0.3. The main body of the oil-water separator is a square cylinder, and the electrode assembly is a split rectangular electrode assembly 2-1 (see image 3 and Figure 4 ), the number of small units installed is 8, the number of single electrodes installed is 64, the distance between adjacent electrodes is 5mm, and the diameter of a single electrode is 5mm. The distance between the electrode assembly and the inner wall of the oil-water separator is kept at 10mm. The metal electrodes of 1-10 small units located on the left side of the electrode assembly are used as positive electrodes, and the rest are used as negative electrodes. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com