Method and device for continuously preparing pivaloyl chloride

A technology for crude pivaloyl chloride and pivaloyl chloride, which is applied to the preparation of carboxylic anhydrides and organic chemistry, can solve the problems of long separation reaction time, many by-product impurities, and long time, and achieve shortened reaction time, high conversion efficiency, High conversion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

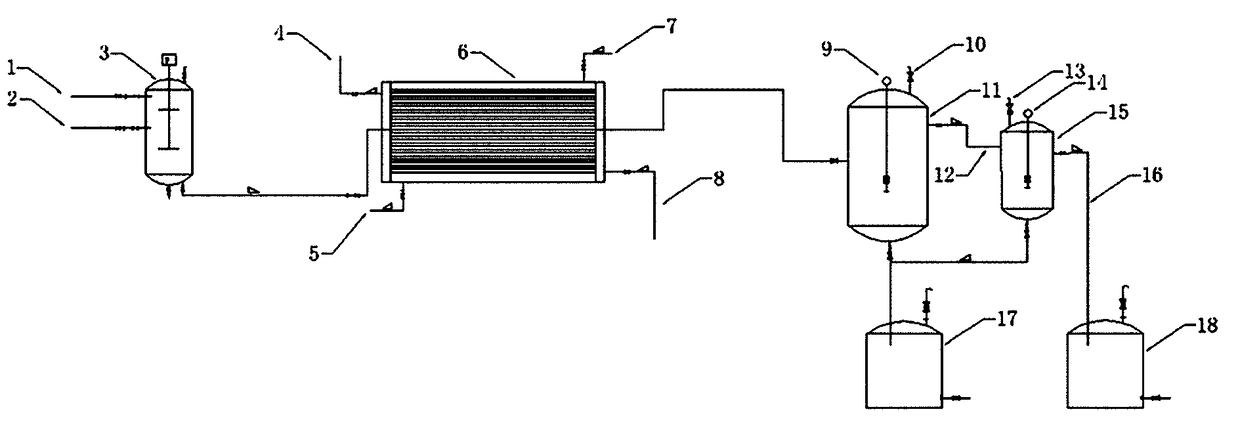

Image

Examples

Embodiment 1

[0029] This embodiment relates to a kind of method for continuously preparing pivaloyl chloride, and concrete steps are as follows:

[0030] (1) Feed the raw materials: feed the raw material pivalic acid through the pivalic acid delivery pipe at a flow rate of 167kg / h, and add phosphorus trichloride into the raw material mixer through the phosphorus trichloride delivery pipe at a flow rate of 93.5kg / h. The feed time of a kind of raw material is 2 hours;

[0031] (2) Chlorination reaction: Stir the raw materials in step (1) evenly and transport them to the 4 2- / ZrO 2 -Sm 2 o 3 In the microchannel reactor of the catalyst, the pressure is 20kPa, the temperature is 40°C, the residence time is 20s, and the chlorination reaction solution is obtained;

[0032] (3) Preparation of crude pivaloyl chloride: the chlorination reaction solution prepared in step (2) first enters the chromatography tank for chromatography, the lower phosphorous acid phase is separated into the crude pho...

Embodiment 2

[0037] This embodiment relates to a kind of method for continuously preparing pivaloyl chloride, and concrete steps are as follows:

[0038] (1) Feed raw materials: feed raw pivalic acid through the pivalic acid delivery pipe at a flow rate of 167kg / h, and add phosphorus trichloride into the raw material mixer through the phosphorus trichloride delivery pipe at a flow rate of 50kg / h. The feeding time of raw materials is 2 hours;

[0039] (2) Chlorination reaction: Stir the raw materials in step (1) evenly and transport them to the 4 2- / ZrO 2 -Sm 2 o 3 In the microchannel reactor of the catalyst, the pressure is 25kPa, the temperature is 45°C, the residence time is 24s, and the chlorination reaction solution is obtained;

[0040] (3) Preparation of crude pivaloyl chloride: the chlorination reaction solution prepared in step (2) first enters the chromatography tank for chromatography, the lower phosphorous acid phase is separated into the crude phosphorous acid storage tan...

Embodiment 3

[0045] This embodiment relates to a kind of method for continuously preparing pivaloyl chloride, and concrete steps are as follows:

[0046] (1) Feed the raw materials: feed pivalic acid as the raw material through the pivalic acid delivery pipe at a flow rate of 167kg / h, and add phosphorus trichloride into the raw material mixer through the phosphorus trichloride delivery pipe at a flow rate of 92kg / h. The feeding time of raw materials is 2 hours;

[0047] (2) Chlorination reaction: Stir the raw materials in step (1) evenly and transport them to the 4 2- / ZrO 2 -Sm 2 o 3 In the microchannel reactor of the catalyst, the pressure is 20kPa, the temperature is 50°C, the residence time is 25s, and the chlorination reaction solution is obtained;

[0048] (3) Preparation of crude pivaloyl chloride: the chlorination reaction solution prepared in step (2) first enters the chromatography tank for chromatography, the lower phosphorous acid phase is separated into the crude phosphor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com