Alkaline liquid purification device and method

A purification device and lye technology, which is applied in viscose fiber production and paper making, can solve the problems of difficult cleaning process of plate and frame filter, harsh environment in dismantling plate and frame, waste of lye, etc., so as to save manpower and realize automatic Controllable and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

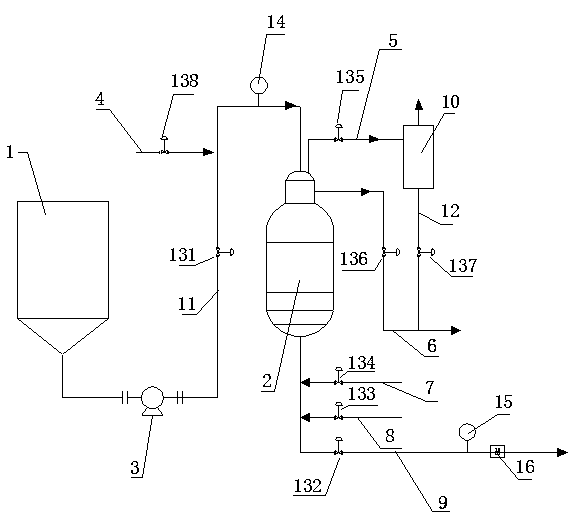

[0027] refer to figure 1 , present embodiment proposes a kind of lye purifying device, comprises raw material lye barrel 1, fluidized bed separator 2, compressed air pipeline I4, waste gas discharge pipeline 5, waste water discharge pipeline 6, soft water pipeline 7, compressed air pipeline II8 and filtrate Output pipeline 9, this purification device is used for the pretreatment operation before the waste caustic liquor enters the nanofiltration system, needs to remove larger solid matter such as fiber, silt, resin in the waste caustic liquor, the booster installed on the pipeline I11 The pressure pump 3 transports the waste lye in the raw material lye barrel 1 to the fluidized bed separator 2 through the pipeline I11 for filtering. The valve I131 for controlling the opening and closing of the pipeline I11 is installed on the pipeline I11, and the pipeline I11 is connected with the compressed air pipeline I4. A valve VIII138 is installed on the compressed air pipeline I4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com