Method for producing copy paper from waste stainless steel lining paper

A stainless steel, copy paper technology, applied in pulp beating method, pulp beating/refining method, special paper, etc., can solve the problems of high production cost of copy paper, high power consumption for beating, and improve paper evenness and gloss. , The effect of improving fiber uniformity and reducing power consumption of beating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

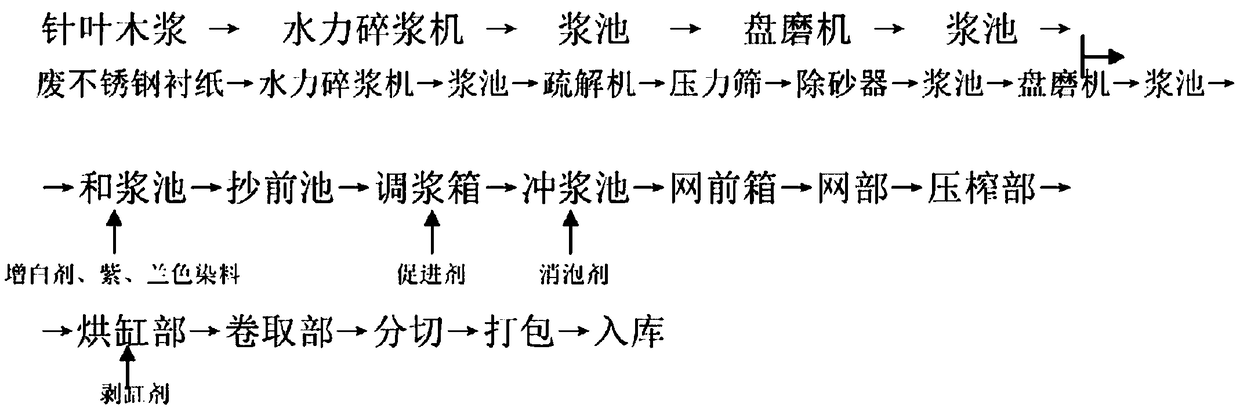

Image

Examples

Embodiment 1

[0022] A method for producing copy paper by using waste stainless steel backing paper, the specific production process: a, coniferous wood pulp is processed through a hydropulper, a pulp tank, a disc refiner, and a pulp tank; b, waste stainless steel backing paper is manually sorted and selected , crushing, dispersing and desandering, screening, desanding pretreatment, and then through hydropulper, pulp tank, descrambler, pressure screen, desander, pulp tank, disc refiner, pulp tank treatment; c, step a The coniferous wood pulp and waste stainless steel liner pulp processed in step b are sent to the blending tank for processing together, and whitening agents, purple and blue dyes are added to the blending tank, and then enter the pre-printing tank for processing, and then enter the pulping tank Pulping box, add accelerator in the pulping box, then enter the punching tank, add defoamer in the punching tank, and then enter the headbox, mesh cloth, pressing section, drying cylinde...

Embodiment 2

[0024] A method for producing copy paper by using waste stainless steel backing paper, the specific production process: a, coniferous wood pulp is processed through a hydropulper, a pulp tank, a disc refiner, and a pulp tank; b, waste stainless steel backing paper is manually sorted and selected , crushing, dispersing and desandering, screening, desanding pretreatment, and then through hydropulper, pulp tank, descrambler, pressure screen, desander, pulp tank, disc refiner, pulp tank treatment; c, step a The coniferous wood pulp and waste stainless steel liner pulp processed in step b are sent to the blending tank for processing together, and whitening agents, purple and blue dyes are added to the blending tank, and then enter the pre-printing tank for processing, and then enter the pulping tank Pulping box, add accelerator in the pulping box, then enter the punching tank, add defoamer in the punching tank, and then enter the headbox, mesh cloth, pressing section, drying cylinde...

Embodiment 3

[0026] A method for producing copy paper by using waste stainless steel backing paper, the specific production process: a, coniferous wood pulp is processed through a hydropulper, a pulp tank, a disc refiner, and a pulp tank; b, waste stainless steel backing paper is manually sorted and selected , crushing, dispersing and desandering, screening, desanding pretreatment, and then through hydropulper, pulp tank, descrambler, pressure screen, desander, pulp tank, disc refiner, pulp tank treatment; c, step a The coniferous wood pulp and waste stainless steel liner pulp processed in step b are sent to the blending tank for processing together, and whitening agents, purple and blue dyes are added to the blending tank, and then enter the pre-printing tank for processing, and then enter the pulping tank Pulping box, add accelerator in the pulping box, then enter the punching tank, add defoamer in the punching tank, and then enter the headbox, mesh cloth, pressing section, drying cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com