Xenon lamp-pumped liquid cooling laminated repetition frequency sheet amplifier

A liquid cooling and repetition rate technology, applied in laser cooling devices, lasers, phonon exciters, etc., can solve the problems of laser diodes limited by pump sources, difficulty in providing large sizes, small apertures, etc., to reduce spontaneous emission , Suppress parasitic oscillation, improve the effect of operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

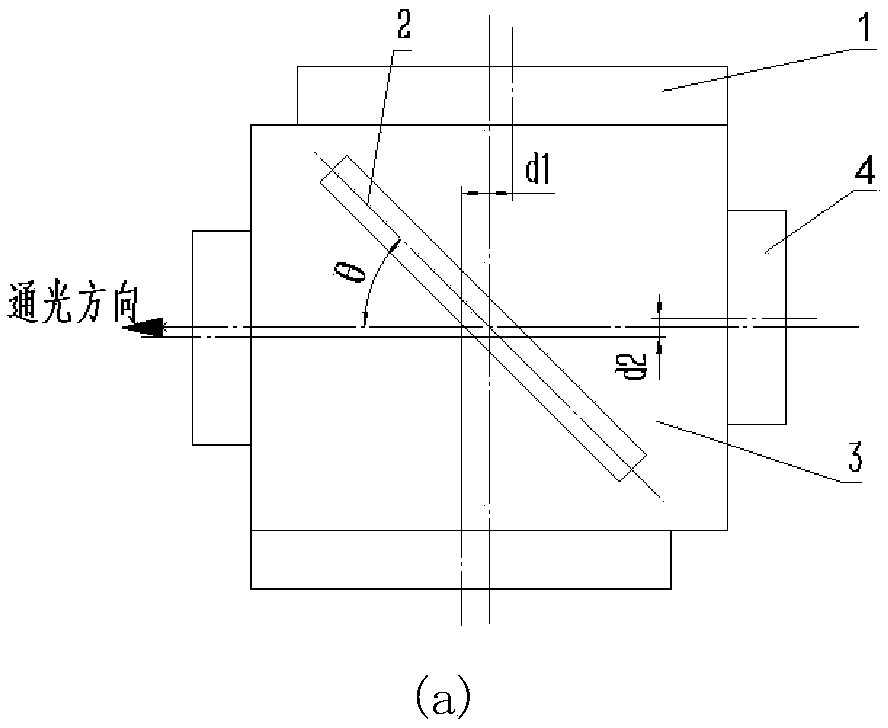

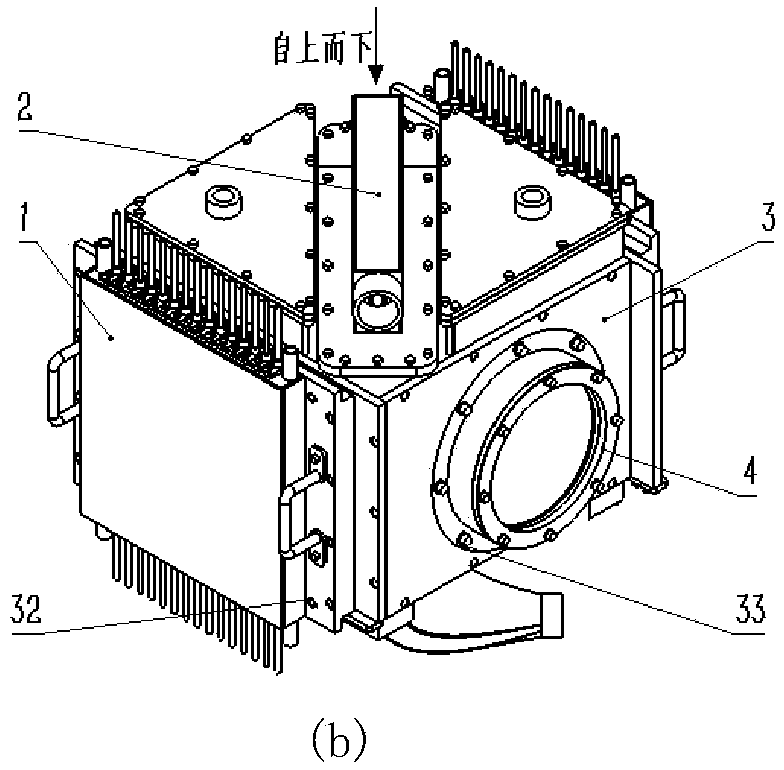

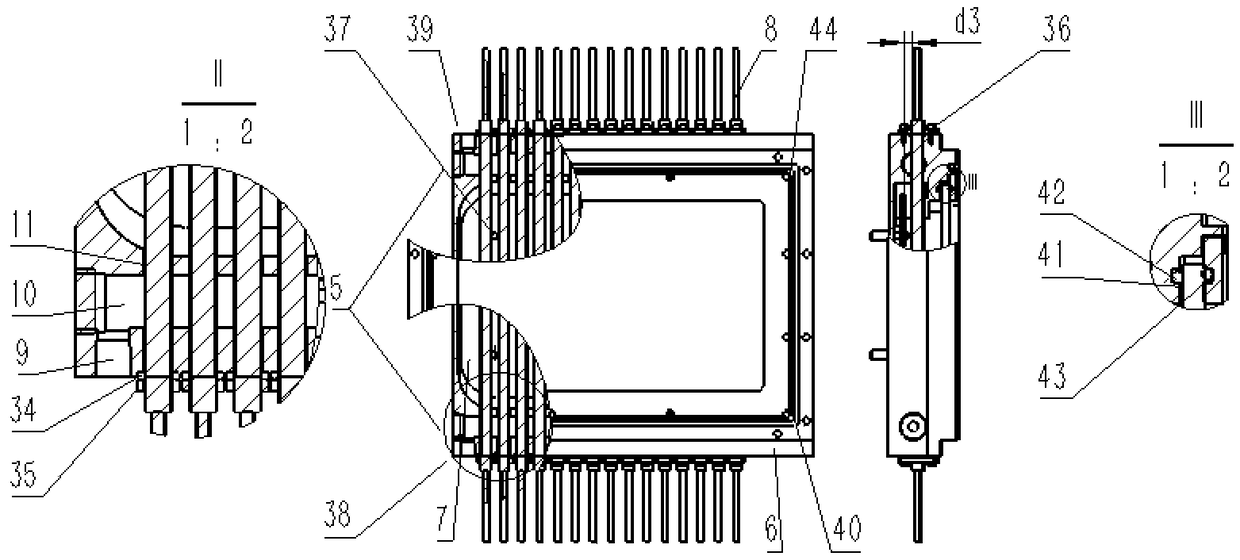

[0030] The stacked repetition rate chip amplifier of the present invention with xenon lamp pumping liquid cooling is shown in Fig. 1- Figure 5 As shown, the stacked repetition rate chip amplifier of the present invention cooled by xenon lamp pumping liquid is composed of a light box assembly 1, a film frame assembly 2, a film cavity assembly 3 and an end mirror assembly 4, and the described film frame assembly 2 is connected to the light-through The direction included angle θ is 45 ° installation, the described film frame assembly 2 is installed in the film chamber assembly 3 from top to bottom, the lower bottom surface of the film frame 13 coincides with the upper surface of the bottom plate of the film chamber 25, and the described light box assembly 1. It is installed on the left and right sides of the cavity assembly 3 by means of screws 33. The displacement distance d1 is 11 mm. The center of the end mirror assembly 4 is installed on the cavity assembly by screws 32 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com