Municipal and metallurgy difficult-to-treat solid waste collaborative resource utilization system

A difficult and resourceful technology, applied in the field of solid waste resource utilization, which can solve the problems of high volatility, limited large-scale application and development, and expensive chlorinating agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

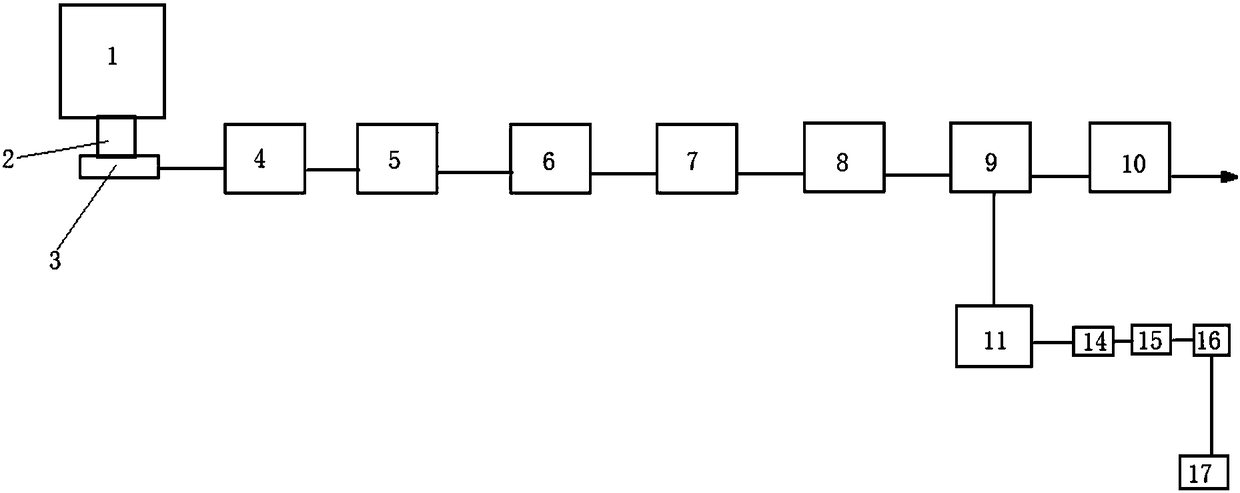

[0128] According to the first embodiment provided by the present invention, a system for collaborative resource utilization of municipal and metallurgical refractory solid waste is provided.

[0129] A system for collaborative resource utilization of municipal and metallurgical refractory solid waste, the system includes:

[0130] 1) Batching device: the batching device includes silo 1;

[0131] 2) Mixing device 4: the discharge port of the silo 1 is connected to the feed port of the mixing device 4 through the first mineral material conveying device G1;

[0132] 3) Moisture mill 5: the discharge port of the mixing device 4 is connected to the feed port of the moist mill 5 through the third mineral material conveying device G3;

[0133] 4) Pelletizer 6: the discharge port of the moistening mill 5 is connected to the feed port of the pelletizer 6 through the fourth mineral material conveying device G4;

[0134] 5) Drying device 7: the discharge port of the pelletizer 6 is con...

Embodiment 1

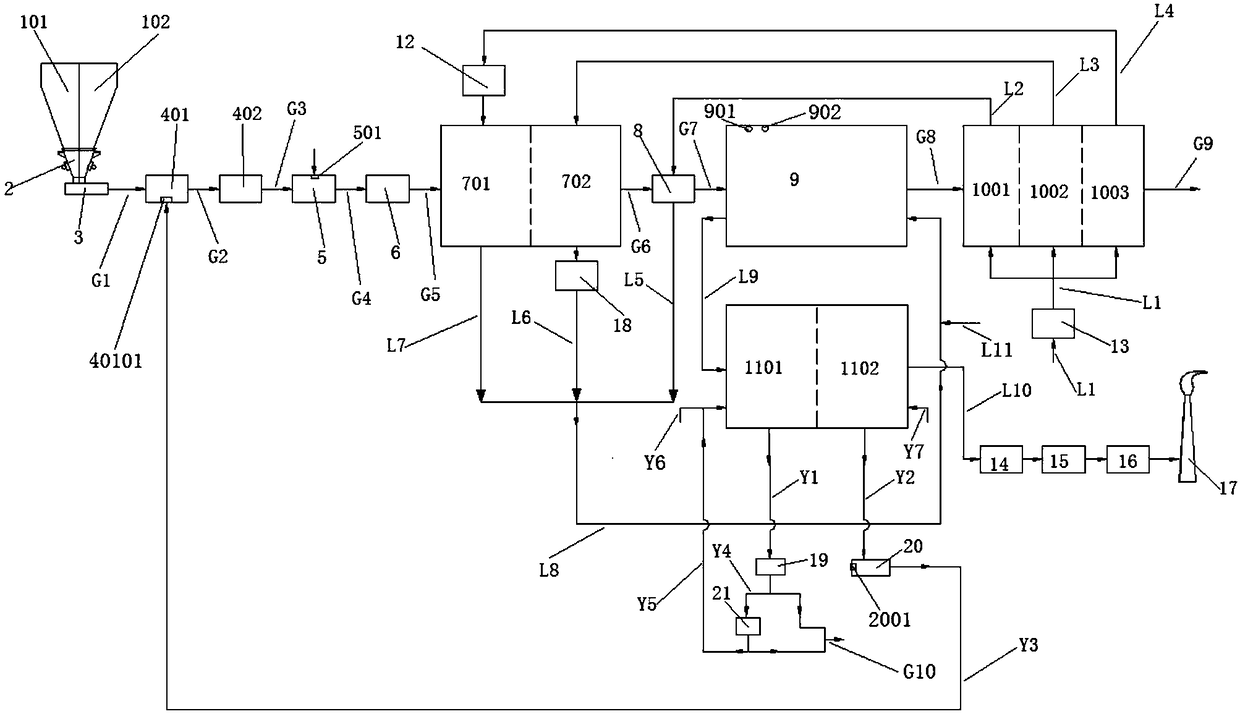

[0205] Such as figure 1 and figure 2 As shown, a system for collaborative resource utilization of municipal and metallurgical refractory solid waste, the system includes:

[0206] 1) Batching device: The batching device includes a silo 1, a vibrating bucket 2, and a feeder 3. The silo 1 includes a garbage incineration fly ash bin 101 and a metallurgical dust bin 102. Below the discharge port of the dust bin 102, the feeder 3 is arranged below the discharge port of the vibrating bucket 2;

[0207] 2) Mixing device 4: the discharge port of the feeder 3 is connected to the feed port of the mixing device 4 through the first mineral material conveying device G1;

[0208] 3) Moisture mill 5: the discharge port of the mixing device 4 is connected to the feed port of the moist mill 5 through the third mineral material conveying device G3;

[0209] 4) Pelletizer 6: the discharge port of the moistening mill 5 is connected to the feed port of the pelletizer 6 through the fourth miner...

Embodiment 2

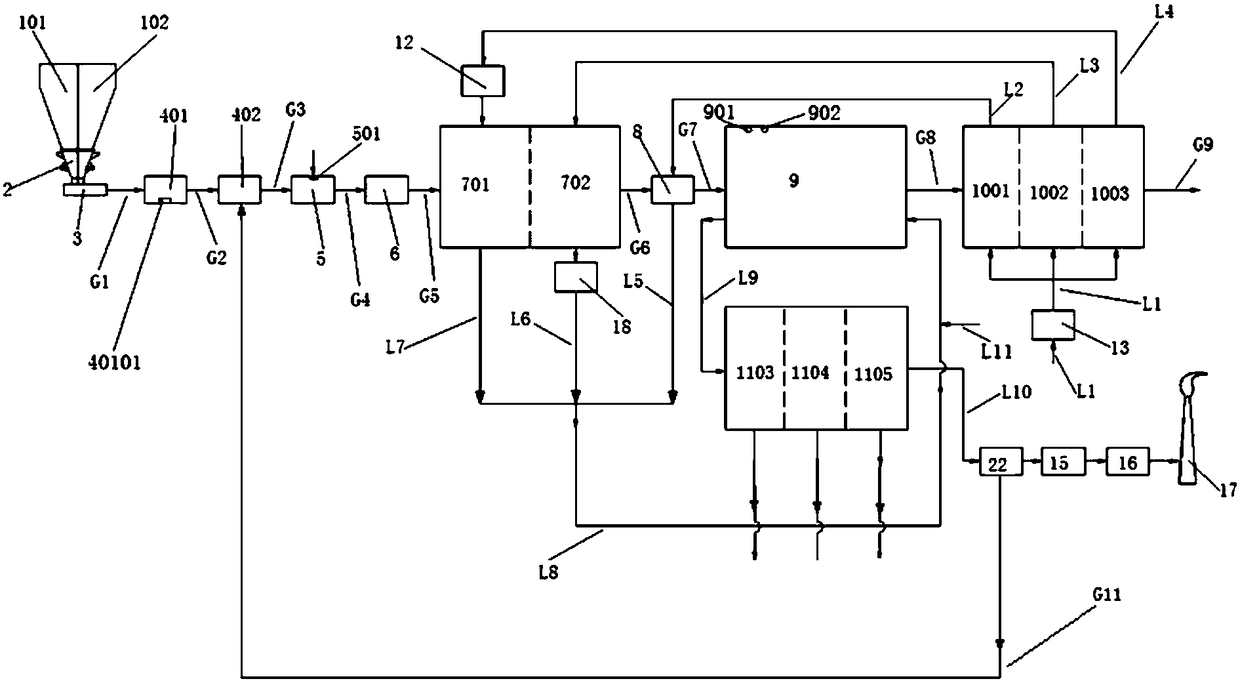

[0215] Repeat Example 1, except that the system further includes: 8) cooling device 10 . The discharge port of the roasting device 9 is connected with the feed port of the cooling device 10 through the eighth mineral material conveying device G8. The discharge port of the cooling device 10 is connected to the blast furnace ironmaking workshop through the ninth mineral material conveying device G9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com