Preparation method for outdoor phenolic resin glue used for bamboo laminated wood

A technology of phenolic resin glue and laminated wood, which is applied in the directions of adhesives, aldehyde/ketone condensation polymer adhesives, adhesive types, etc. The problem of large cross-linking degree of glue molecules, etc., can enhance the permeability of glue, prevent moisture absorption and expansion, and improve the curing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

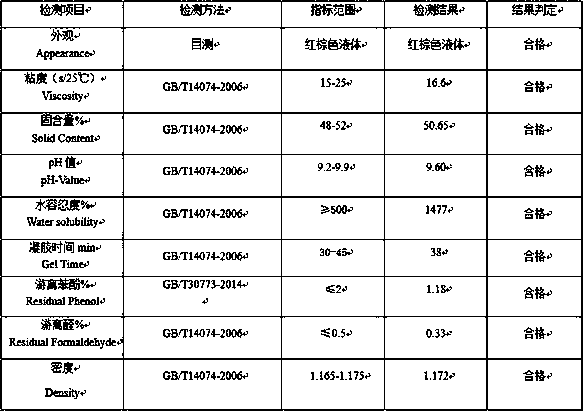

Image

Examples

Embodiment 1

[0039] A preparation method for outdoor phenolic resin glue used for bamboo-wood glulam, comprising the following steps:

[0040] (1) According to parts by mass, prepare 1000 parts of phenol, 1500 parts of formaldehyde, 75 parts of sodium hydroxide, 40 parts of diethylene glycol, 10 parts of epichlorohydrin, 0.5 parts of iron dioxide, 4 parts of melamine and 400 parts of water.

[0041] (2) Mix 75 parts of sodium hydroxide and water at a mass ratio of 1:2 to prepare lye, and put it in a storage tank for later use. The lye is used as a catalyst in gel making, and it is best prepared the day before gel making.

[0042] (3) Stir and mix 1000 parts of phenol, 1500 parts of formaldehyde, 40 parts of diethylene glycol, 10 parts of epichlorohydrin, 0.5 parts of iron dioxide and the rest of water in the reaction kettle for later use.

[0043]Add 18% lye in the resulting mixture, that is, add about 1 / 5th of the above-mentioned lye, because the reaction is exothermic, the present inven...

Embodiment 2

[0055] A preparation method for outdoor phenolic resin glue used for bamboo-wood glulam, comprising the following steps:

[0056] (1) According to parts by mass, prepare 1000 parts of phenol, 1600 parts of formaldehyde, 82.5 parts of sodium hydroxide, 45 parts of diethylene glycol, 15 parts of epichlorohydrin, 0.8 parts of iron dioxide, 5 parts of melamine and 400 parts of water.

[0057] (2) Mix 82.5 parts of sodium hydroxide and water at a mass ratio of 1:3 to prepare lye, and put it in a storage tank for later use. The lye is used as a catalyst in gel making, and it is best prepared the day before gel making.

[0058] (3) Stir and mix 1000 parts of phenol, 1600 parts of formaldehyde, 45 parts of diethylene glycol, 15 parts of epichlorohydrin, 0.8 parts of iron dioxide and the rest of water in the reactor and set aside.

[0059] Add 20% lye to the resulting mixture, that is, add one-fifth of the above-mentioned lye, because the reaction is exothermic, the present invention ...

Embodiment 3

[0070] A preparation method for outdoor phenolic resin glue used for bamboo-wood glulam, comprising the following steps:

[0071] (1) According to parts by mass, prepare 1000 parts of phenol, 1700 parts of formaldehyde, 90 parts of sodium hydroxide, 50 parts of diethylene glycol, 20 parts of epichlorohydrin, 1 part of iron dioxide, 5 parts of melamine and 400 parts of water.

[0072] (2) Mix 90 parts of sodium hydroxide and water at a mass ratio of 1:4 to prepare lye, and put it in a storage tank for later use. The lye is used as a catalyst in gel making, and it is best prepared the day before gel making.

[0073] (3) Stir and mix 1000 parts of phenol, 1700 parts of formaldehyde, 50 parts of diethylene glycol, 20 parts of epichlorohydrin, 1 part of iron dioxide and the rest of water in the reaction kettle for later use.

[0074] Add 22% lye to the resulting mixture, that is, add about 1 / 5 of the above-mentioned lye, because the reaction is exothermic, the present invention do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com