La and Cu doped BaFeO3-delta based ceramic oxygen permeable membrane material and preparation method thereof

An oxygen-permeable membrane and matrix material technology, applied in chemical instruments and methods, separation methods, membrane technology, etc., can solve problems such as unfavorable oxygen vacancy transmission, unit cell shrinkage, etc., achieve stable cubic phase structure, and improve oxygen permeability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

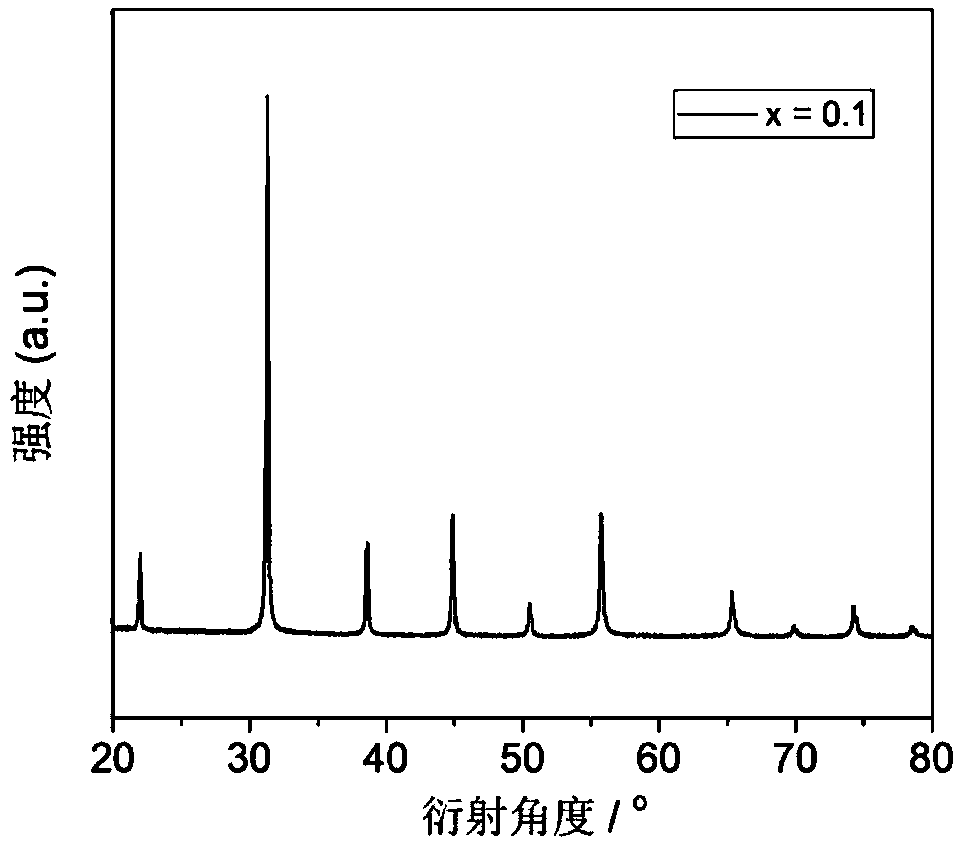

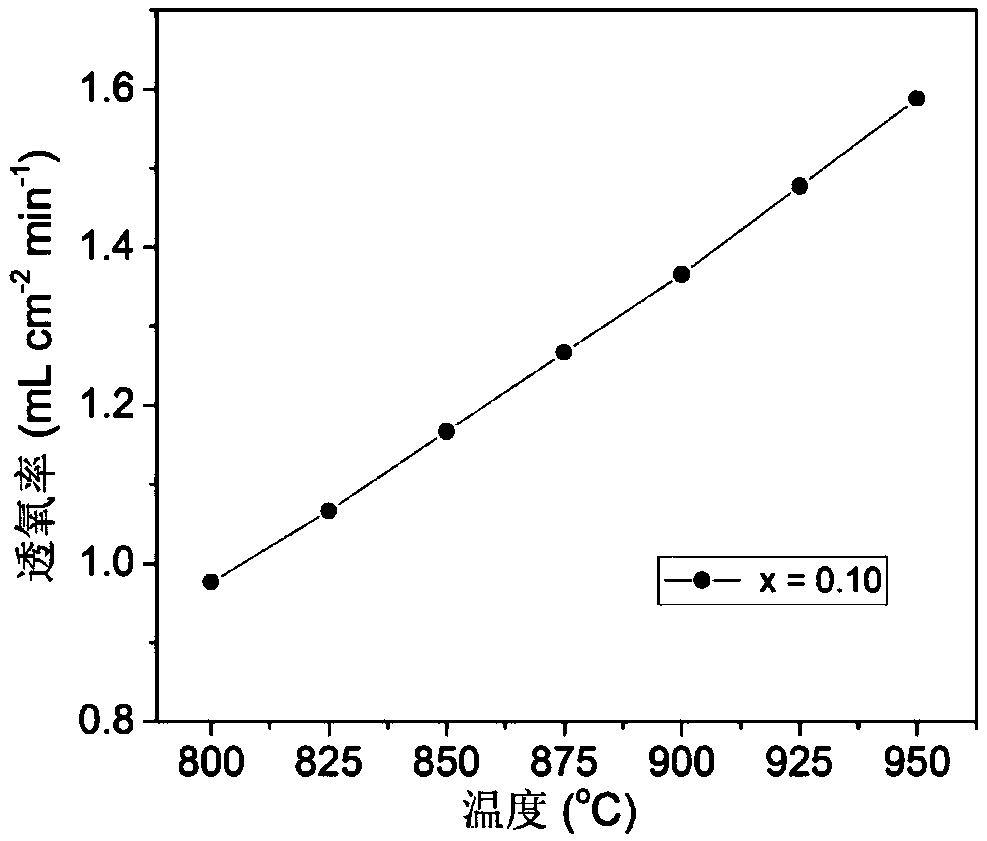

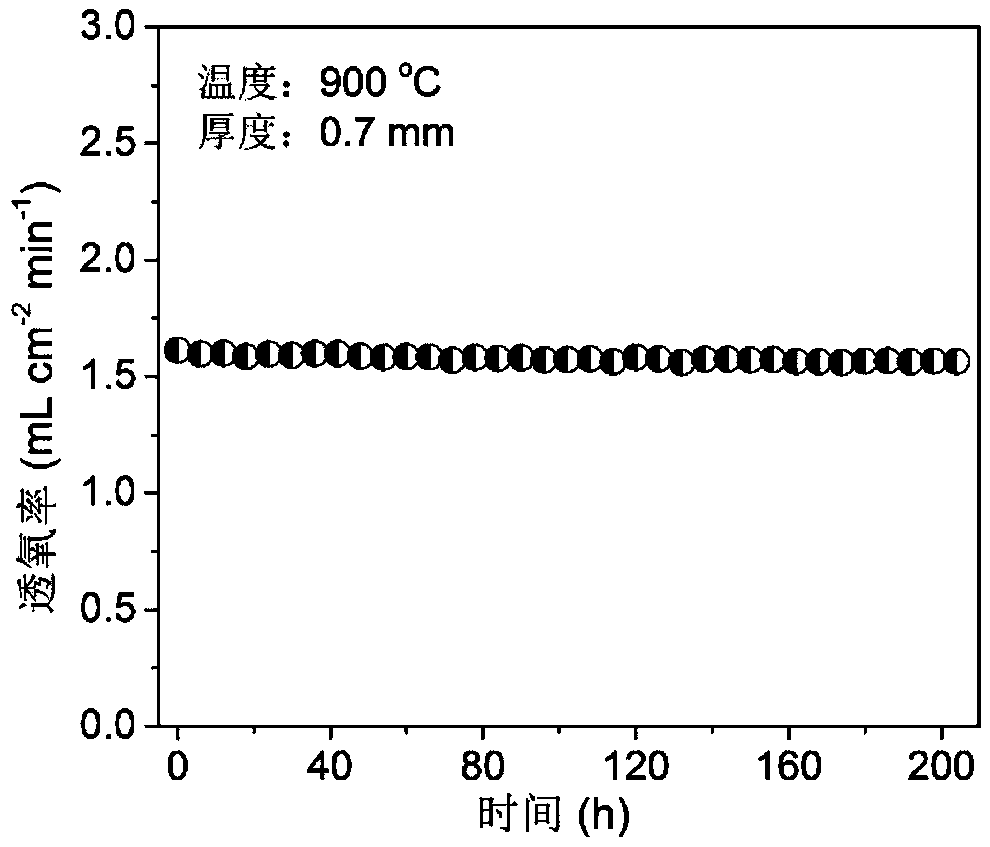

[0019] Example 1: Ba 0.975 La 0.025 Fe 0.9 Cu 0.1 o 3-δ Citric acid-nitrate synthesis

[0020] a) Add 0.163g La 2 o 3 , 10.192g Ba(NO 3 ) 2 , 14.544g Fe(NO 3 ) 3 9H 2 O, 0.966gCu(NO 3 ) 2 ·3H 2 O was dissolved in 400 mL of deionized water and 17 mL of 65 wt% HNO was added 3 , stirring for 6 hours;

[0021] b) After that, 23.380 g of ethylenediaminetetraacetic acid and 25.217 g of citric acid were added to the above solution, and the pH value of the solution was adjusted to 8 with 28 wt% ammonia water;

[0022] c) Subsequently, the mixed solution was evaporated in a water bath at 80°C to obtain a colloid, and the colloid was moved to an oven and ignited at 250°C to obtain a precursor powder;

[0023] d) Treat the precursor powder in an air atmosphere at 800°C for 8 hours. After cooling to room temperature, transfer it to a mortar, add 1wt% PVA and mix evenly. Use a mold to dry press the mixed precursor under a pressure of 200MPa forming. After sintering at 110...

Embodiment 2

[0024] Example 2: Ba 0.975 La 0.025 Fe 0.925 Cu 0.075 o 3-δ Citric acid-nitrate synthesis

[0025] a) Add 0.163g La 2 o 3 , 10.192g Ba(NO 3 ) 2 , 14.948g Fe(NO 3 ) 3 9H 2 O, 0.725gCu(NO 3 ) 2 ·3H 2 O was dissolved in 400 mL of deionized water and 20 mL of 65 wt% HNO was added 3 , stirred for 2 hours;

[0026] b) After that, 46.76g ethylenediaminetetraacetic acid and 25.217g citric acid were added to the above solution, and the pH value of the solution was adjusted to 6 with 28wt% ammonia water;

[0027] c) Then evaporate the mixed solution in a 60°C water bath to obtain a colloid, and move the colloid to an oven and ignite it at 200°C to obtain a precursor powder;

[0028] d) Treat the precursor powder in an air atmosphere at 400°C for 12 hours. After cooling to room temperature, transfer it to a mortar, add 1wt% PVA and mix evenly. Use a mold to dry press the mixed precursor under a pressure of 100MPa forming. After sintering at 1200℃ for 4h in air atmospher...

Embodiment 3

[0029] Example 3: Ba 0.975 La 0.025 Fe 0.85 Cu 0.15 o 3-δ Citric acid-nitrate synthesis

[0030] a) Add 0.163g La 2 o 3 , 10.192g Ba(NO 3 ) 2 , 13.736g Fe(NO 3 ) 3 9H 2 O, 1.450gCu(NO 3 ) 2 ·3H 2 O was dissolved in 400 mL of deionized water and 13 mL of 65 wt% HNO was added 3 , stirring for 10 hours;

[0031] b) After that, 35.070 g of ethylenediaminetetraacetic acid and 33.621 g of citric acid were added to the above solution, and the pH value of the solution was adjusted to 12 with 28 wt% ammonia water;

[0032] c) Then evaporate the mixed solution in a 100°C water bath to obtain a colloid, and move the colloid to an oven and ignite it at 400°C to obtain a precursor powder;

[0033] d) Treat the precursor powder in an air atmosphere at 900°C for 6 hours. After cooling to room temperature, transfer it to a mortar, add 1wt% PVA and mix evenly. Use a mold to dry press the mixed precursor under a pressure of 300MPa forming. After sintering at 1000℃ for 15h in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com