Anti-sticking surface, kitchen knife, pot, scalpel, operation scissors and preparation method

An anti-sticking, knife body technology, applied in surgery, kitchen utensils, parts of surgical instruments, etc., can solve the problems of affecting wound healing, tissue damage, polluting the operating room environment, etc., to reduce the contact area and adsorption force, improve Hydrophobicity, the effect of overcoming thermal adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

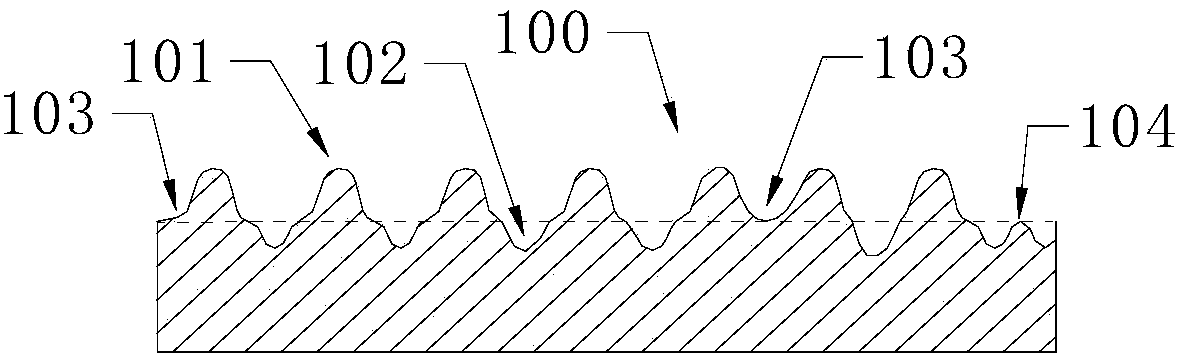

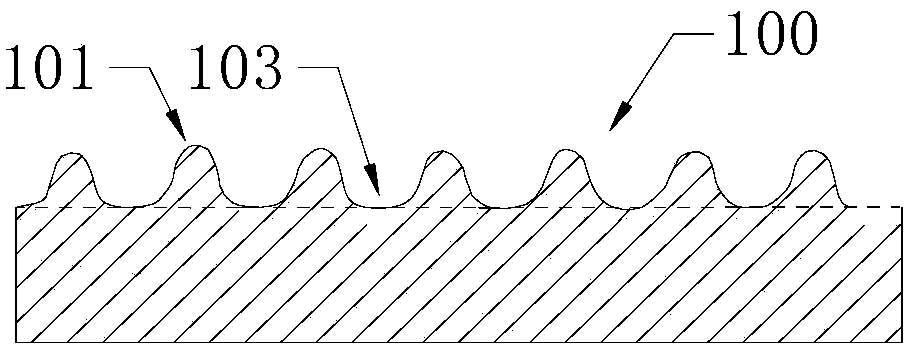

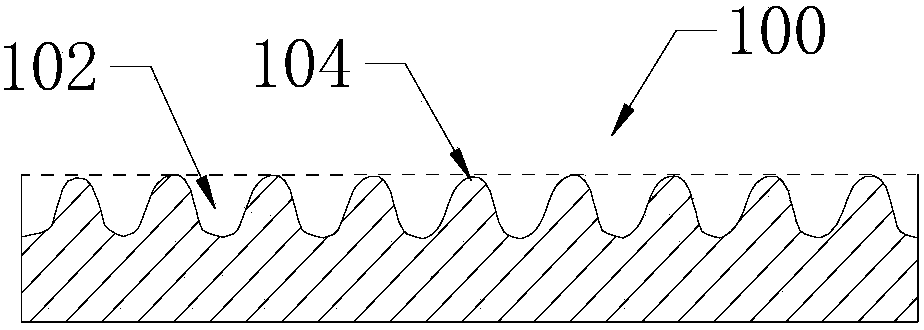

[0067] Preparation of anti-stick surfaces

[0068] This embodiment will introduce a method for preparing an anti-adhesive surface, which can prepare the above-mentioned anti-adhesive surface. The anti-adhesive structure of the anti-adhesive surface is determined by the designed graphics board, and different anti-adhesive structures can be obtained correspondingly to the graphic boards with different graphic design methods. Glue coating machine, baking oven, exposure machine, developing machine and etching machine are used in the process. The model TEL ACT-8 photolithography coating and developing system produced by Caneng Company can be used, which can complete the coating, baking, etc. Baking, exposure and development operations. In this example, an anti-adhesive structure composed of raised parts and dimples is prepared, wherein the raised parts are adjacent to the raised parts, the raised parts are adjacent to the dimples, and the dimples can only be adjacent to the raised...

Embodiment approach

[0089] As an embodiment of the present invention, a non-stick kitchen knife, such as Figure 5 As shown, the anti-stick kitchen knife 200 includes a knife body 210 , a knife handle 220 and an anti-stick surface 100 prepared on the surface of the knife body 210 , and the knife body 210 and the knife handle 220 are fixedly connected. The knife body part 210 includes a knife base part 211 and a knife edge part 212 which are fixedly connected. The knife base part 211 and the knife edge part 212 can be integrally formed or manufactured separately. It should be noted that the knife base 211 and the knife edge 212 can also be made of different materials, and the knife edge 212 is embedded and fixed in the knife base 211 . The knife base 211 is a rectangular thin plate, and the lower side of the knife base 211 is provided with a knife edge 212, as Figure 5 As shown, a large kitchen knife, slicing knife, etc. commonly used for cutting vegetables are formed; in addition, the connectio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com