Machining process method of large forge piece lifting hook

A processing technology and technology for large-scale forgings, applied in the processing technology field of large-scale forging hooks, can solve the problems of large machining allowance from forging blanks to finished products, affecting machining accuracy and surface quality, and insufficient overhang length of tool shank, etc. Ensure mechanical properties, improve appearance quality, and ensure the effect of internal and external quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with specific drawings and embodiments.

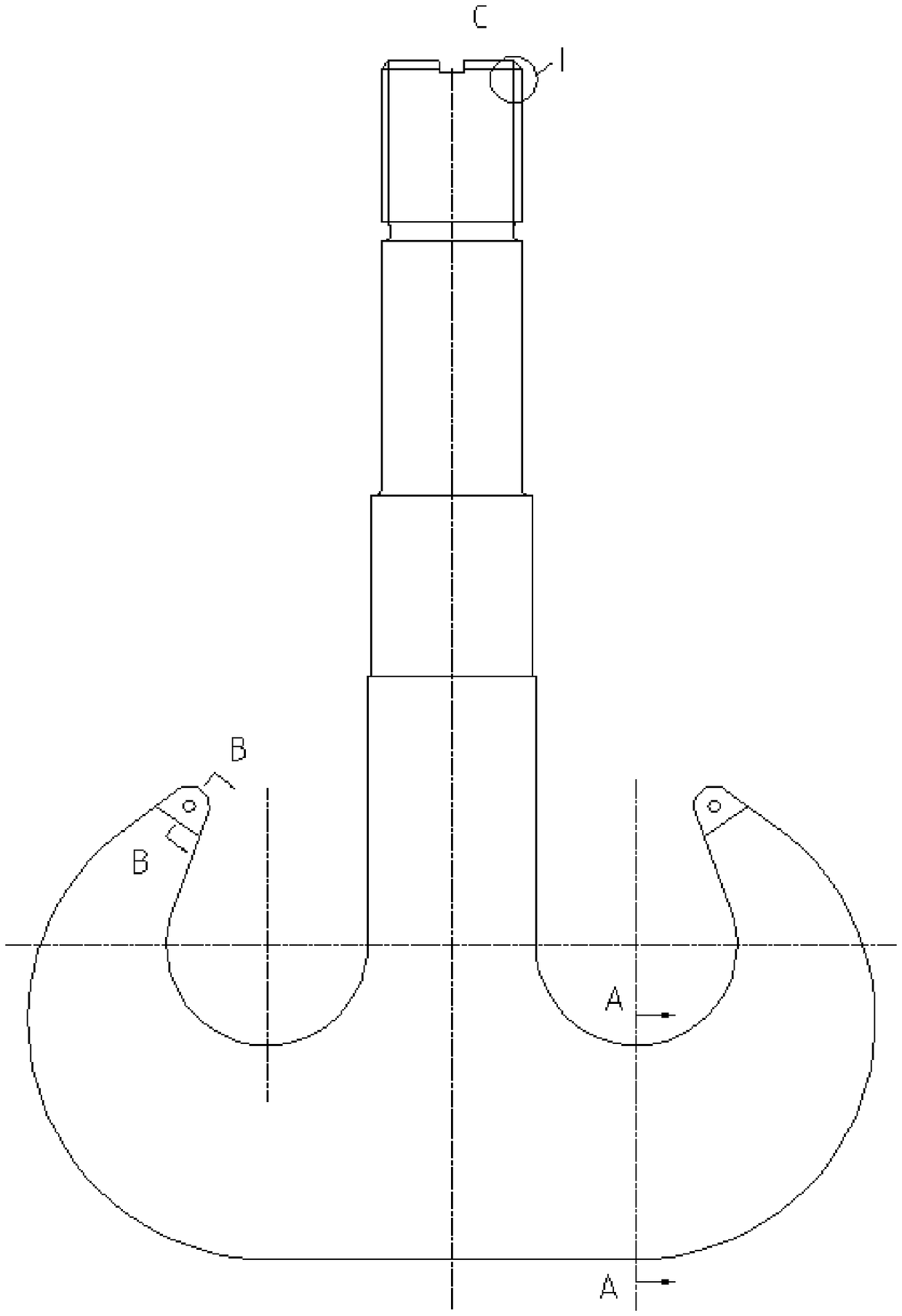

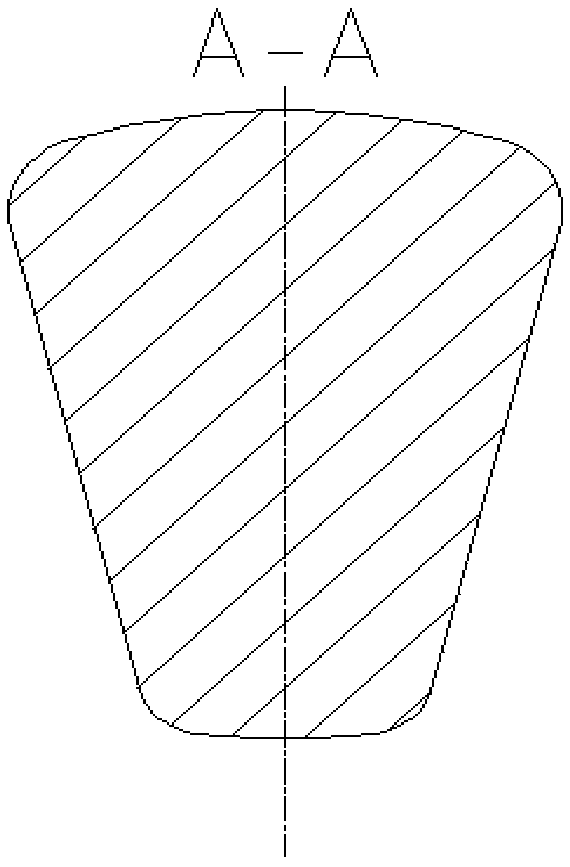

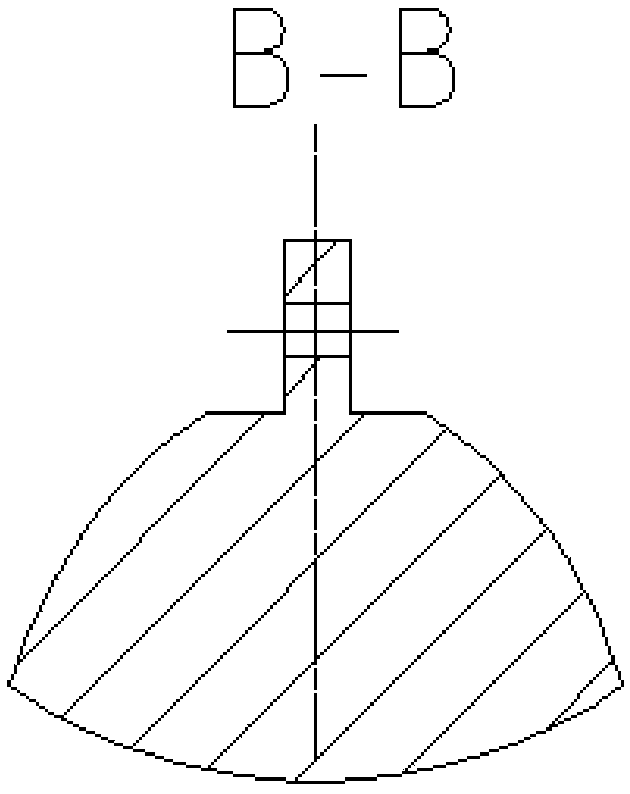

[0040] like Figure 1-5 Shown, a kind of processing technology method of large forging hook, is characterized in that, comprises the following steps:

[0041] Step 1, material selection and cutting

[0042] DG20Mn, Q345qD, Q420qD, 35CrMo, 34CrNiMo, 34Cr2Ni2Mo or 30Cr2Ni2Mo (34CrNiMo6) high-quality alloy steel ingots are used for blanking;

[0043] Step 2. Forging

[0044] Control the total forging ratio of the steel ingot forging hook, heat the material in the heating furnace, after heating to the set temperature, put the hook body on the hydraulic hammer and large equipment to forge the hook body into a square, and the rod of the hook body is made of a manipulator Flip upsetting and pull out into a round shape, keep the final forging temperature of the workpiece, put it in a sandbox for heat preservation and slow cooling after forging;

[0045] Step 3, nor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com