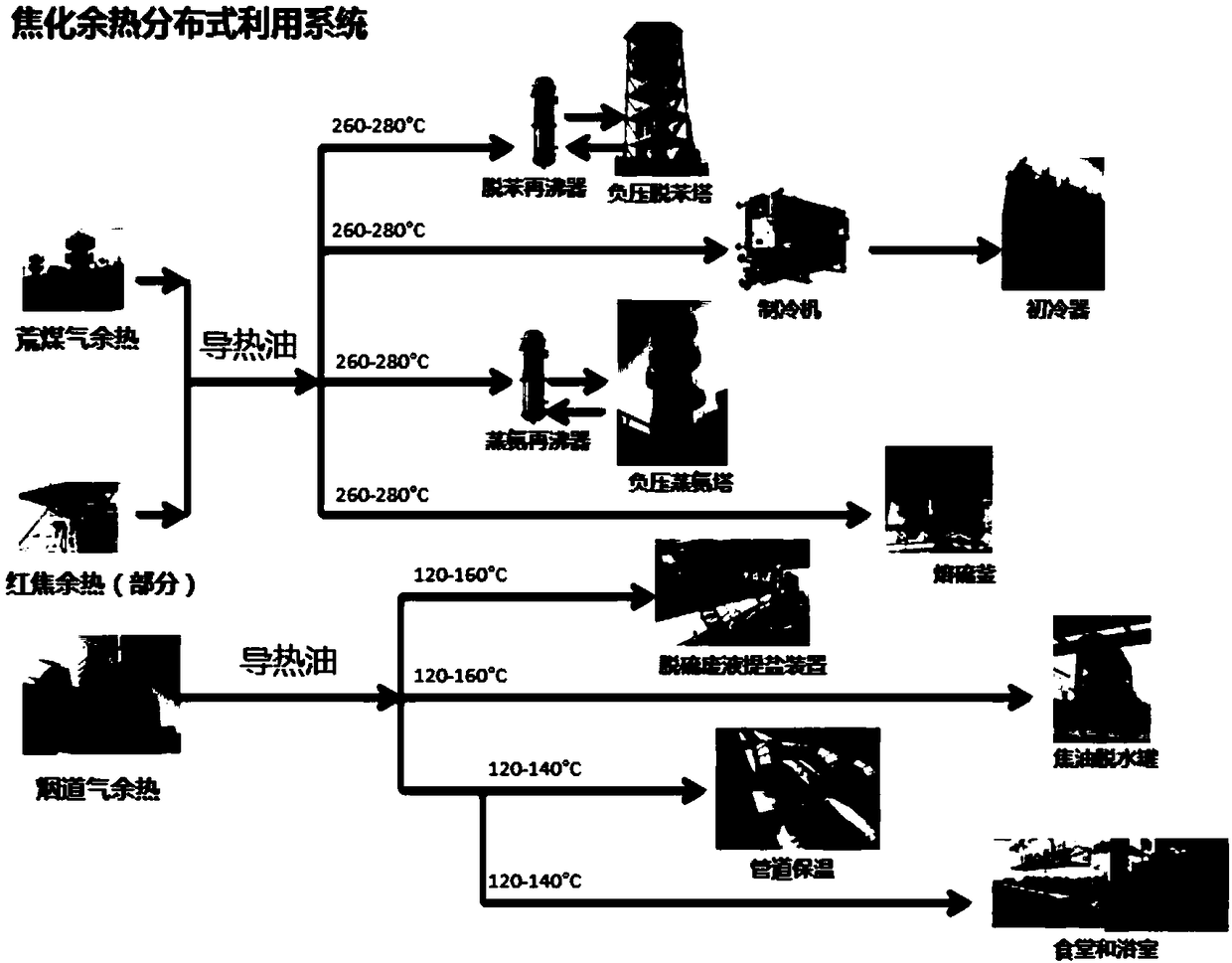

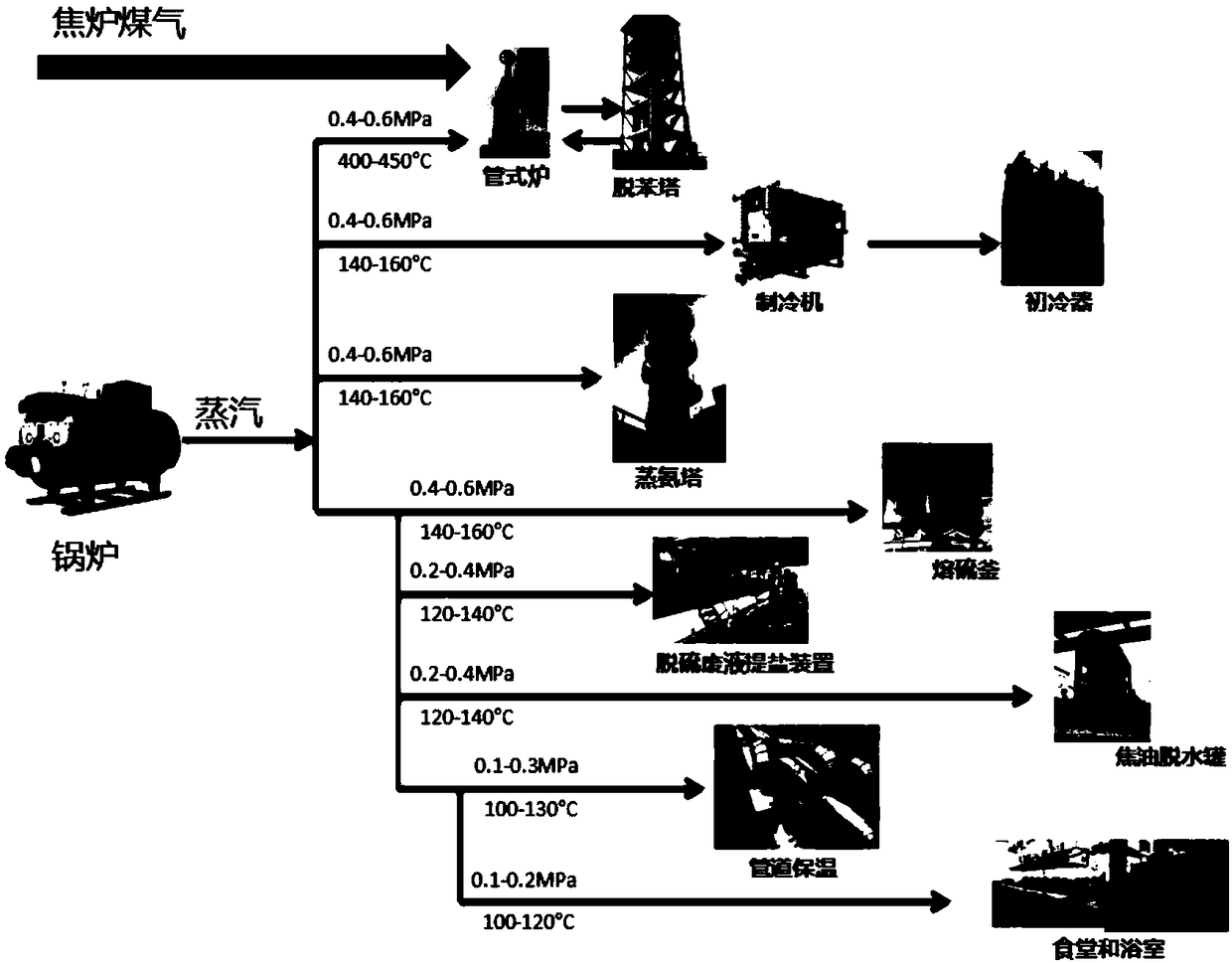

Distributed utilization method and utilization system of coking waste heat

A distributed and waste heat technology, used in the heating of coke ovens, coke ovens, coke oven parts, etc., can solve the problems of polluted waste water, low energy efficiency condensation waste water, etc., achieve high energy efficiency utilization rate, improve utilization cleanliness, avoid The effect of wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for distributed utilization of coking waste heat. The method includes the following steps: first convert the coking waste heat into gas, install a heat exchanger on the waste heat gas pipeline, and then make the heat transfer oil enter the heat exchanger to absorb the heat in the waste heat gas The heat transfer oil A is obtained, and the heat transfer oil A is supplied to the waste heat utilization equipment through the pipeline to obtain the used heat transfer oil B, and then the heat transfer oil B is returned to the heat exchanger through the pipeline for recycling.

[0065] The above method first converts the coking waste heat into gas, and installs a heat exchanger on the waste heat gas pipeline, and then makes the heat transfer oil enter the heat exchanger to absorb the heat in the waste heat gas to obtain heat transfer oil A, and supply heat transfer oil A to the waste heat through the pipeline Use the equipment to obtain the used heat transfer oil B, and t...

Embodiment 2

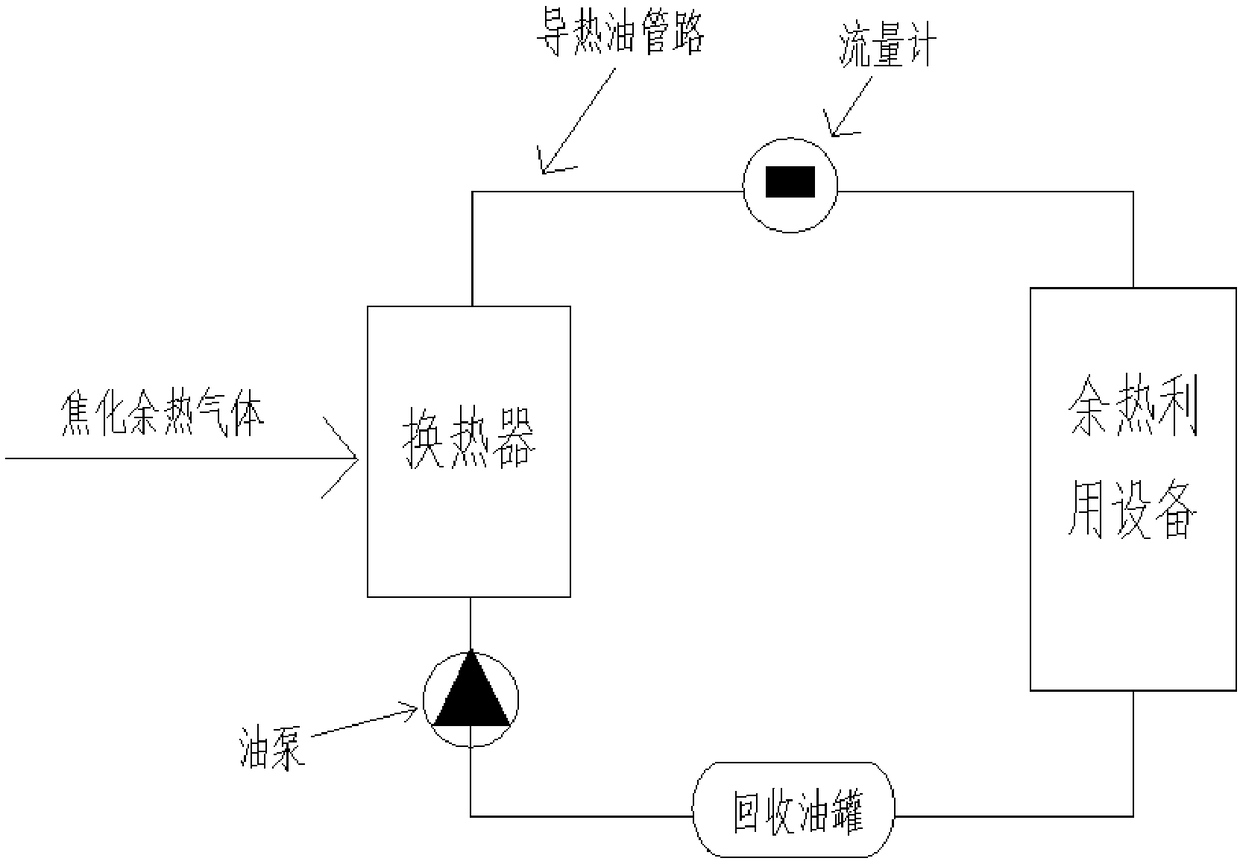

[0083] Such as image 3 As shown, a distributed utilization system of coking waste heat includes a heat conduction oil pipeline, an oil pump, a flow meter, a heat exchanger, waste heat utilization equipment, and a recovery oil tank; the oil pump, flow meter, exchange The heat exchanger, the waste heat utilization equipment and the recovery oil tank are cyclically connected in turn through the heat transfer oil pipeline.

[0084] The distributed utilization system of coking waste heat provided by the present invention includes heat conduction oil pipelines, oil pumps, flow meters, heat exchangers, waste heat utilization equipment and recovery oil tanks; the aforementioned distributed utilization system of coking waste heat uses oil pumps , Flowmeter, heat exchanger, waste heat utilization equipment and recovery oil tank are connected in turn through the heat transfer oil pipeline. The closed operation of the conductive oil in the utilization system not only improves the energy eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com