A polyvinyl alcohol-based film with good durability and its preparation method

A polyvinyl alcohol-based film and technology of polyvinyl alcohol-based film, applied in the field of polyvinyl alcohol-based film and its preparation, can solve the problems of poor optical properties and tensile properties of polyvinyl alcohol-based films, poor product durability, uneven dyeing, etc. , to achieve the effect of smooth surface, uniform material mixing and uniform dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

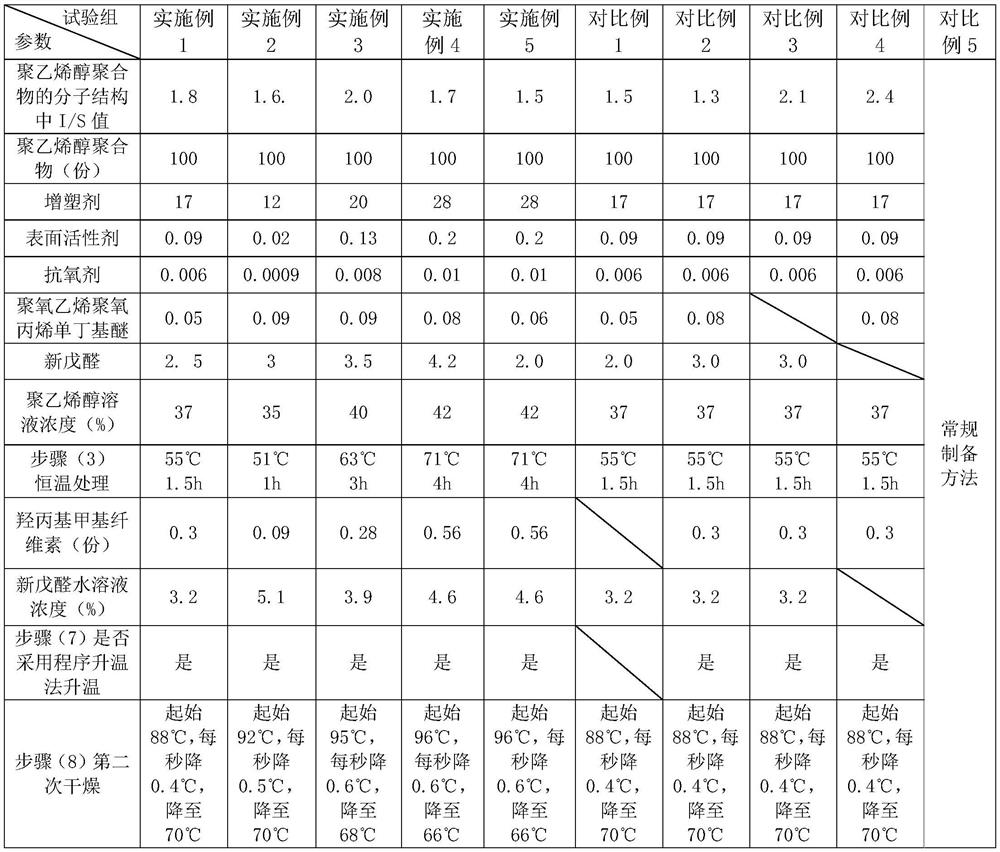

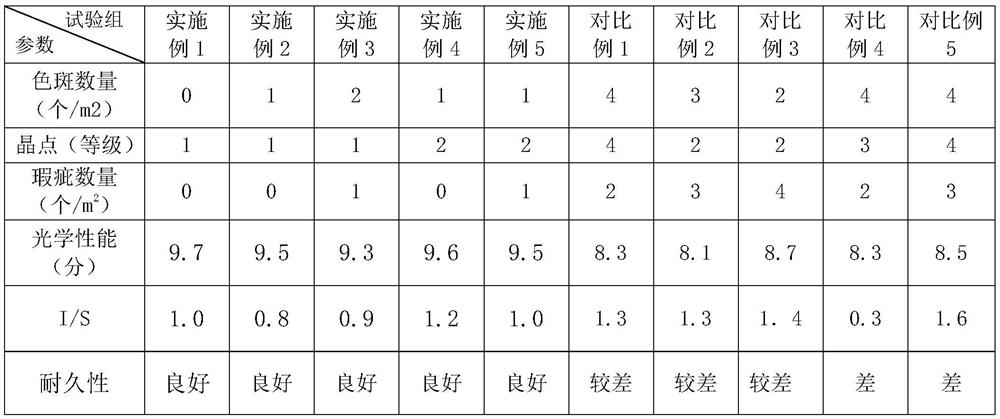

Examples

Embodiment 1

[0035] This embodiment discloses a method for preparing a polyvinyl alcohol-based film with good durability, comprising the following steps:

[0036] (1) Test the molecular structure of polyvinyl alcohol-based polymers by proton nuclear magnetic spectroscopy, and calculate the ratio of the isotactic content (I) to the syndiotactic content (S) in the molecular structure, and select a polymer with I / S of 1.8 Vinyl alcohol polymer. H NMR testing of polyvinyl alcohol polymers 1 H-NMR experiments, 1 All H-NMR experiments were carried out on a Bruker AV4000 nuclear magnetic resonance instrument; 1 In the H-NMR experiment, DMSO was used as a solvent (99.9% deuterium), TMS calibration, the concentration of polyvinyl alcohol polymer was 2.5mg / 0.5ml, and the test was carried out at room temperature;

[0037] The polyvinyl alcohol polymer tested in this step is to infiltrate the 100-120 mesh ordinary polyvinyl alcohol powder with HCl, and carry out solid-liquid mixing with diketene at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com