Organic nutrient soil

A technology of organic nutrition and leaf humus, applied in the soil field, can solve problems such as soil compaction, soil aggregate structure damage, and agricultural plant yield decline, and achieve the effects of reducing safety risks, improving drought resistance, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

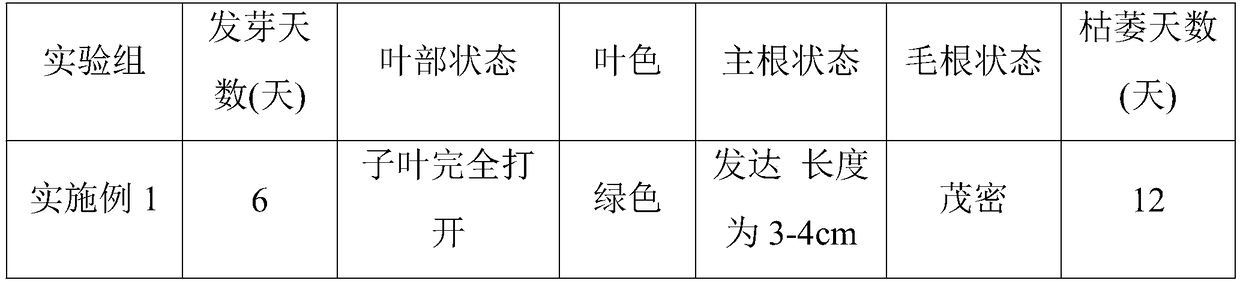

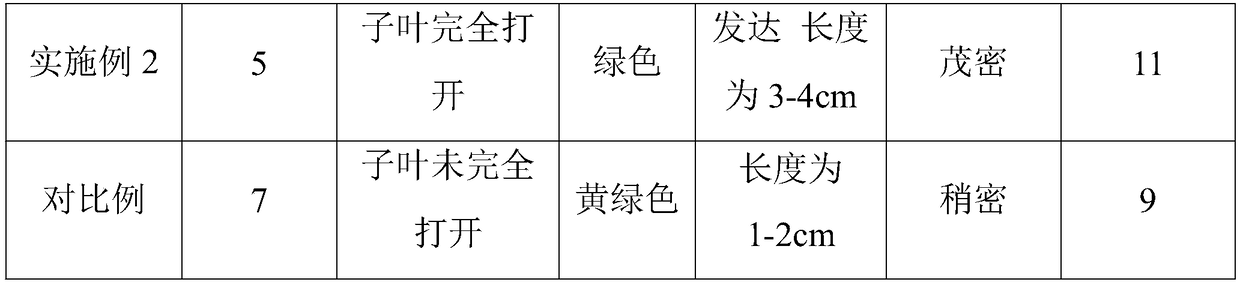

Examples

Embodiment 1

[0019] The present invention proposes a kind of organic nutrient soil, comprises the following components in parts by weight: 24 parts of humus soil, 22 parts of coir peat, 14 parts of nanmu powder, 9 parts of expanded cow dung, 12 parts of straw ashes, phosphate rock powder or 7 parts of superphosphate, 6 parts of traditional Chinese medicine residue, 5 parts of soil water retaining agent, and 1 part of compound microbial agent.

[0020] Described soil water retaining agent is prepared by the following steps:

[0021] (1) Weigh coconut bran, wheat bran, peanut shell and clam shell powder according to the weight ratio of 1:0.7:0.5:0.4:0.3, place them in an oven to dry, crush, pass through a 40-mesh sieve, and obtain baked dry ingredients;

[0022] (2) Place the commercially available superabsorbent resin in an oven to dry, pulverize, and pass through a 60-mesh sieve;

[0023] (3) Mix the drying material in step (1) and the superabsorbent resin in step (2) at a mass ratio of ...

Embodiment 2

[0030] An organic nutrient soil, comprising the following components in parts by weight: 22 parts of leaf humus, 16 parts of coir peat, 17 parts of nanmu powder, 15 parts of expanded cow dung, 13 parts of straw ash, 7 parts of phosphate rock powder or superphosphate 4 parts, 4 parts of traditional Chinese medicine dregs, 4 parts of soil water retaining agent, 2 parts of compound microbial agent.

[0031] Described soil water retaining agent is prepared by the following steps:

[0032] (1) Weigh coconut bran, wheat bran, peanut shell and clam shell powder in a ratio of 1:0.6:0.8:0.45:0.35 by weight, place them in an oven to dry, crush, pass through a 40-mesh sieve, and obtain baked dry ingredients;

[0033] (2) Place the commercially available superabsorbent resin in an oven to dry, pulverize, and pass through a 60-mesh sieve;

[0034] (3) Mix the drying material in step (1) and the superabsorbent resin in step (2) at a mass ratio of 1:1 to obtain mixture A, and mix mixture A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com