Method for CO2 blowing hardening of casting water glass sand

A technology of water glass sand and water glass, which is applied in casting and molding equipment, molds, and mold components, etc., can solve the problems of reduced mechanical properties of molds and cores, over-blowing defects, and poor core collapsibility. The effect of reducing gas volume, improving working conditions, and low gas production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

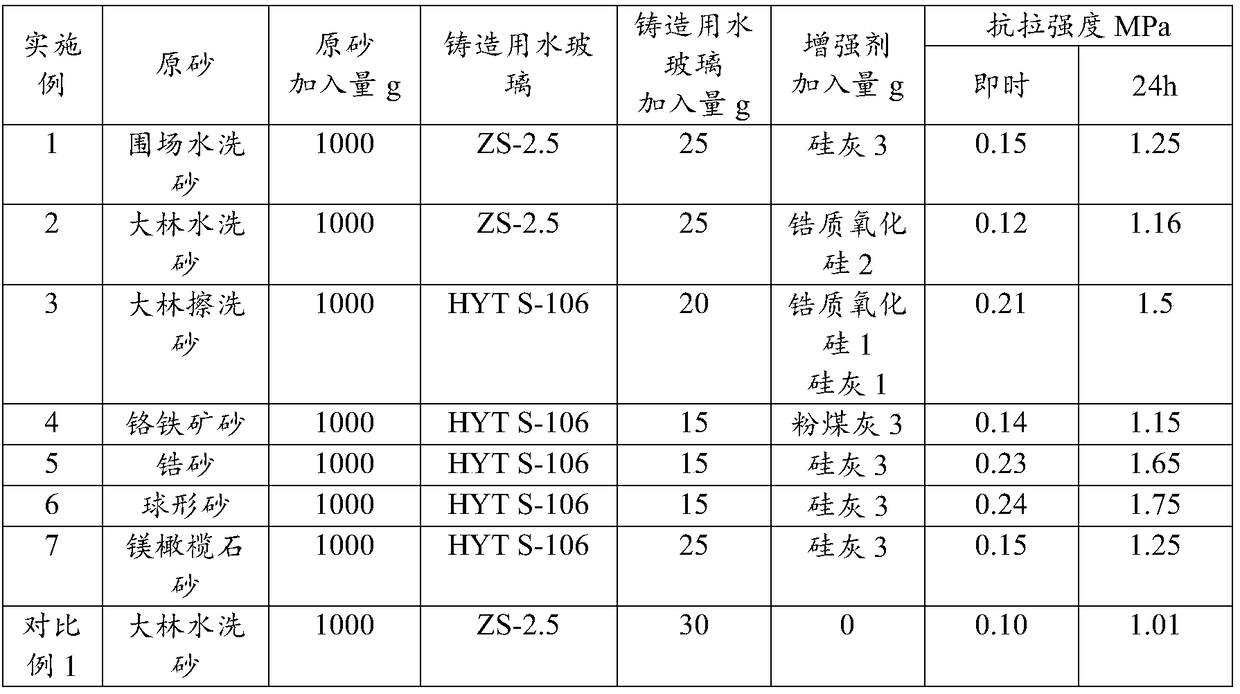

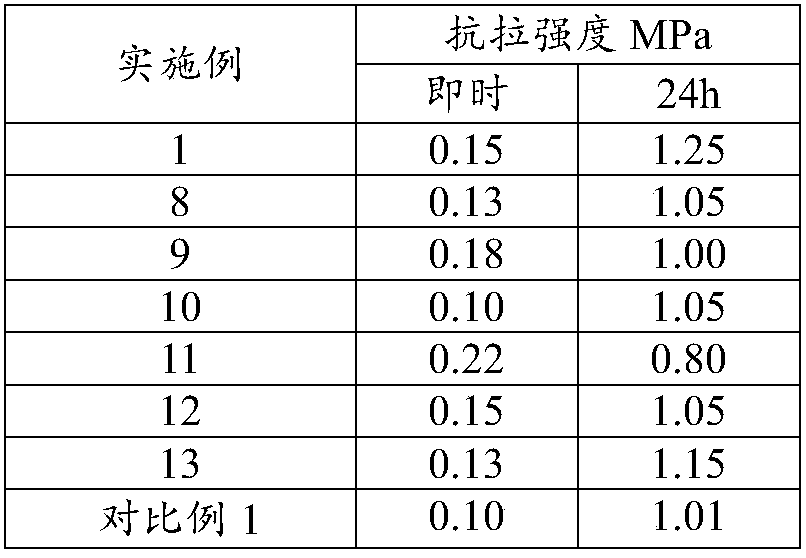

Examples

Embodiment 1

[0038] The sealing box is ¢240mm×240mm, and the sealing cylinder is used. The vacuum pump is a 2XZ4 rotary vane vacuum pump. The core-making sand mixture is manually filled into the standard "8" type mold for compaction.

[0039] Proportion of core-making mixture: Dalin washed sand 1000g, ZS-2.5 modulus 2.4 foundry water glass 25g, silica fume 3g, add SHY blade type core sand mixer and mix well, fill the core-making sand mixture into the standard "8" "Type samples, manually compacted, scraped, 10 samples per batch, put into the sealed cylinder; start the vacuum pump, when the pressure in the sealed cylinder reaches 5Kpa, turn off the vacuum pump, open the CO 2 gas valve, the CO 2 The gas is passed into the sealed cylinder, and when the pressure in the sealed cylinder reaches 30Kpa, the CO2 is closed. 2 Air valve, hold for 20s, open the air valve, let the air quickly enter the sealing cylinder, the sealing cylinder returns to normal pressure, close the air valve; start the vac...

Embodiment 2

[0041] The sealing box is ¢240mm×240mm, and the sealing cylinder is used. The vacuum pump is a 2XZ4 rotary vane vacuum pump. The core-making sand mixture is manually filled into the standard "8" type mold for compaction.

[0042] Proportion of core-making mixture: standard sand 1000g, ZS-2.5 casting water glass 25g, zirconium silica 2g, mix with SHY blade type core sand mixer, fill the core-making mixture into the standard "8" type test Samples are manually tightened and scraped flat, and 10 samples are made in each batch, and put into the sealed cylinder; start the vacuum pump, and when the pressure in the sealed cylinder reaches 8Kpa, turn off the vacuum pump and turn on the CO 2 gas valve, the CO 2 The gas is passed into the sealed cylinder, and when the pressure in the sealed cylinder reaches 0.03Kpa, the CO2 is closed.2 Air valve, hold for 25s, open the air valve, let the air quickly enter the sealing cylinder, the sealing cylinder returns to normal pressure, close the ai...

Embodiment 3

[0044] The sealing box is ¢240mm×240mm, and the sealing cylinder is used. The vacuum pump is a 2XZ4 rotary vane vacuum pump. The core-making sand mixture is manually filled into the standard "8" type mold for compaction.

[0045] Proportion of core-making mixture: standard sand 1000g, HYT-S-106 casting water glass 20g, silica fume 1g, zirconium silica 1g, mix with a laboratory blade sand mixer, and fill the core-making sand mixture into the standard "8" type samples, manually compacted, scraped, 10 samples per batch, put into the sealed cylinder; start the vacuum pump, when the pressure in the sealed cylinder reaches 0.009Mpa, turn off the vacuum pump and turn on the CO 2 gas valve, the CO 2 The gas is passed into the sealed cylinder, and when the pressure in the sealed cylinder reaches 0.03Mpa, the CO2 is closed. 2 Air valve, hold for 25s, open the air valve, let the air quickly enter the sealing cylinder, the sealing cylinder returns to normal pressure, close the air valve;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com