Adhesive composition for encapsulation materials of organic electronic device and adhesive film comprising the same for encapsulation materials of organic electronic device

A bonding composition, organic electronics technology, applied in the direction of polymer adhesive additives, film/sheet without carrier, non-polymer adhesive additives, etc., to achieve excellent moisture resistance and heat resistance, improve life and The effect of durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0194] Embodiment 1: Preparation of adhesive film for packaging materials of organic electronic devices

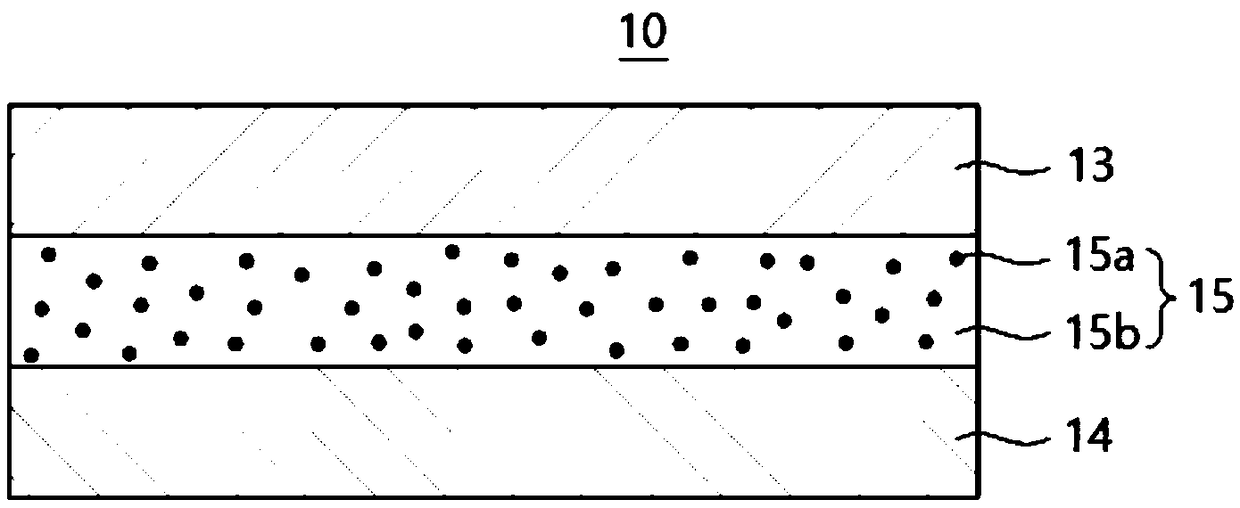

[0195] (1) Formation of the first adhesive layer

[0196] In order to form the first adhesive layer, a random copolymer (first adhesive resin) obtained by copolymerizing ethylene, propylene, and a diene compound and a compound represented by the following chemical formula 1 were mixed in a weight ratio of 1:2.33 ( After the second binder resin) to prepare the first mixed resin, with respect to the first mixed resin of 100 parts by weight, drop into the first tackifier (SU-90 of 80 parts by weight) and 50 parts by weight of The second tackifier (SU-100, Cologne Industries), 11 parts by weight of acrylic acid (M200, Miwon Specialty Chemical) with a weight average molecular weight of 226 as a curing agent, 3 parts by weight of ultraviolet light initiator agent (irgacure TPO, Ciba) and 24 parts by weight of silica with an average particle diameter of 0.5 μm and then stirred. ...

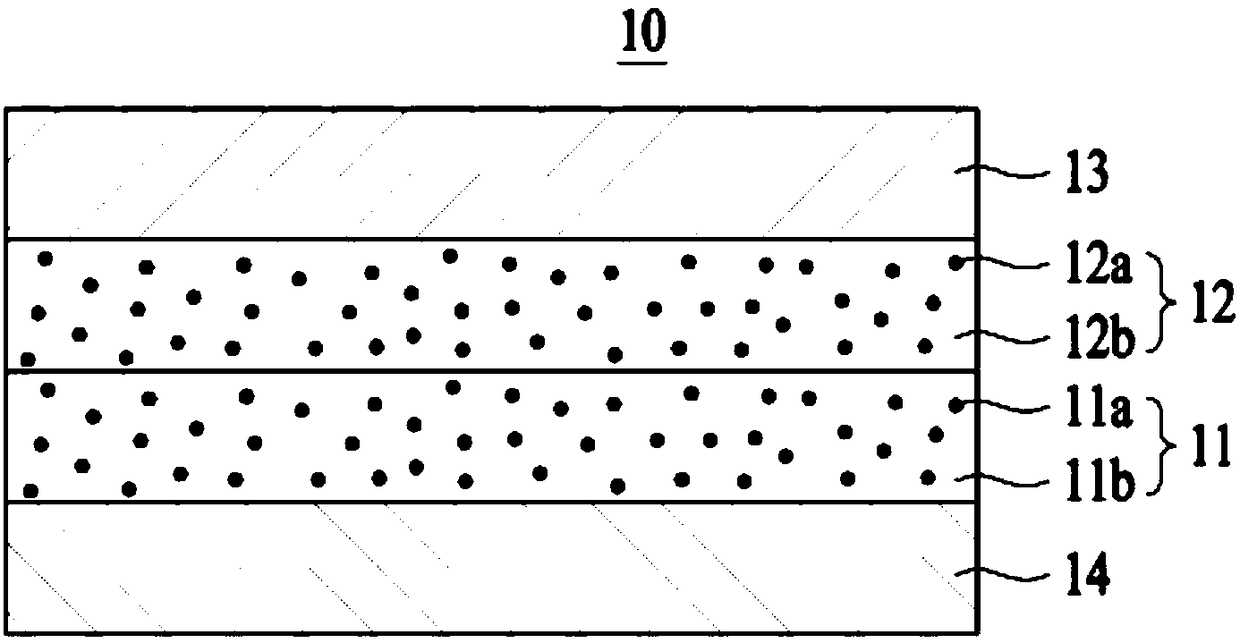

Embodiment 2~22 and comparative example 1~14

[0211]Manufactured in the same manner as in Example 1, but by changing the weight average molecular weight of the first binder resin and the second binder resin, the content of the curing agent, the content of the ultraviolet initiator, etc., the adhesive films shown in Tables 1 to 8 below were produced.

experiment example 1

[0213] The following physical properties were measured for the adhesive films prepared in the Examples and Comparative Examples, as shown in Tables 1 to 8 below.

[0214] 1. Moisture penetration evaluation of adhesive film

[0215] After cutting the test piece with a size of 95mm×95mm, after removing the protective film on the non-alkali glass of 100mm×100mm, align the test piece so that the test piece is located 2.5mm inward from the edge of the four sides of the non-alkali glass, and use heating Roll lamination to 65°C for attachment. After removing the remaining release film in the attached test piece, cover it with another 100mm×100mm non-alkali glass, and use a vacuum laminator to laminate at a temperature of 65°C for one minute to prepare a bonded sample without air bubbles. The length of moisture penetration was observed in units of 1000 hours in a reliability chamber set at 85° C. and a relative humidity of 85% for the bonded sample.

[0216] 2. Evaluation of volume ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com