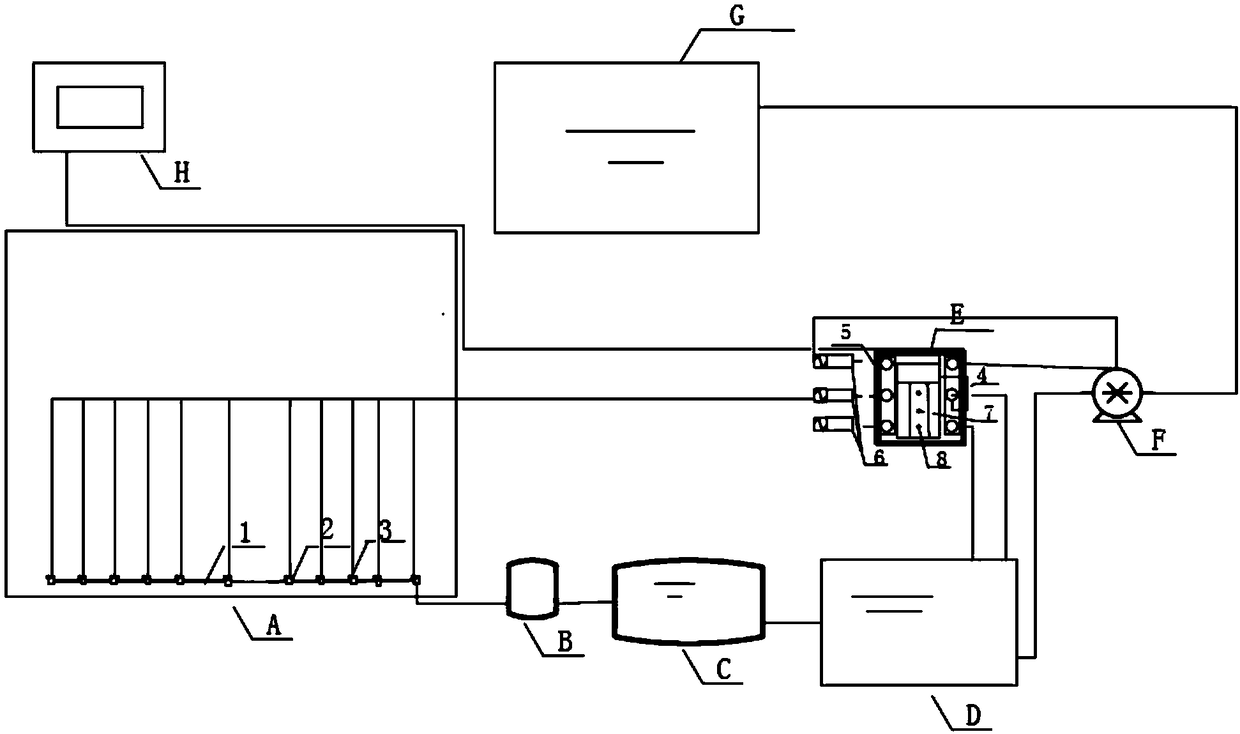

Utility tunnel circulating type firefighting water system device and method and application thereof

A technology of comprehensive pipe gallery and system device, which is applied in fire rescue and other directions, can solve the problems of inability to apply comprehensive pipe gallery, etc., and achieve the effect of increasing water consumption and action time, strong practical operability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The pipe gallery adopts a water spray system with a design flow rate of 0.39m 3 / s, the design continuous supply time is 0.4h. When simulating a fire, start all the sprinklers in the fire compartment where the fire is located, and monitor the flow of the water system at the most unfavorable point. The design test time is 1h, and the results show that the flow rate of the nozzle at the most unfavorable point of the test is always greater than 0.39m 3 / s, and the water level of the original fire pool or water tank of the water spray system is not lower than the minimum effective water level.

Embodiment 2

[0039] The pipe gallery adopts a high-pressure water mist system with a design flow rate of 0.06m 3 / s, the design continuous supply time is 0.5h. When simulating a fire, start all the sprinklers in the fire compartment where the fire is located, and monitor the flow of the water system at the most unfavorable point. The design test time is 2 hours, and the results show that the flow rate of the nozzle at the most unfavorable point of the test is always greater than 0.06m 3 / s, and the water level of the original fire pool or water tank of the high-pressure water mist system is not lower than the minimum effective water level.

Embodiment 3

[0041] The pipe gallery adopts a medium-pressure fine water mist system with a design flow rate of 0.25m 3 L / s, the design continuous supply time is 0.5h. When simulating a fire, start all the sprinklers in the fire compartment where the fire is located, and monitor the flow of the water system at the most unfavorable point. The design test time is 1h, and the results show that the flow rate of the nozzle at the most unfavorable point of the test is always greater than 0.25m 3 / s, and the water level of the original fire pool or water tank of the medium pressure water mist system is not lower than the minimum effective water level.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com