Epoxy resin composite board for vacuum plastic film mold

An epoxy resin and vacuum suction technology, which is applied in the field of epoxy resin composite panels for vacuum suction film molds, can solve problems such as easily affecting the shape of the vacuum suction film, easy deformation of aluminum alloys, and changes in the shape of the mold, etc. The effect of reducing the frequency of installation and maintenance, not easy to deform, and reducing the frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

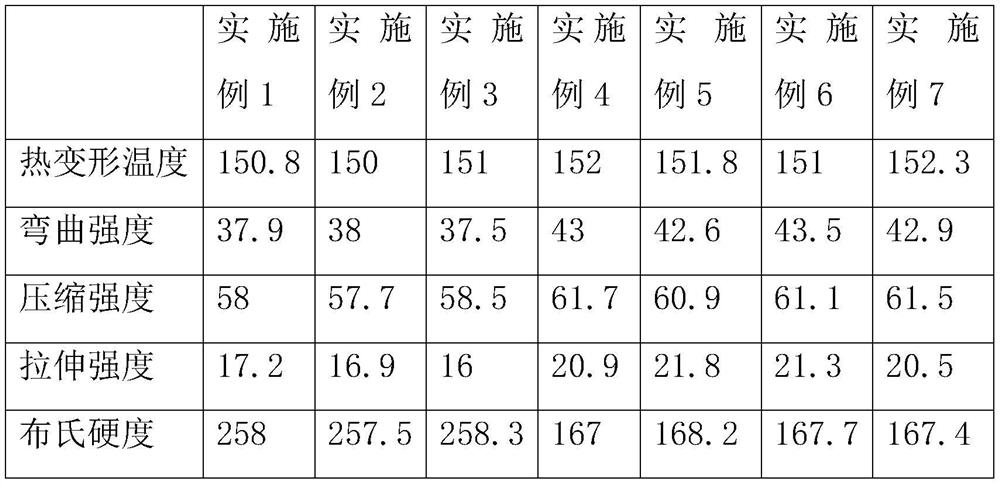

Embodiment 1

[0042] An epoxy resin composite board for a vacuum blister film mold, comprising the following components in parts by mass:

[0043]93 parts of E-55 epoxy resin; 16 parts of curing agent; 15 parts of polyamideimide; 0.5 parts of defoamer.

[0044] In this embodiment, the curing agent is T31 curing agent.

[0045] In this embodiment, the defoamer is emulsified silicone oil.

[0046] The preparation method of epoxy resin composite board is as follows:

[0047] (1) In a 200L reactor, under normal temperature conditions, add 93kg of E-55 epoxy resin and stir at a speed of 40r / min;

[0048] (2) Add 16kg of T31 curing agent, 15kg of polyamideimide, and 0.5kg of emulsified silicone oil while stirring;

[0049] (3) After stirring and mixing uniformly, the uniformly mixed mixture is poured onto a mold to obtain an epoxy resin composite board.

Embodiment 2

[0051] An epoxy resin composite board for a vacuum blister film mold, comprising the following components in parts by mass:

[0052] 108.5 parts of E-51 epoxy resin; 18.5 parts of curing agent; 17.5 parts of polyamideimide; 0.55 parts of defoamer.

[0053] In this embodiment, the curing agent is T32 curing agent.

[0054] In this embodiment, the defoamer is polyoxyethylene polyoxypropanolamine ether.

[0055] The preparation method of epoxy resin composite board is as follows:

[0056] (1) In a 200L reactor, under normal temperature conditions, add 108.5kg of E-51 epoxy resin and stir at a speed of 40r / min;

[0057] (2) Add 18.5kg of T32 curing agent, 17.5kg of polyamideimide, and 0.55kg of polyoxyethylene polyoxypropanolamine ether while stirring;

[0058] (3) After stirring and mixing uniformly, the uniformly mixed mixture is poured onto a mold to obtain an epoxy resin composite board.

Embodiment 3

[0060] An epoxy resin composite board for a vacuum blister film mold, comprising the following components in parts by mass:

[0061] 124 parts of E-44 epoxy resin; 21 parts of curing agent; 20 parts of polyamideimide; 0.6 parts of defoamer.

[0062] In this embodiment, the curing agent is T33 curing agent.

[0063] In this embodiment, the defoaming agent is polyoxypropylene oxide ethylene glyceryl ether.

[0064] The preparation method of epoxy resin composite board is as follows:

[0065] (1) In a 200L reactor, under normal temperature conditions, add 124kg of E-44 epoxy resin and stir at a speed of 40r / min;

[0066] (2) Add 21kg of T32 curing agent, 20kg of polyamideimide, and 0.6kg of polyoxypropylene oxide glyceryl ether while stirring;

[0067] (3) After stirring and mixing uniformly, the uniformly mixed mixture is poured onto a mold to obtain an epoxy resin composite board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com