Rock color paint

A technology of color paint and micro-powder silica gel, which is applied in the field of rock color paint and can solve the problems of high construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] A kind of rock color paint provided by the invention is prepared in the following way,

[0015] (1) Take by weighing the styrene-acrylic emulsion of 50-60% of the prescription amount, add L-HPMC, phthalate plasticizer and defoamer and stir evenly, and add film-forming aids, and disperse evenly to obtain Mixture 1)

[0016] (2) Mix the prescription amount of titanium dioxide aggregate, color masterbatch, micro-powder silica gel, add wetting agent and remaining styrene-acrylic emulsion, slowly add to the mixed solution in step 1) under stirring state and stir evenly to obtain rock color paint.

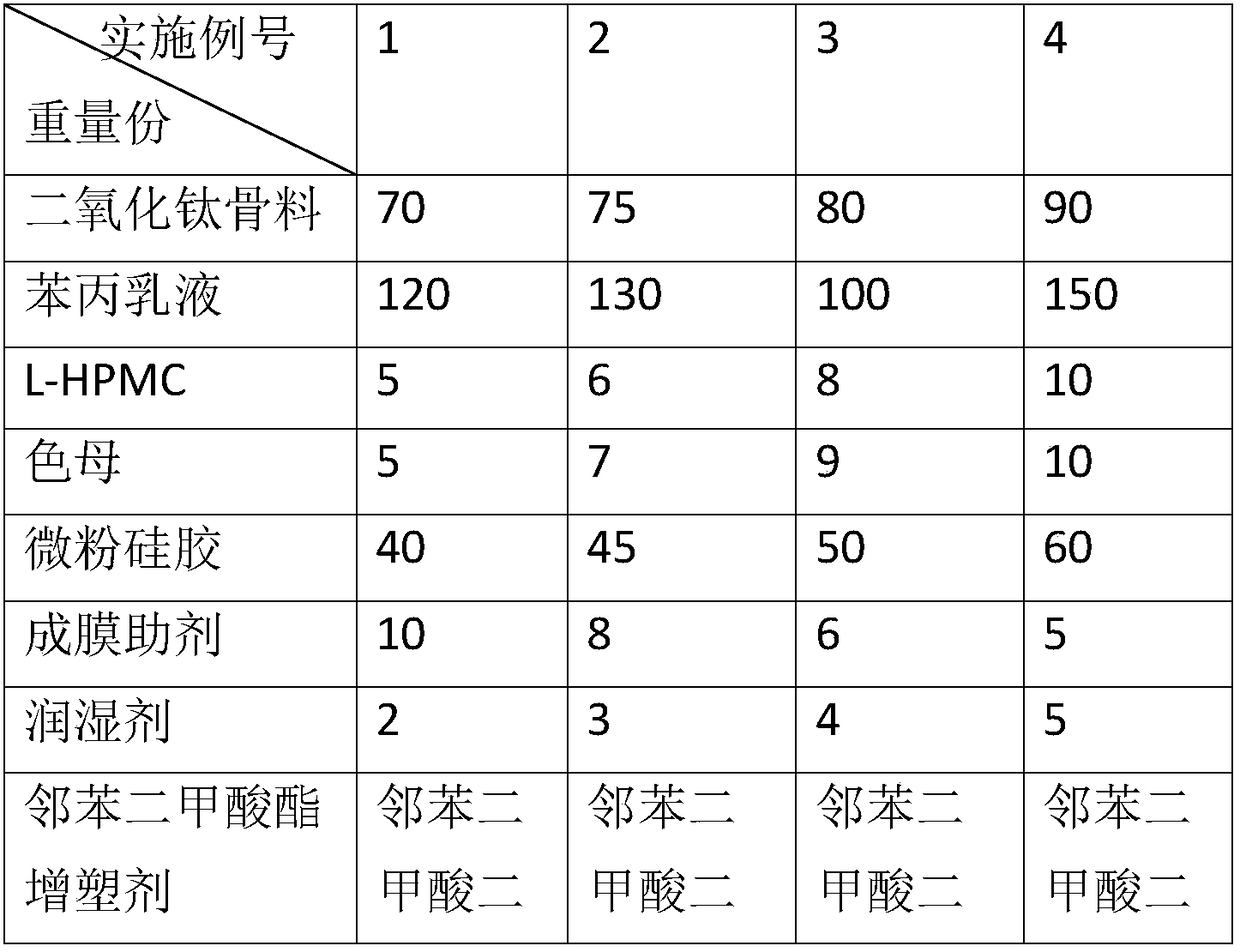

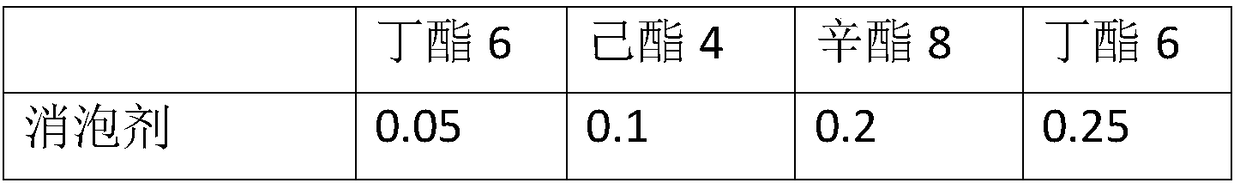

[0017] The formula of embodiment 1-4 sees the following table

[0018]

[0019]

[0020] The particle size range of the micropowdered silica gel is 100-200 μm, the film-forming aid is monoglyceride stearate, the wetting agent is Span-80, and the defoaming agent is methyl silicone oil.

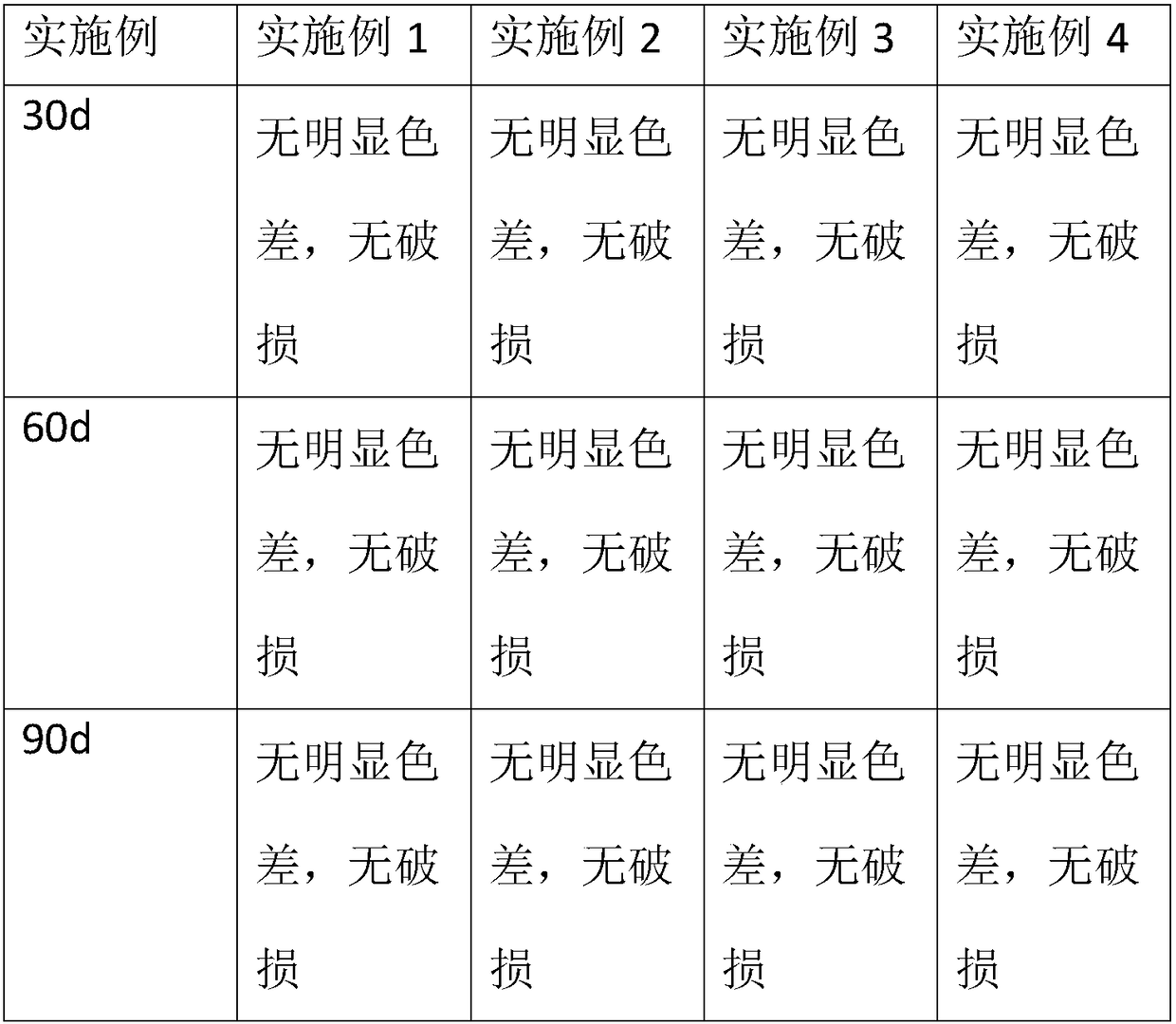

[0021] Ease of Construction Example

[0022] Apply the rock color paint obtained in Ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com