Platinum metal loaded carbon nitride film, and preparation method and application thereof

A technology of carbon nitride and platinum metal, applied in the field of photocatalytic materials, can solve the problems of unsatisfactory photocatalytic performance of carbon nitride, small contact area between catalyst and pollutants, etc., and achieve excellent photocatalytic degradation activity and strong visible light absorption capacity , high catalyst activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

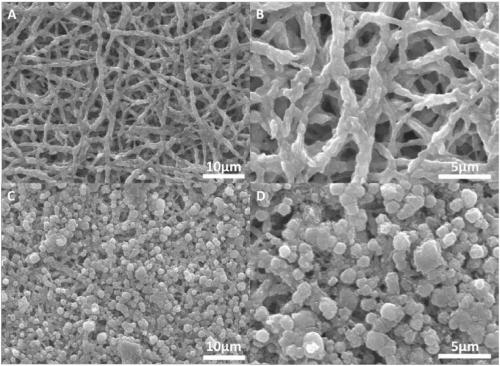

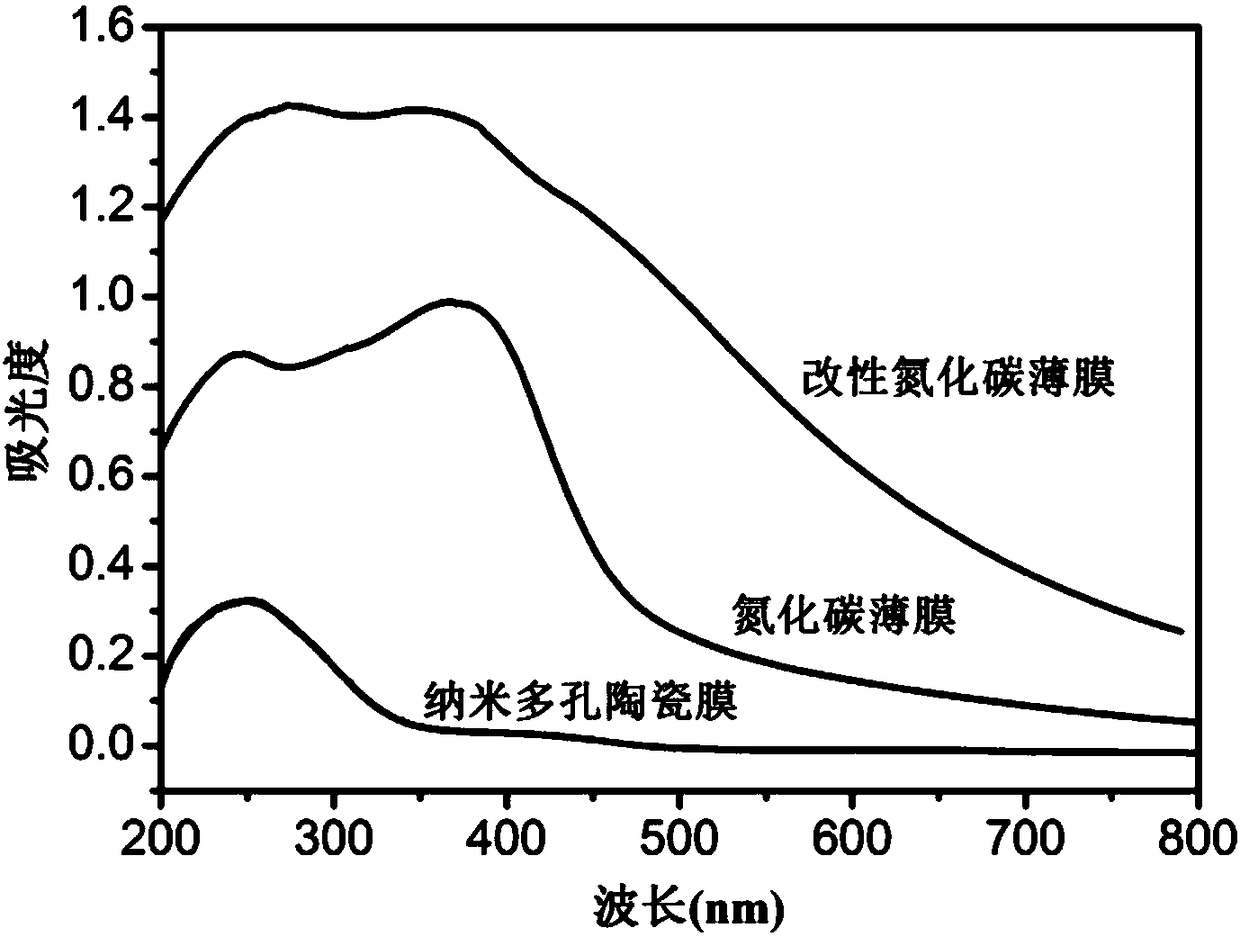

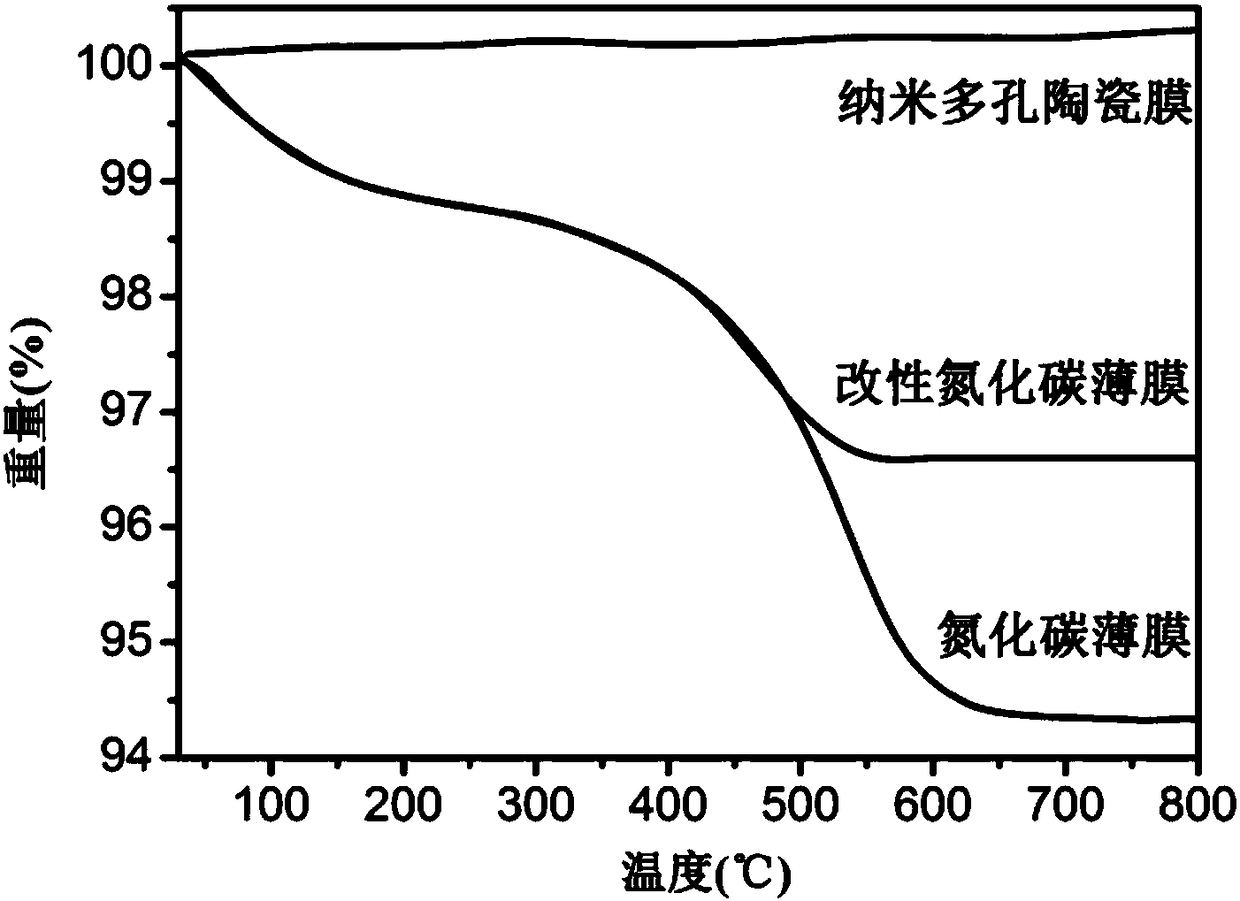

[0039] Put 10g of urea in the bottom of the crucible, place the nanoporous ceramic membrane on the top of the crucible, and calcine in a muffle furnace at a calcination temperature of 550°C, a holding time of 4 hours, and a heating rate of 2.0°C / min. Carbon nitride film of ceramic film; after natural cooling, soak the carbon nitride film in 100 mg / L chloroplatinic acid, take it out after ultrasonication for 5 minutes, and place it under a xenon lamp for 30 minutes, and dry it in an oven at 60 ° C to obtain high Platinum metal-loaded carbon nitride film with high water flux, stronger visible light absorption capacity and excellent photocatalytic degradation activity for aniline sewage. The prepared carbon nitride film was characterized by DRS, XRD, TGA, etc. The results are as follows: Figure 1 ~ Figure 3 shown.

Embodiment 2

[0041] Put 3g of DCDA and 0.07g of DPY in a conical flask, add 15mL of water, heat to 90°C, stir for 1 hour to a clear and transparent solution, transfer it to a petri dish, and dry it in a blast drying oven to obtain a precursor; After being ground into powder, 10 g was weighed and placed at the bottom of the crucible, and the nanoporous ceramic membrane was placed above the crucible, and calcined in a muffle furnace at a calcination temperature of 550°C, a holding time of 4 hours, and a heating rate of 2.0°C / min. A carbon nitride film loaded on a nanoporous ceramic membrane; after natural cooling, it was calcined again to 500°C, kept for 2 hours, and the heating rate was 5°C / min; the obtained carbon nitride film was immersed in 100mg / L of chloroplatinic acid, After ultrasonication for 5 minutes, take it out and irradiate it under a xenon lamp for 30 minutes, and dry it in an oven at 60°C to obtain high water flux, stronger visible light absorption capacity and excellent photo...

Embodiment 3

[0049] Put 10g of thiourea in the bottom of the crucible, place the nanoporous ceramic membrane on the top of the crucible, and calcined in a muffle furnace at a calcination temperature of 400°C, a holding time of 6 hours, and a heating rate of 5.0°C / min. Carbon nitride film of porous ceramic membrane; after natural cooling, immerse the carbon nitride film in 1 mg / L chloroplatinic acid, take it out after ultrasonication for 5 minutes, place it under a xenon lamp for 30 minutes, and dry it in an oven at 60°C to obtain Platinum metal-loaded carbon nitride film with high water flux, stronger visible light absorption capacity and excellent photocatalytic degradation activity for aniline sewage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com