Preparation method of ytterbium metal

A metal, ytterbium oxide technology, applied in the field of metallurgy, can solve problems such as difficulty in purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The method for preparing ytterbium metal according to an embodiment of the present invention includes the following steps S1-S2:

[0021] S1. Mix ytterbium oxide and reducing agent in a vacuum higher than 5×10 -2 Under the condition of Pa, heat up to the first temperature at a speed of 10-15 °C / min and keep it warm until the vacuum degree is stable, then heat up to the second temperature at a speed of 2.5-10 °C / min and keep it warm for more than 30 min to carry out the reduction reaction. The obtained components are reduced products; wherein, the first temperature is 200-500°C, and the second temperature is 700-1000°C.

[0022] S2, reduce the product in a vacuum higher than 5 × 10 -4 Under the condition of Pa, the temperature is raised to the third temperature and kept for 5 to 20 hours, then the temperature is raised to the fourth temperature and the components evaporated during the time period from the third temperature to the fourth temperature are collected to obta...

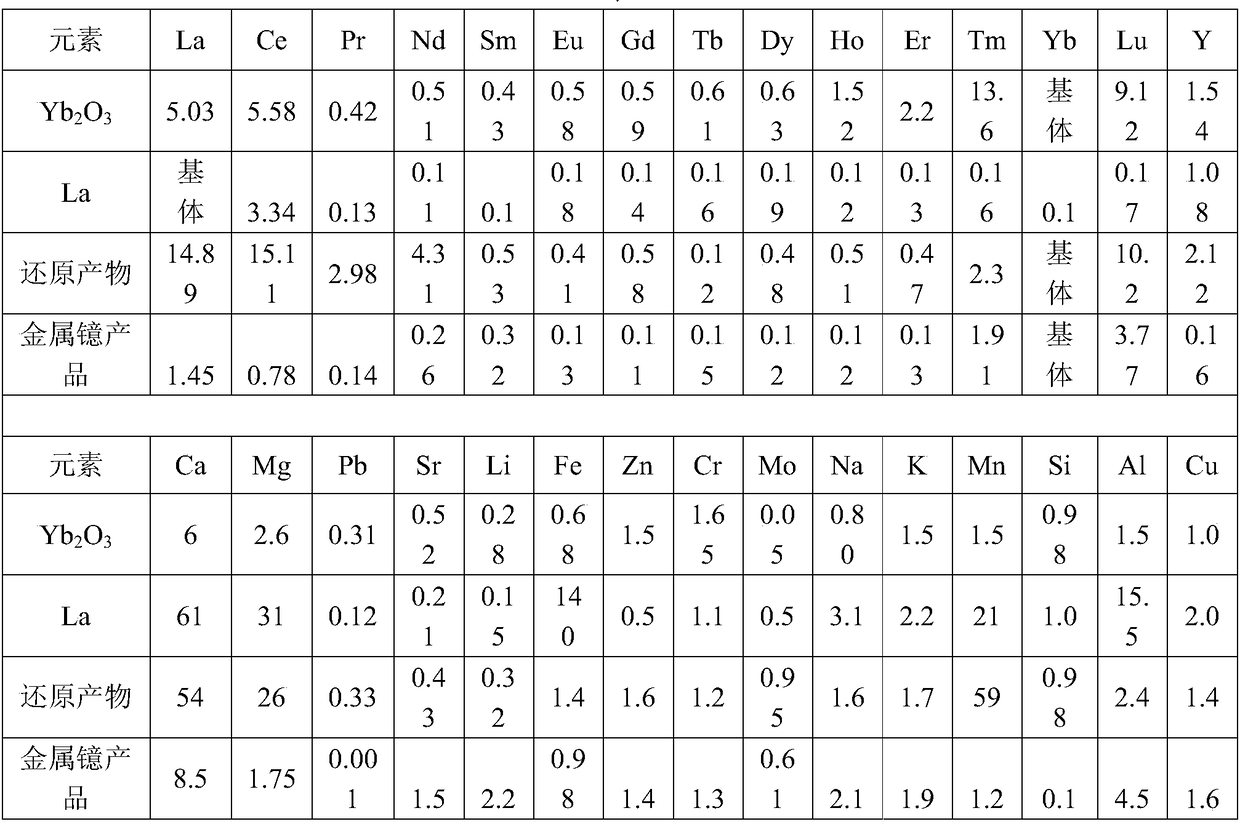

Embodiment 1

[0035] After making 1.6kg of metal lanthanum with a relative purity greater than 99.99% into lanthanum scrap, mix it with 1.9kg of ytterbium oxide with a relative purity greater than 99.995%, press it into blocks, and place it in a vacuum furnace at a vacuum degree higher than 5×10 -2 Under the condition of Pa, heat up from room temperature to 300°C at 10°C / min, keep warm until the vacuum degree is stable, then continue to heat up to 950°C at a speed of 5°C / min, keep warm for 60min, collect the evaporated components during the whole process, and obtain Reduction product.

[0036]Place the reduced product in a vacuum furnace at a vacuum degree higher than 5×10 -4 Under Pa conditions, first raise the temperature to 500°C and keep it warm for 5 hours to diffuse some impurities to the surface or evaporate them. Replace the collection bucket and remove the surface impurities, then continue to heat up to 750°C at a rate of 5°C / min to evaporate metal ytterbium. and collected to obta...

Embodiment 2

[0040] After making 2.4kg of metal lanthanum with a relative purity greater than 99.99% into lanthanum scrap, mix it with 2.85kg of ytterbium oxide with a relative purity greater than 99.995%, press it into a block, and place it in a vacuum furnace at a vacuum degree higher than 5×10 -2 Under the condition of Pa, heat up from room temperature to 300°C at 10°C / min, keep warm until the vacuum degree is stable, then continue to heat up to 850°C at a speed of 5°C / min, keep warm for 120min, collect the evaporated components during the whole process, and obtain Reduction product.

[0041] Place the reduced product in a vacuum furnace at a vacuum degree higher than 5×10 -4 Under Pa conditions, first raise the temperature to 500°C and keep it warm for 10 hours to diffuse some impurities to the surface or evaporate them. Replace the collection bucket and remove the surface impurities, then continue to heat up to 750°C at a speed of 5°C / min to evaporate metal ytterbium. and collected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com