Electrodeposition sensor based on polypyrrole (PPy)/metal porphyrin and preparation method and application of electrodeposition sensor

A metalloporphyrin and porphyrin electricity technology, applied in the direction of electrolytic organic material coating and other directions, can solve the problems of low conductivity at room temperature and cannot be used as a sensor or energy storage material, etc., and achieve a simple preparation process, good recycling performance, good gas The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

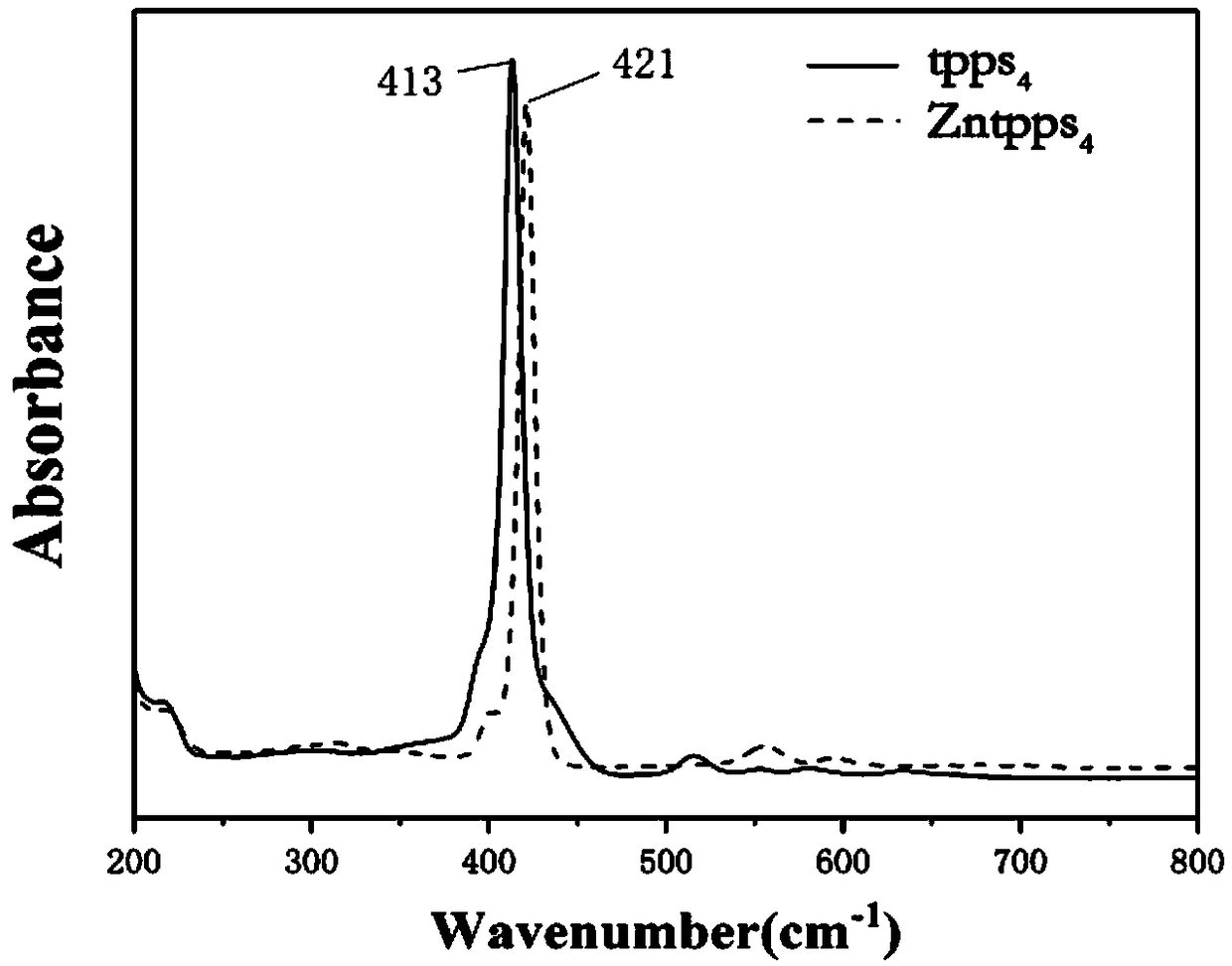

[0033] (1) Take 0.60g tetrakis (4-sodium sulfonate) phenyl porphyrin tpps 4 with 1.68g Zn(OAc) 2 2H 2 O was dissolved in 80 mL of deionized water and then heated to 120 °C. After reacting for 2h, adjust the pH of the solution to be 6.0, utilize methods such as acidic cation exchange resin column, dialysis to purify the solution, and dry to prepare tetrakis (4-sodium sulfonate) phenyl zinc porphyrin (Zntpps 4 ). to the resulting Zntpps 4 Conduct UV-Vis test, the test results are as follows figure 1 shown.

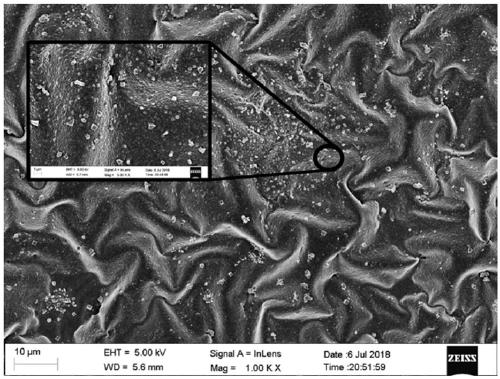

[0034] (2) Add 0.03mmol Zntpps 4Dissolve in 15mL deionized water, and obtain a homogeneous solution after ultrasonication for 5min. Add 15mL 2mol / L sulfuric acid solution to the homogeneous solution for acidification, then add 0.09mol Py into the solution and keep stirring vigorously to obtain a mixed solution as electrolyte. PPy / Zntpps was deposited on the surface of ITO-PET by constant voltage deposition (voltage 1V, deposition time 200s) 4 Electrodeposition senso...

Embodiment 2

[0039] (1) Take 0.60g tetrakis (4-sodium sulfonate) phenyl porphyrin tpps 4 with 0.73g Co(OAc) 2 4H 2 O was dissolved in 80 mL of deionized water and then heated to 100 °C. After reacting for 6h, adjust the pH of the solution to be 6.5, utilize methods such as acidic cation exchange resin column, dialysis to purify the solution, and dry to prepare tetrakis (4-sodium sulfonate) phenyl cobalt porphyrin (Cotpps 4 ).

[0040] (2) Add 0.06mmol Cotpps 4 Dissolve in 20mL deionized water, and obtain a homogeneous solution after ultrasonication for 10min. Add 10 mL of 2 mol / L sulfuric acid solution to the homogeneous solution for acidification, then add 0.06 mol of Py into the solution and keep stirring vigorously to obtain a mixed solution as an electrolyte. PPy / Cotpps was deposited on the surface of ITO-PET by constant voltage deposition (voltage 2V, deposition time 100s) 4 Electrodeposition sensors.

Embodiment 3

[0042] (1) Take 0.60g tetrakis (4-sodium sulfonate) phenyl porphyrin tpps 4 with 1.68g Fe(OAc) 2 2H 2 O was dissolved in 80 mL of deionized water and then heated to 80 °C. After reacting for 12 hours, adjust the pH of the solution to be 7.0, utilize methods such as acidic cation exchange resin column, dialysis to purify the solution, and dry to prepare tetrakis (4-sodium sulfonate) phenyl iron porphyrin (Fetpps 4 ).

[0043] (2) Add 0.09mmol Fetpps 4 Dissolve in 10mL deionized water, and obtain a homogeneous solution after ultrasonication for 10min. Add 20mL 2mol / L sulfuric acid solution to the homogeneous solution for acidification, then add 0.03mol Py into the solution and keep stirring vigorously to obtain a mixed solution as electrolyte. Deposit PPy / Fetpps on the surface of ITO-PET by constant voltage deposition (voltage 3V, deposition time 50s) 4 Electrodeposition sensors.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com