Fuel cell system and vehicle

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems such as the inability to further improve the insulation resistance of the system, the decline in the insulation performance of fuel cells, and the reduction of ion content in cooling liquids , to achieve the effect of increasing the service life, reducing the burden and reducing the quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

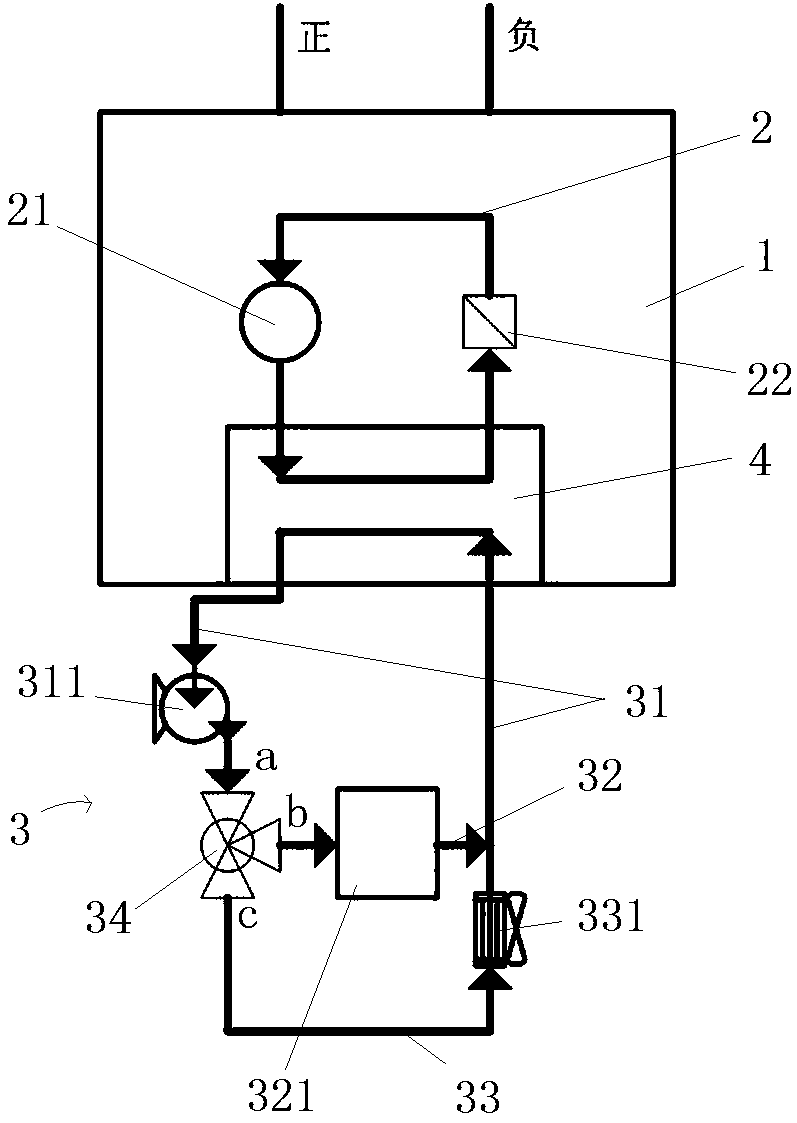

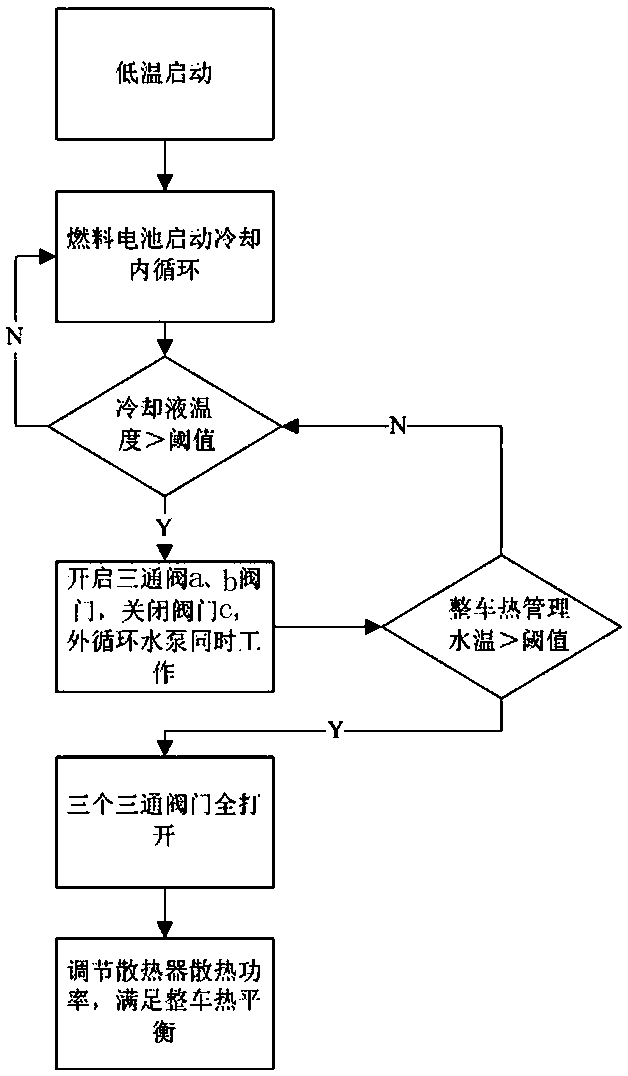

[0028] Specific embodiment 1 of the vehicle of the present invention: the vehicle includes a vehicle body, and the vehicle body is equipped with a vehicle thermal management and a fuel cell system, such as figure 1 As shown, the fuel cell system includes a fuel cell 1. This embodiment refers to a hydrogen fuel cell 1. The fuel cell 1 is a place for hydrogen fuel reaction. After the reaction, heat and water are generated in the hydrogen fuel cell 1, and the water is discharged through the tailpipe . The internal panel of the fuel cell 1 is provided with an internal circulation pipeline 2. The internal circulation pipeline 2 includes a circulation pipeline, an internal circulation water pump 21 and a deionizer 22 arranged on the circulation pipeline. The circulation pipeline is filled with cooling liquid, and the circulation pipeline is also connected to There is a coolant tank for automatically replenishing coolant, and the coolant tank is also located inside the fuel cell 1 . ...

specific Embodiment 2

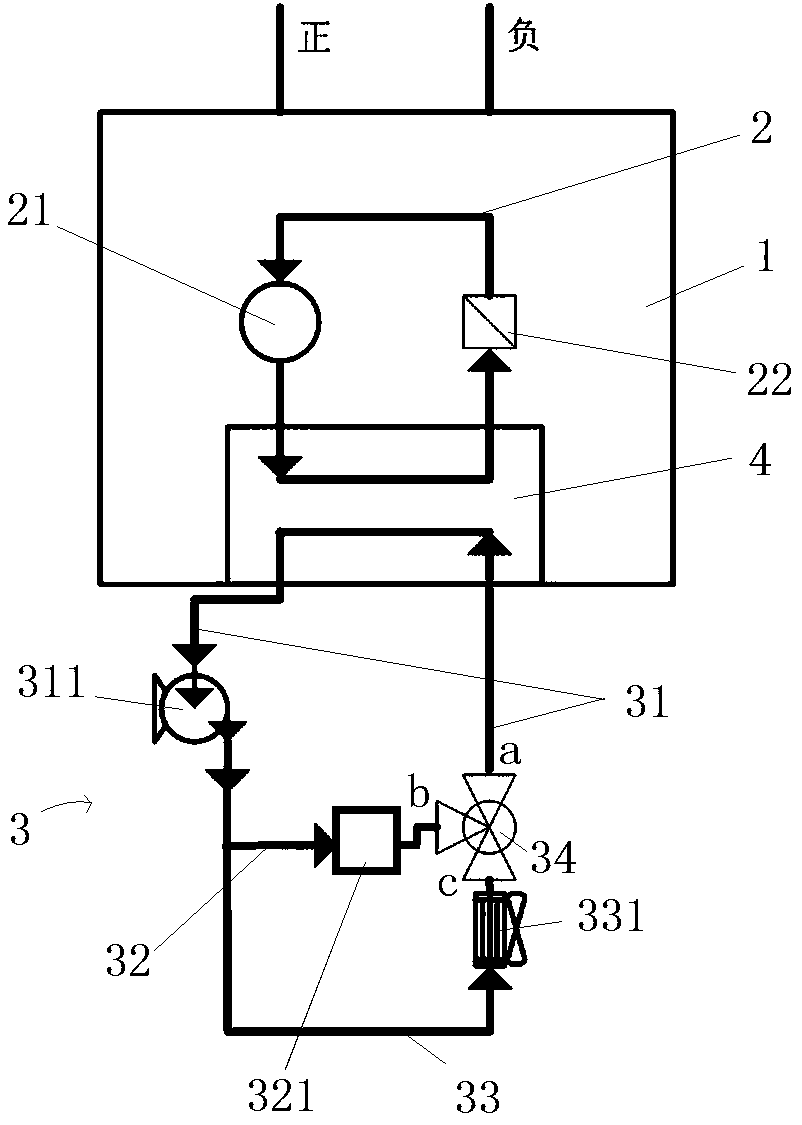

[0031] Specific embodiment 2 of the vehicle of the present invention: the difference between this embodiment and embodiment 1 is that, as image 3 As shown, the three-way valve 34 is set at the intersection of the external circulation pipeline and the right side of the first and second branches, where the control of the main external circulation circuit 31 and the first branch 32 and the second branch 33 can still be realized. On-off purpose.

[0032] In other embodiments: the controller for controlling the on-off of the three-way valve is not limited to the vehicle controller, and the control of the three ports of the three-way valve can also be realized by adding an independent three-way valve controller; the heat exchanger is not limited to Located inside the fuel cell, the integration level is higher when it is located inside the fuel cell, and it is also located outside the fuel cell. At this time, the internal circulation pipeline needs to be led out and coupled with the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com