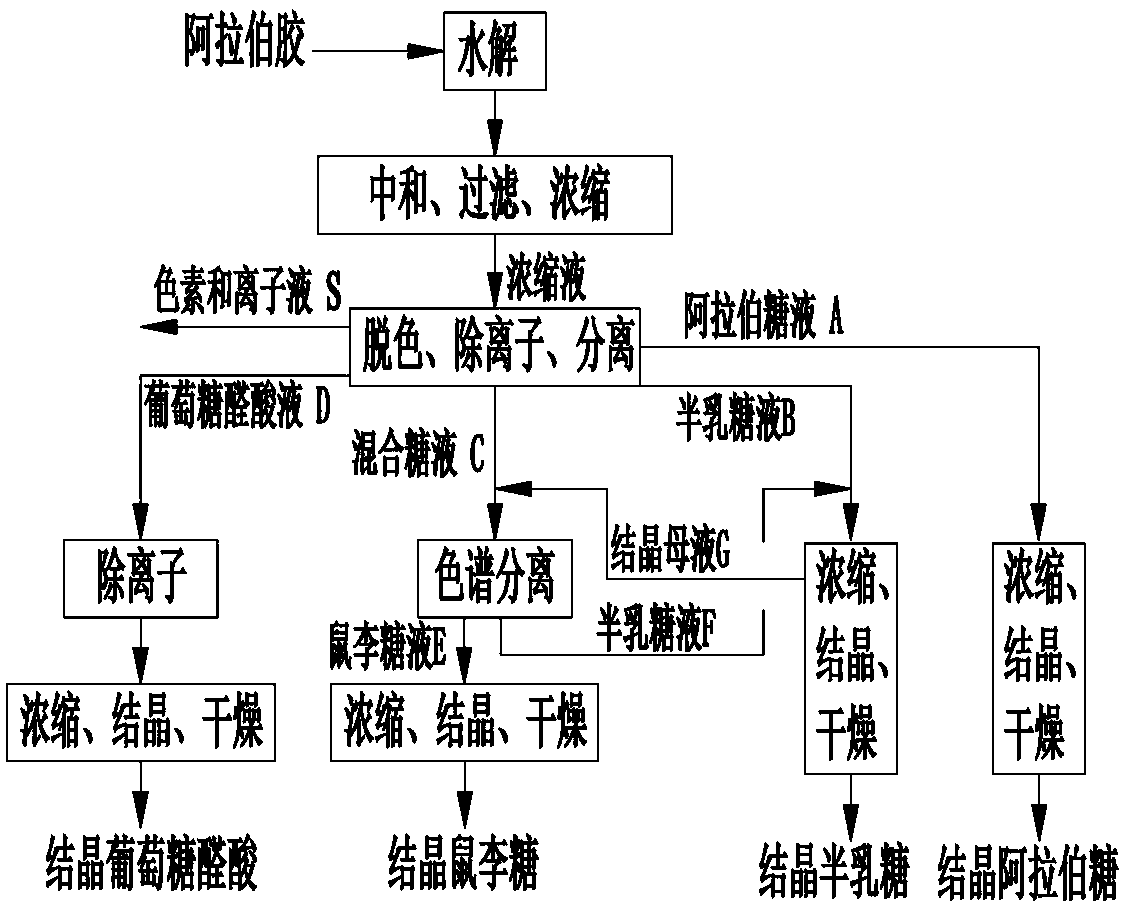

Method for preparing arabinose, galactose, rhamnose and glucuronic acid

A technology of glucuronic acid and arabinose, which is applied in the production field of galactose, arabinose, rhamnose and glucuronic acid to achieve high efficiency, high raw material utilization rate and short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

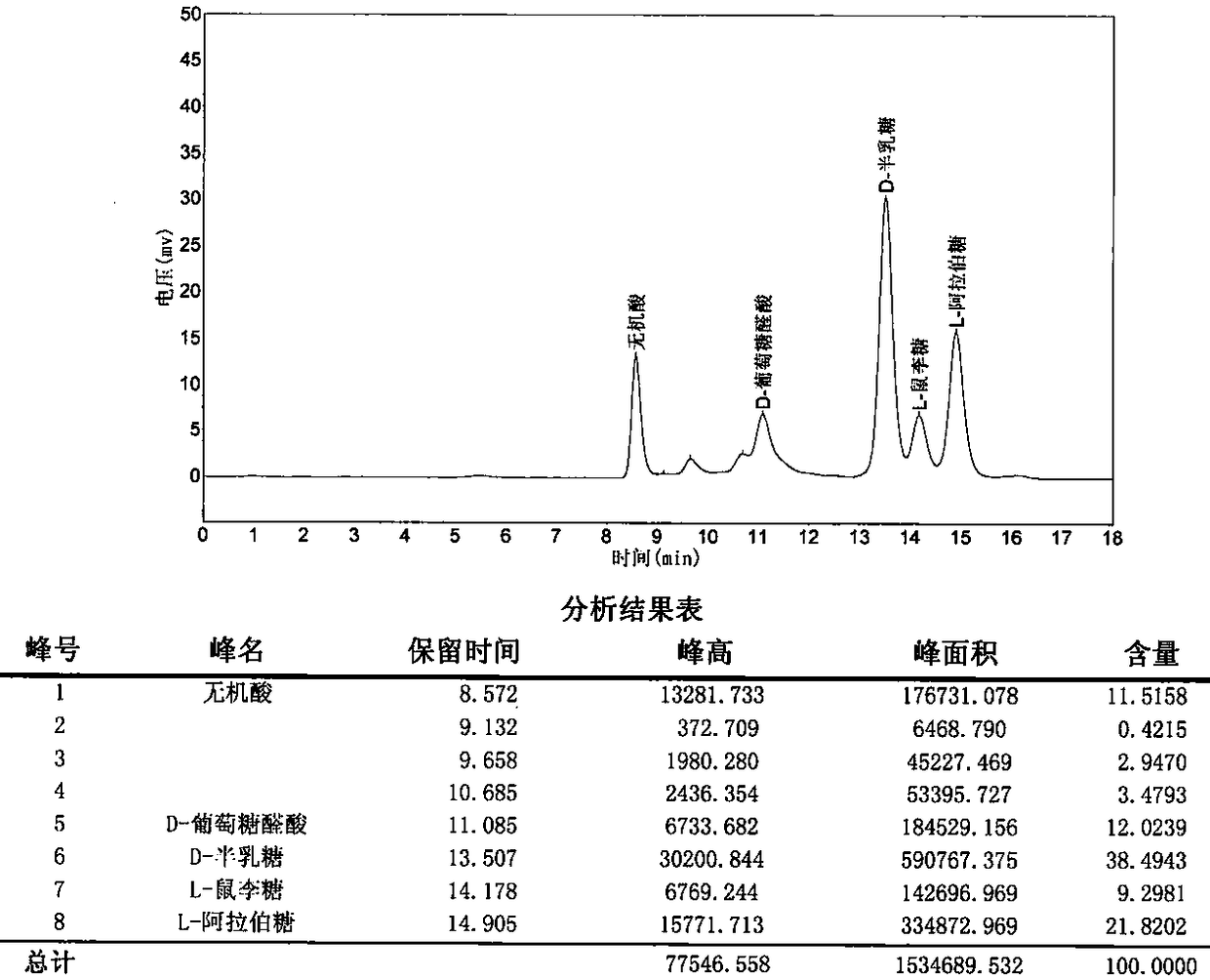

Method used

Image

Examples

Embodiment 1

[0054] Example 1, crush the gum arabic, dissolve it at 30-40°C, adjust it to a mass percentage concentration of 25%, add dilute sulfuric acid to adjust the pH value of the solution to 0.3, and hydrolyze it at a temperature of 105°C for 12 hours to obtain a hydrolyzed solution; The solution was left to stand for 1-2 hours, and the supernatant was filtered and neutralized with alkali to a pH value of 4.0-5.0, then filtered and concentrated to obtain a concentrated solution.

Embodiment 2

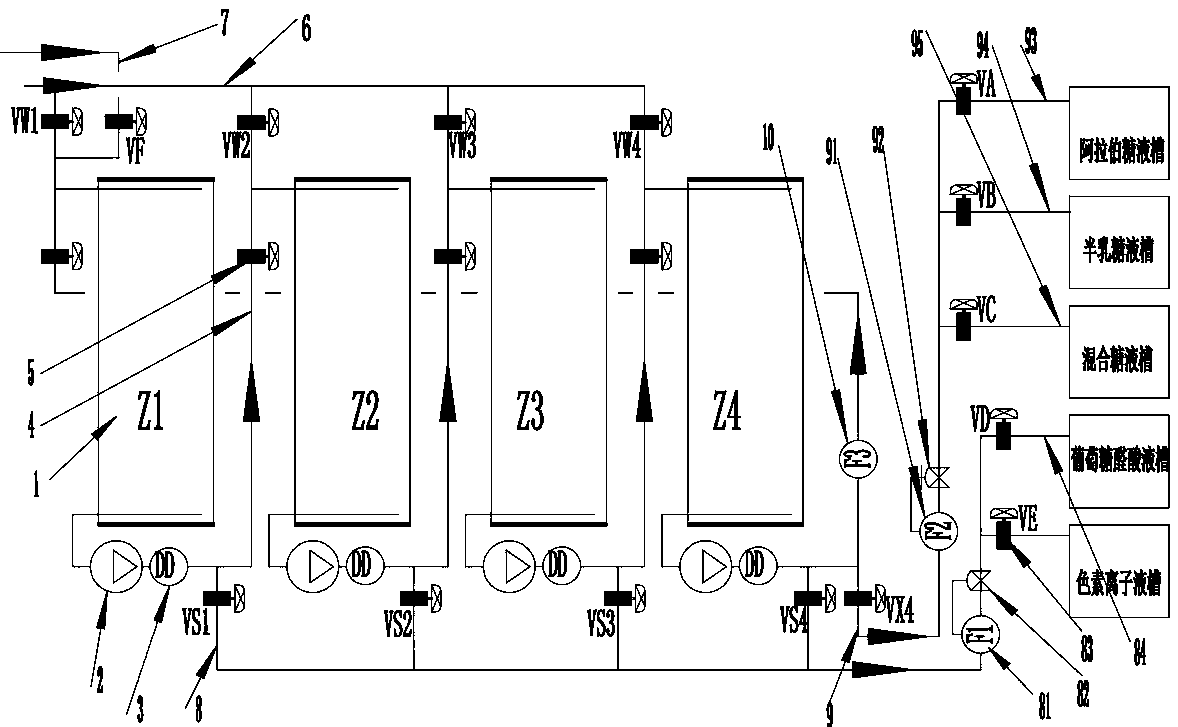

[0055] Embodiment 2, the device for decolorization and deionization used in the present invention to separate the mixture simultaneously, as attached image 3 As shown, it consists of chromatographic column 1, booster pump 2, conductivity meter 3, connecting pipe 4, isolation valve 5, eluent pipe 6, material pipe 7, circulation flow meter 10; raffinate pipe 8, raffinate flow rate Meter 81, raffinate flow regulating valve 82, pigment and ionic liquid branch 83, glucuronic acid liquid branch 84; extracting liquid pipe 9, extracting liquid flow meter 91, extracting liquid flow regulating valve 92, arabinose liquid branch 93, galactose solution branch 94, mixed sugar solution branch 95; there are also arabinose solution tank, galactose solution tank, mixed sugar solution tank, glucuronic acid solution tank and pigment and ionic liquid tank; each chromatographic column The inlet is connected with eluent valves VW1~VW4; the inlet of the first chromatographic column is connected with...

Embodiment 3

[0058] Example 3, the operation process of the device for decolorizing and deionizing while separating the mixture described in Example 2 includes three processes: feeding, elution, and internal circulation.

[0059] The device operates periodically. For a chromatographic system composed of 4 chromatographic columns in series, the column numbers are Z1, Z2, Z3, and Z4. Each cycle is divided into 10 processes, starting from process 1, going to process 10, and then returning to process 1. Continuous cycle; 10 processes are as follows:

[0060] Process 1: Z1 feeds the material, and Z4 lowers the rich mixed sugar solution C, and enters the extraction liquid pipe 9, passes through the extraction liquid flow meter 91, the extraction liquid flow regulating valve 92, enters the mixed sugar liquid branch 95, and passes through the VC After the valve, it enters the mixed sugar solution tank.

[0061] Process 2: Z1 feeds material, Z1 discharges rich glucuronic acid liquid D, and enters ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com