Aluminum profile production process

A production process and technology of aluminum profiles, applied in spraying devices, devices for coating liquid on the surface, coatings, etc., can solve problems such as unreasonable powder spraying systems, difficulty in sanitation and cleaning of powder supply centers, unkempt workers, etc., to achieve Improve production efficiency and product quality, improve labor productivity, and reduce the number of mold repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0056] Embodiment: The simultaneous extrusion process of the A and B sides of the broken bridge heat-insulating aluminum profile includes the following steps:

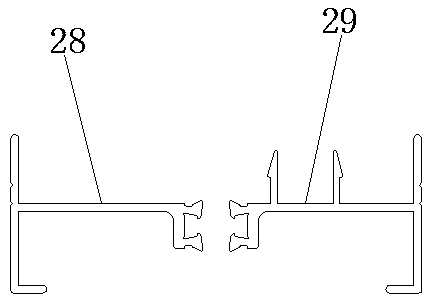

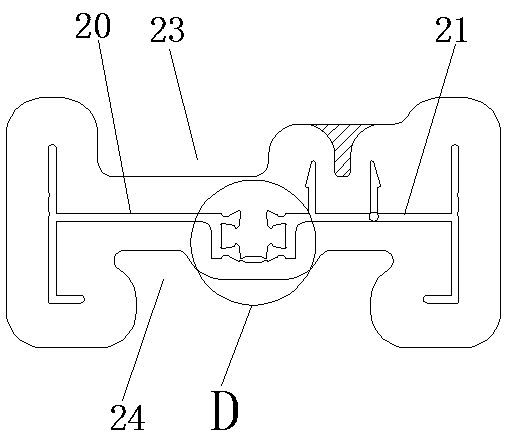

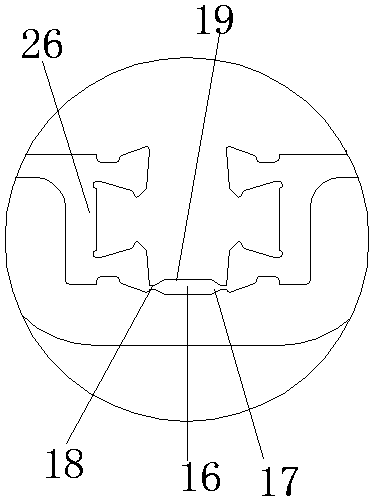

[0057] Step 1. Make the mold: refer to the attached figure 2 , 3 As shown, the mold is designed and molded according to the structure of the AB surface of the aluminum profile. The A-side structure molding cavity 20 and the B-side structure molding cavity 21 of the aluminum profile are processed in the mold, and the A-side structure molding cavity 20 and the B-side structure are formed. The cavities 21 are communicated through the connector cavity 19, and the mold is surface-treated before the upper extruder; the connector cavity 19 includes a square cavity 16 in the middle, and a trapezoidal cavity 17 connected to both sides of the square cavity 16. And two square cavities 18 communicated with the two trapezoidal cavities 17 respectively, the two trapezoidal cavities 17 are symmetrically arranged on both sides of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com