Rectifying apparatus and method of hexafluoropropylene production cracked gas

A technology of hexafluoropropylene and pyrolysis gas, which is applied in chemical instruments and methods, preparation of halogenated hydrocarbons, organic chemistry, etc., can solve problems such as high risk, many side reactions, and narrow toxicity band, so as to improve the safety level of equipment , the effect of reducing the energy consumption of rectification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

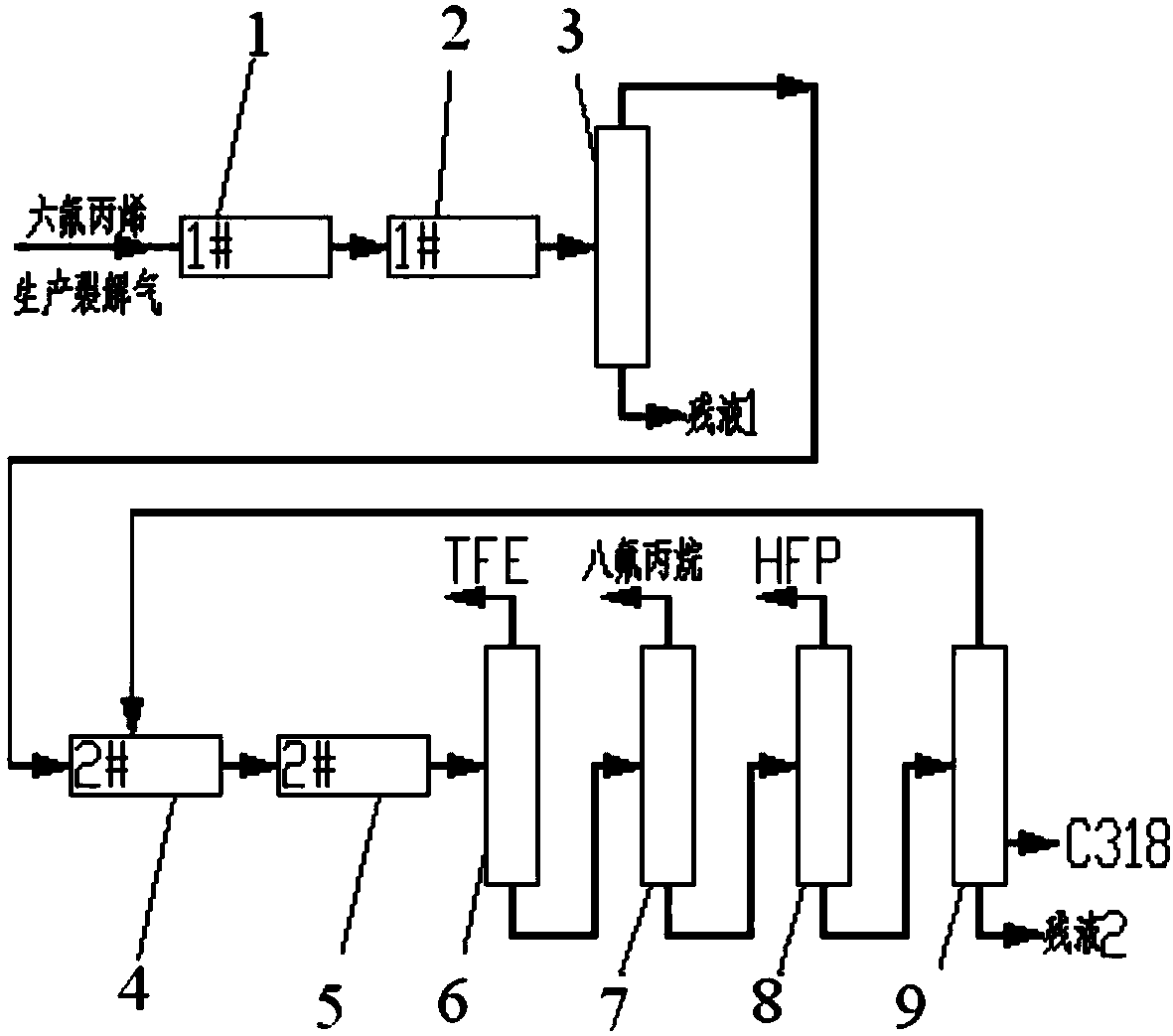

[0034] see figure 1 , a rectification device for producing cracked gas from hexafluoropropylene, comprising a raffinate separation tower 3, a TFE recovery tower 6, a light removal tower 7, a hexafluoropropylene rectification tower 8 and an HFP recovery tower 9;

[0035] The raffinate recovery tower 3 is a rectification tower, and the top of the raffinate recovery tower is connected with the TFE recovery tower 6, and the TFE recovery tower 6 is a rectification tower, and the TFE recovery tower still is connected with the light removal tower 7 Connection, the tower still of the light removal tower is connected with the hexafluoropropylene rectifying tower, and the 8 tower stills of the hexafluoropropylene rectifying tower are connected with the HFP recovery tower 9.

[0036] Hexafluoropropylene production cracking gas pipeline is connected to the middle part of the raffinate separation tower through 1# buffer tank 1 and 1# compressor 2, and the inlet position is the tower body 1...

Embodiment 2

[0039] Adopt the equipment of embodiment 1, a kind of rectification method that hexafluoropropylene produces cracked gas, comprises steps:

[0040] 1) The cracked gas from the production of hexafluoropropylene is rectified by the raffinate separation tower to separate the raffinate containing high-concentration octafluoroisobutene, part of octafluorobutene and a small amount of octafluorocyclobutane. The raffinate enters the subsequent device for detoxification treatment. IM Control does not contain octafluoroisobutene, specifically:

[0041] The sensitive plate is located at the 5th tray above the feed inlet, and the temperature of the sensitive plate is adjusted by adjusting the output flow at the top of the tower, that is, when the temperature of the sensitive plate rises, the output at the top of the tower needs to be reduced; when the temperature of the sensitive plate drops , It is necessary to increase the output; the temperature of the sensitive plate is controlled at ...

Embodiment 3

[0052] Adopt the equipment of embodiment 1, operation step is with embodiment 2, and concrete process parameter is:

[0053] After tetrafluoroethylene and octafluorocyclobutane are mixed, they are thermally cracked, and the cracked gas produced contains TFE37.01%, HFP30.21%, C-318 24.39%, octafluorobutene 4.25%, octafluoroisobutene 4.14% ( Both are mass content);

[0054] 1# buffer tank pressure control 8 ~ 10kPa, compressor outlet pressure control 0.45MPa, 2# buffer tank pressure control 18 ~ 20kPa, compressor outlet pressure control 1.05MPa.

[0055] The pressure of the raffinate separation tower is 0.4MPa, and the temperature is 21-50°C (the temperature at the top of the tower is 21-23°C, and the temperature at the bottom of the tower is 45-50°C); the operating pressure of the 2#TFE recovery tower is 1.2MPa, and the operating temperature is -15-55°C. °C (Temperature at the top of the tower is -15 to -12 °C, temperature at the bottom of the tower is 52 to 55 °C).

[0056] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com