Copper alloy metallographic corrosion solution and corrosion method thereof

A metallographic corrosion and copper alloy technology, which is applied in the field of metallographic etching solution of copper alloys, can solve the problems of insufficient display of grain boundaries, unclear grain boundaries, short corrosion time, etc., and achieves easy control of corrosion degree and metallographic structure. Clear structure and strong corrosion depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

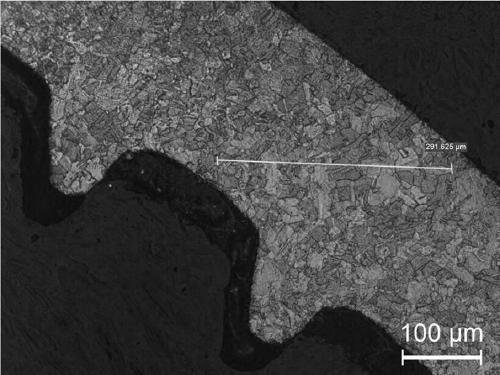

Embodiment 1

[0018] The metallographic corrosion solution of copper alloy is composed of the following components by volume percentage: 89.29% potassium dichromate saturated aqueous solution, 8.93% concentrated sulfuric acid, 1.78% sodium chloride saturated aqueous solution (potassium dichromate saturated aqueous solution: concentrated sulfuric acid : saturated aqueous solution of sodium chloride=100ml:10ml:2ml). This ratio is the best ratio for corrosion. The concentrated sulfuric acid is composed of the following components in volume percentage: 96.5% H 2 SO 4 , and the rest is water.

[0019] The metallographic corrosion method of copper alloy is to use absorbent cotton to dip the above metallographic corrosion solution along the direction of the copper alloy, and wipe the surface of the sample twice continuously and quickly, and rinse the copper alloy sample with water within 2 seconds after wiping, and rinse it clean. After drying, a copper alloy metallographic sample was obtained....

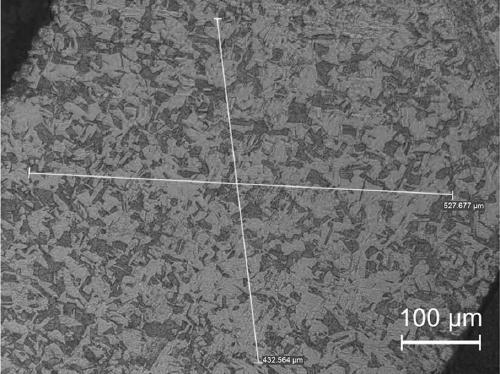

Embodiment 2

[0021] The metallographic corrosion solution of copper alloy is composed of the following components by volume percentage: 89% potassium dichromate saturated aqueous solution, 9% concentrated sulfuric acid, and 2% sodium chloride saturated aqueous solution. The concentrated sulfuric acid is composed of the following components in volume percentage: 95-98% H 2 SO 4 , and the rest is water.

[0022] The metallographic corrosion method of copper alloy is to use absorbent cotton to dip the above metallographic corrosion solution along the direction of the copper alloy, and wipe the surface of the sample twice continuously. After wiping, the copper alloy sample is rinsed with water within 2 seconds. Dry to obtain a copper alloy metallographic sample.

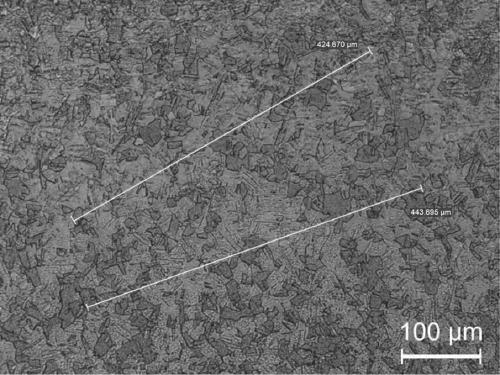

Embodiment 3

[0024] The metallographic corrosion solution of copper alloy is composed of the following components in volume percentage: 90% potassium dichromate saturated aqueous solution, 8% concentrated sulfuric acid, and 2% sodium chloride saturated aqueous solution. The concentrated sulfuric acid is composed of the following components in volume percentage: 95-98% H 2 SO 4 , and the rest is water.

[0025] The metallographic corrosion method of copper alloy is to use absorbent cotton to dip the above metallographic corrosion solution along the direction of the copper alloy, and wipe the surface of the sample twice continuously. After wiping, the copper alloy sample is rinsed with water within 2 seconds. Dry to obtain a copper alloy metallographic sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com