Venturi-type bubble generation device with multiple Venturi structures

A bubble generating device, Venturi-type technology, applied in the direction of gas dissolution, transportation and packaging, mixers, etc., can solve the problem of limited ability to prepare bubbles, and achieve the effect of simple structure, easy cleaning, and strong pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The main content of the present invention is further illustrated below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

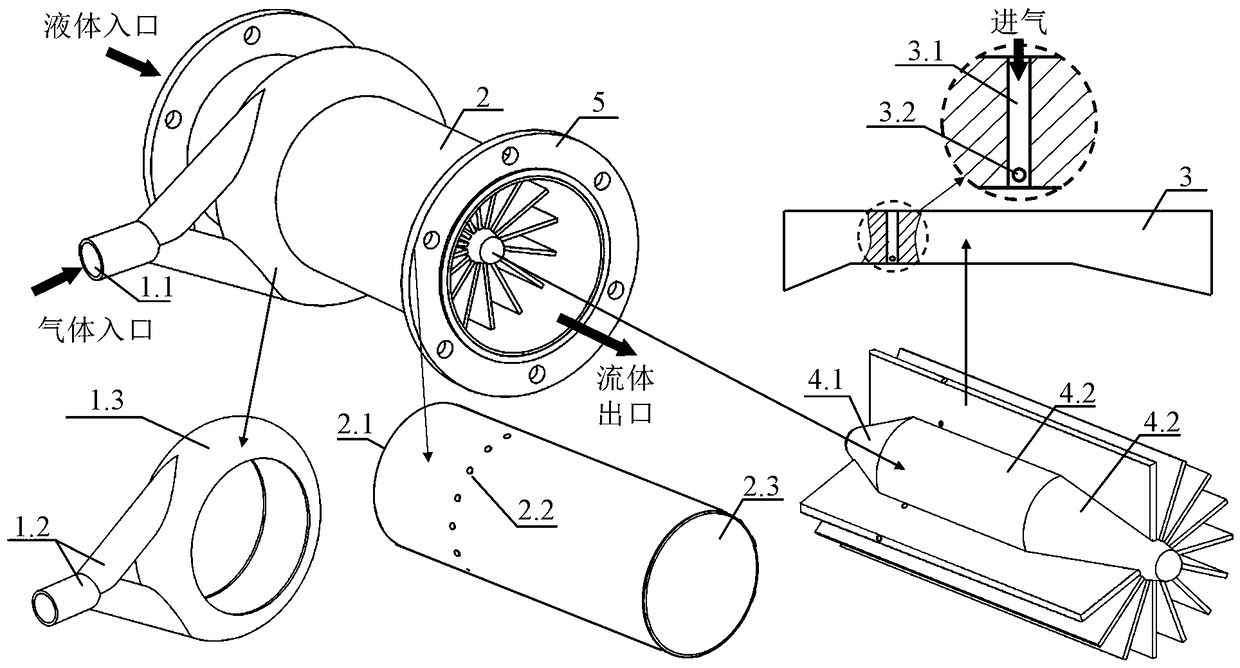

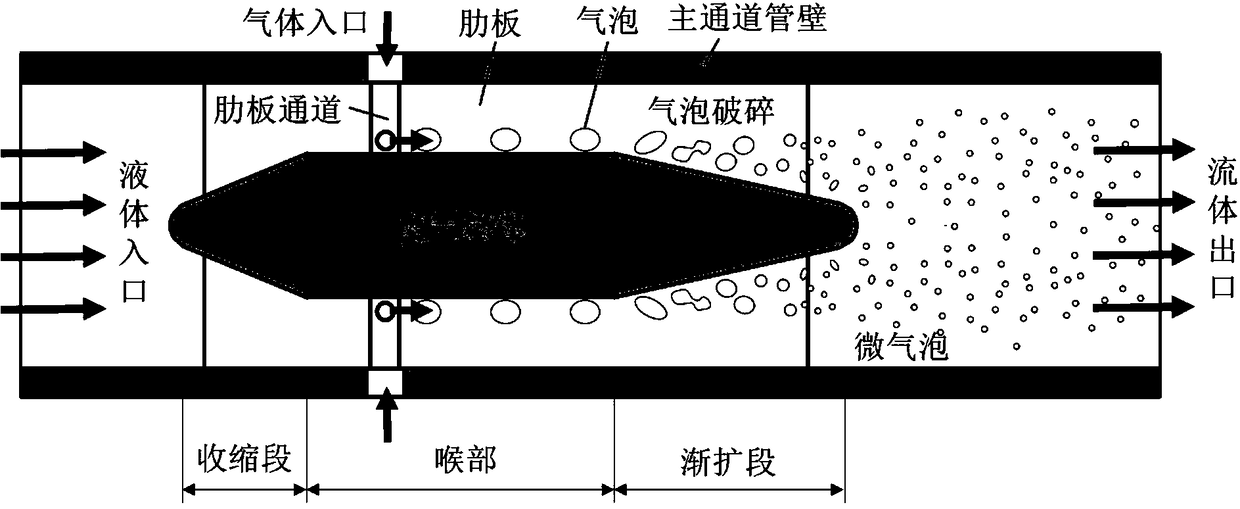

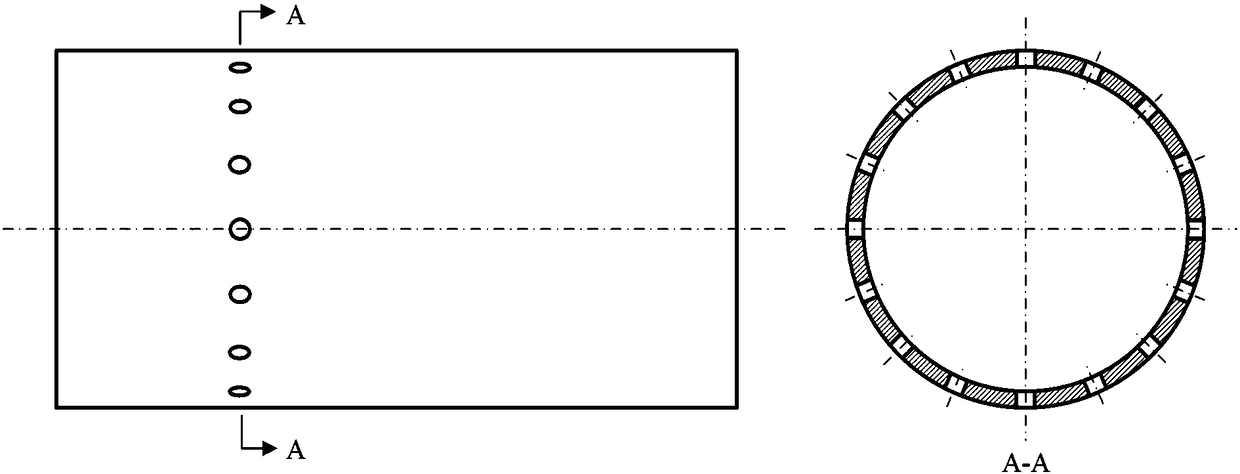

[0026] The invention discloses a Venturi-type bubble generating device with multiple Venturi structural units, which comprises an air intake channel (1), a shell (2), ribs (3), a built-in core (4) and a mounting flange ( 5); wherein, the air inlet channel is composed of a gas inlet (1.1), a shunt channel (1.2) and an air inlet ring cavity (1.3); the liquid is injected from the housing inlet (2.1), and the gas-liquid mixed fluid is injected from the housing outlet (2.3 ) flow out; there are 16 ribs (3) in total, which are evenly arranged on the circumference, and form 16 parallel Venturi structural units with the shell (2) and the built-in core (4); the gas passes through the air inlet (2.2) of the shell Enter the radial channel (3.1) of the rib plate, and inject into the Venturi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com