Self-power-generation and long-service-life Zn-CoNC zinc-air battery and application thereof

A zinc-air battery, long-life technology, applied in the field of electrochemical energy storage batteries, can solve the problems of the lack of commercialization and application of zinc-air batteries, the difficulty of battery design and electrode technology, and the decline of battery output capacity, so as to increase performance, improve The effect of continuous use time and stability improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

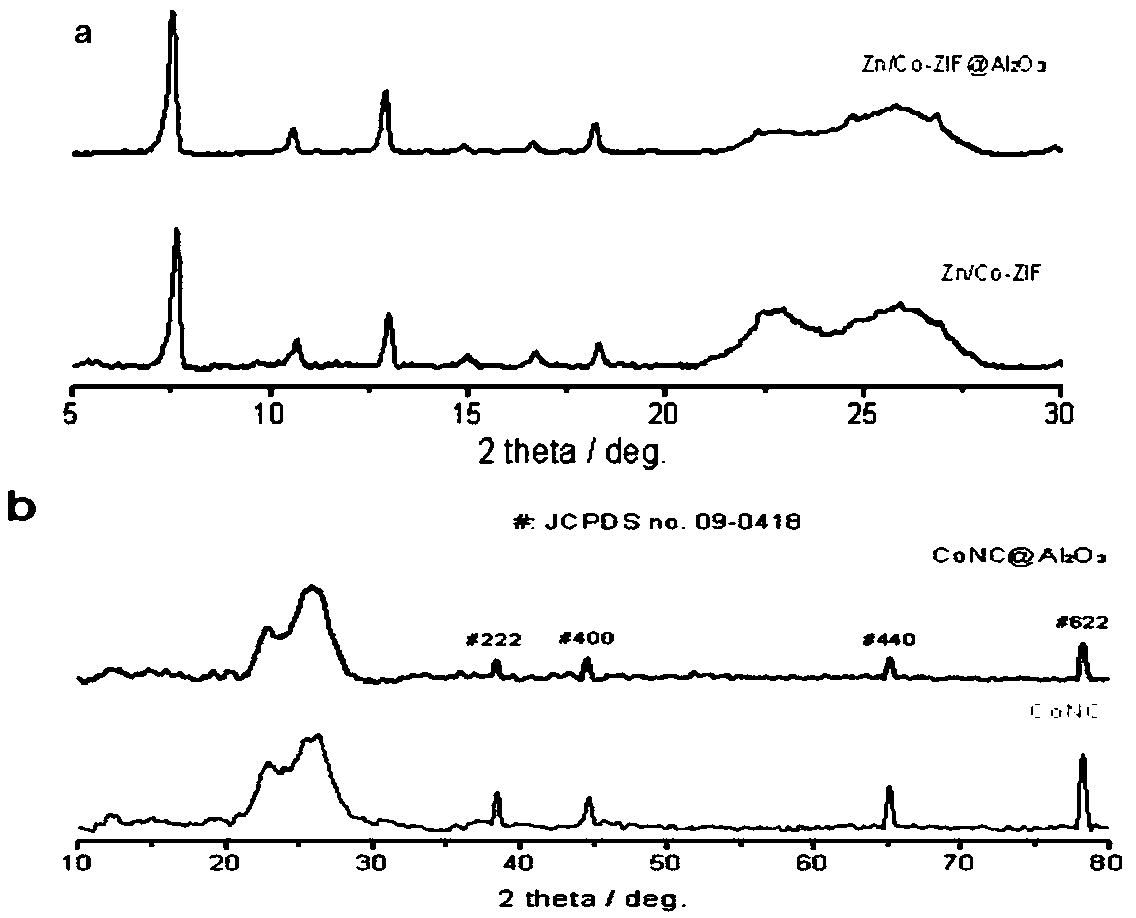

[0027] The synthesis of Zn / Co-ZIF cathode material on flexible carbon cloth was achieved by a hydrothermal method. Using a commercial carbon cloth (2cm×3cm) after ultrasonic treatment in absolute ethanol for 10 minutes as a flexible substrate, add 1mmol zinc nitrate and 4mmol cobalt nitrate to 80mL methanol solution, and add 3.7g methylimidazole to 80mL methanol solution , the two are mixed as a hydrothermal solution, the hydrothermal temperature is 120 ° C, and the time is 2 hours. Al 2 o 3 The layer is obtained by ALD atomic layer deposition, the precursor source is trimethylaluminum (TMA) and water (H 2 O), the temperature is 60°C, the coating thickness: 20cycles.

[0028] Finally Zn / Co-ZIF@Al 2 o 3 in N 2 Annealing at 700°C for 1 to 2 hours under atmosphere to obtain CoNC@Al 2 o 3 nanomaterials;

[0029] The Zn anode material is a thinner commercial zinc sheet, which is polished smooth before use to ensure sufficient contact.

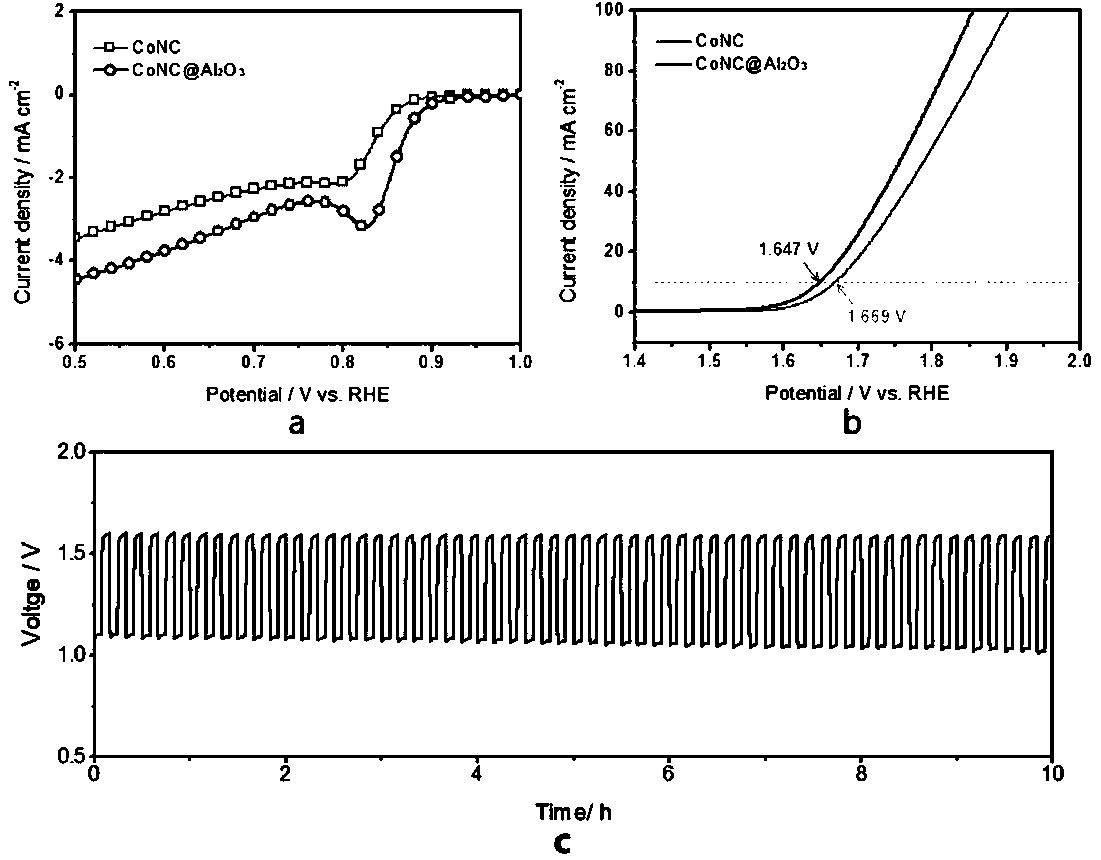

[0030] Performance test: for the pr...

Embodiment 2-10

[0032] The operation process of Examples 2-13 is the same as that of Example 1, except that the time for hydrothermally synthesizing Zn / Co-ZIF, the temperature for ALD deposition of alumina, and the thickness of its coating film.

[0033] The specific hydrothermal synthesis time, synthesis temperature, temperature and coating thickness of aluminum oxide deposited by ALD and the results of each embodiment are listed in Table 1.

[0034] Table 1. Time regulation of hydrothermal synthesis

[0035]

[0036] In summary, the oxygen evolution peak potential of the material properties obtained in Example 13 is 1.647V, and the measured peak potential, the smaller the peak potential (closer to zero), the better its performance, and this condition is the best condition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com