Method for purifying bedaquiline and preparing stable crystal form of bedaquiline

A bedaquiline and crystal form technology, which is applied in the field of purification and preparation of stable crystal forms, can solve the problems of easy agglomeration, difficult to remove, and inconspicuous removal of impurities, and achieves convenient storage, simple operation and controllable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

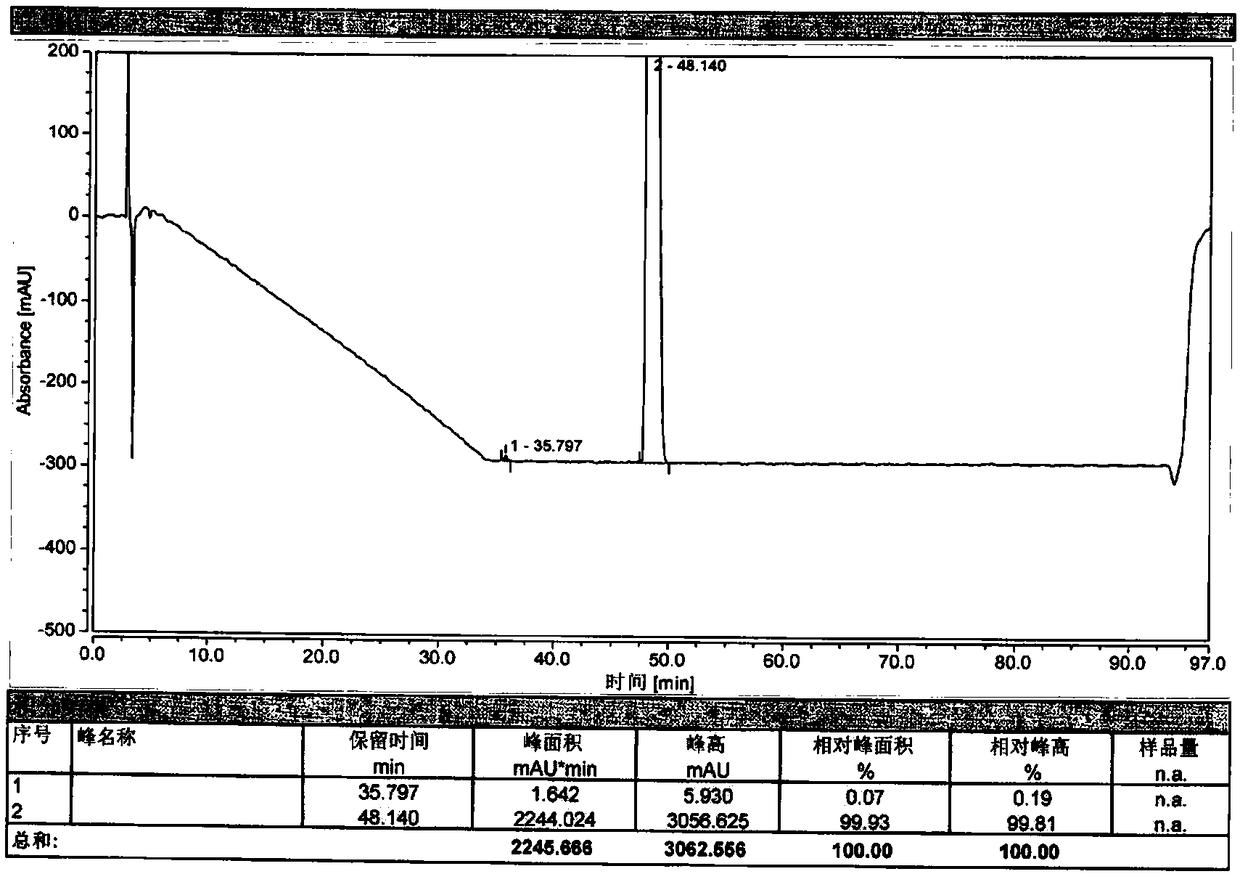

[0028] Add 1200g of bedaquiline-binaphthol phosphate, 12L of toluene, potassium carbonate aqueous solution (dissolve 1.2kg of anhydrous potassium carbonate in about 10.8kg of purified water) into a 30L reactor, heat up to 75-85°C and stir 1 hour, stand still, separate the organic layer while it is hot and transfer it to another 30L reaction kettle, add 10% potassium carbonate aqueous solution (dissolve 1.2kg of anhydrous potassium carbonate in about 10.8kg of purified water with stirring), and heat up to 75-85°C Stir for 15 minutes, let stand for 15 minutes, separate the organic layer, add 0.5 kg of anhydrous sodium sulfate to dry for 3 hours, filter with suction, divide the filtrate into 12 parts by volume and concentrate for purification. Sampling and HPLC purity was 96.1%.

Embodiment 2

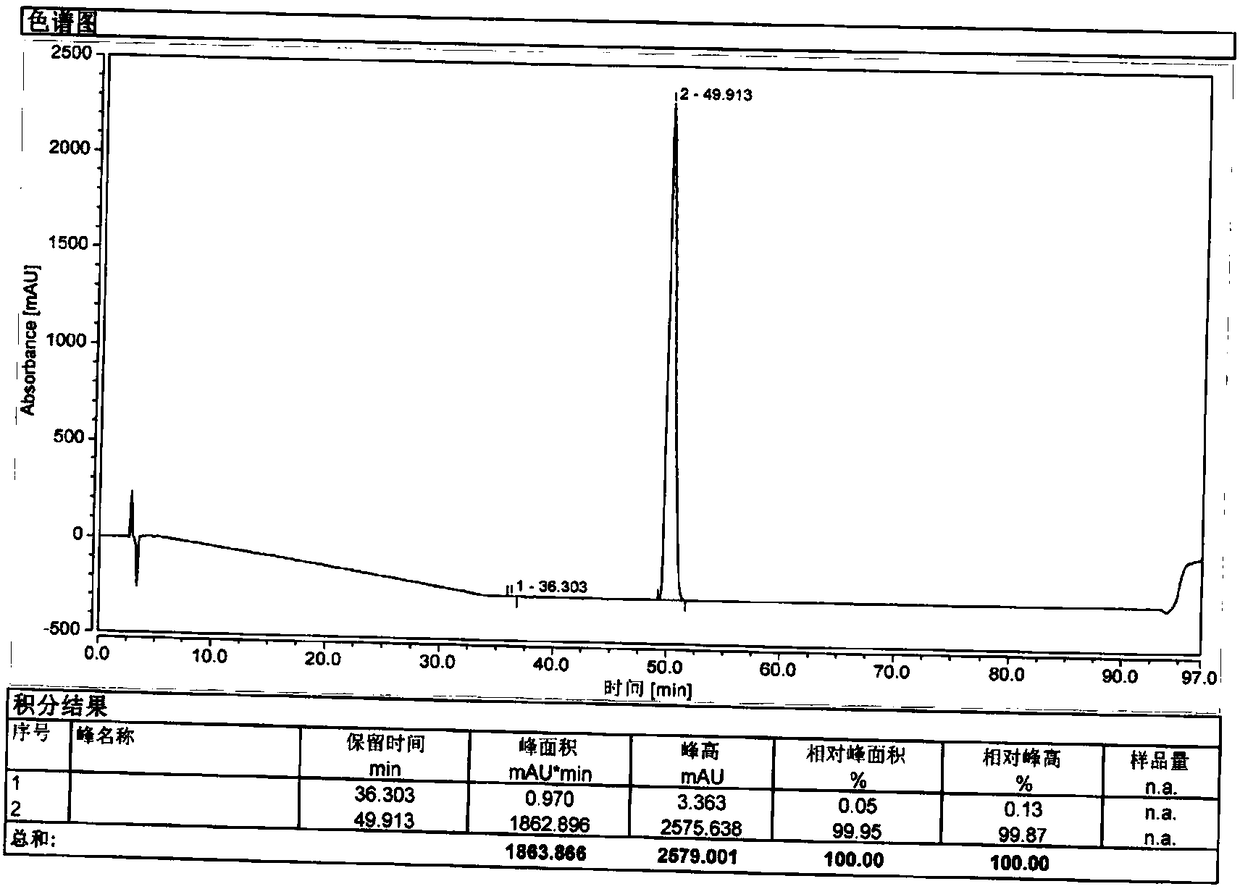

[0030] Take a portion of the concentrated solution obtained in Example 1 (equivalent to 100 g of bedaquiline-binaphthol phosphate ester salt), add 150 ml of acetone, stir and heat up to 50-60° C. until completely dissolved, and control the temperature at 50-60° C. Add 150ml of ethanol dropwise, continue stirring for 15 minutes after dropping, add 150ml of purified water dropwise at a controlled temperature of 50-60°C, cool down to 30-40°C, filter with suction, and air-dry the obtained solid at 50±5°C for 10 hours to obtain 55.8 g white solid is bedaquiline, yield: 90.7%, purity: 99.7%.

Embodiment 3

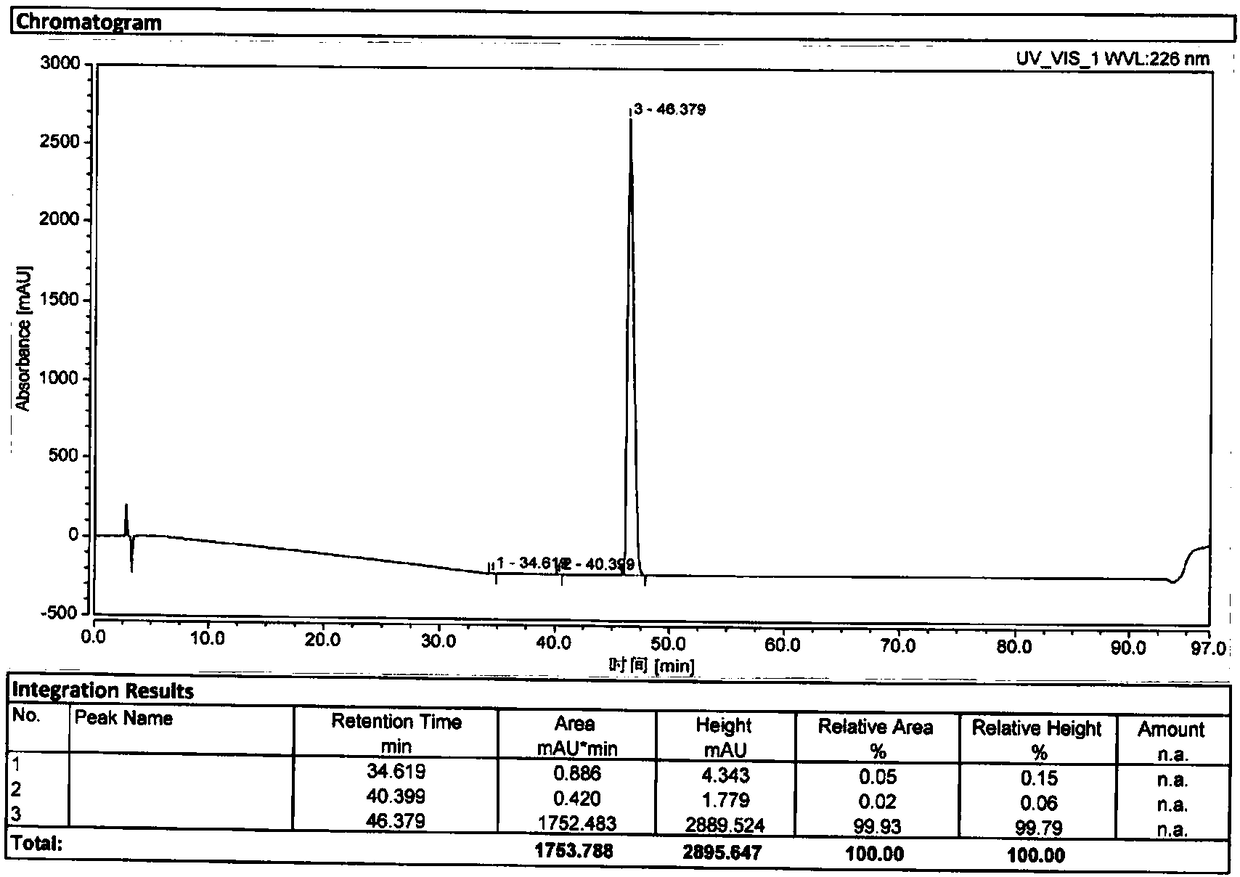

[0032] Get a portion of the concentrated solution obtained in Example 1 (equivalent to 100 g of bedaquiline-binaphthol phosphate ester salt), add 250 ml of acetone, stir and heat up to 50-60° C. until completely dissolved, and control the temperature at 50-60° C. Add 250ml of ethanol dropwise, continue stirring for 15 minutes after dropping, add 250ml of purified water dropwise at a controlled temperature of 50-60°C, cool down to 30-40°C, filter with suction, and air-dry the obtained solid at 50±5°C for 10 hours to obtain 52.9 g white solid is bedaquiline, yield: 86.0%, purity: 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com