Graphene aerogel with carbonized sugar as three-dimensional skeleton and preparation method of graphene aerogel

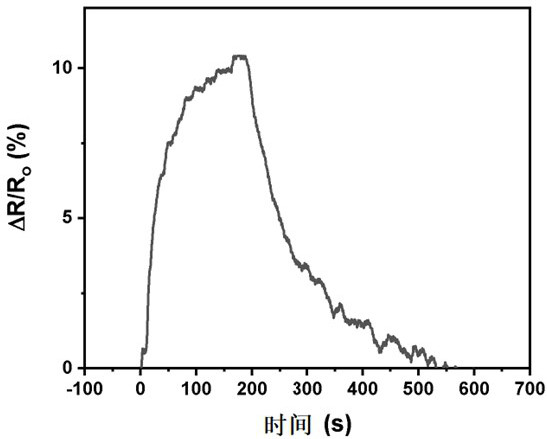

A graphene aerogel, three-dimensional skeleton technology, applied in graphene, chemical instruments and methods, separation methods, etc., can solve the problems of graphene sheet stacking, low sensitivity to low-concentration gases, and too complex, and achieve gas adsorption. Fast desorption, uniform pore size distribution and high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

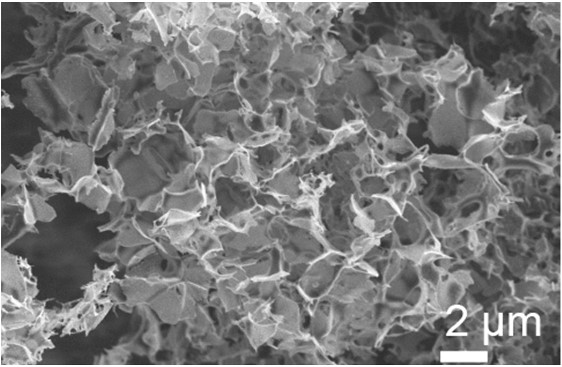

[0045] In the graphene oxide airgel, graphene oxide is carried on the three-dimensional skeleton of carbonized sugar in a single-layer structure; the average pore diameter of the graphene oxide airgel is 2.0 μm, and the specific surface area is 68.2 m 2 / g, the mass content of graphene oxide is 4.6%.

[0046] After testing, the graphene oxide sheet of the graphene oxide airgel with carbonized sugar as the three-dimensional skeleton is a single layer, the pore size distribution is uniform, the average pore size is 2.0 μm, the surface is smooth, has a macroporous structure, and the specific surface area is 68.2 m 2 / g.

[0047] After thermogravimetric detection, the mass content of graphene oxide was 4.6%.

[0048] A kind of preparation method embodiment 1 of graphene oxide airgel with carbonized sugar as three-dimensional skeleton

[0049] (1) After mixing 800mg sucrose, 15mg single-layer graphene oxide and 50mg sodium carbonate, add 1g of water, stir to dissolve, and dry at...

Embodiment 2

[0053] In the graphene oxide airgel, graphene oxide is carried on the three-dimensional skeleton of carbonized sugar in a multilayer structure; the average pore diameter of the graphene oxide airgel is 1.8 μm, and the specific surface area is 75.2 m 2 / g, the mass content of graphene oxide is 4.1%.

[0054] After testing, the graphene oxide sheet of the graphene oxide airgel with carbonized sugar as the three-dimensional skeleton is multi-layered, the pore size distribution is uniform, the average pore size is 1.8 μm, the surface is smooth, has a macroporous structure, and the specific surface area is 75.2 m 2 / g.

[0055] After thermogravimetric detection, the mass content of graphene oxide was 4.1%.

[0056] A kind of preparation method embodiment 2 of graphene oxide airgel with carbonized sugar as three-dimensional skeleton

[0057] (1) After mixing 800mg sucrose, 14mg multilayer graphene oxide and 60mg sodium carbonate, add 0.8g water, stir to dissolve, and dry at 50°C ...

Embodiment 3

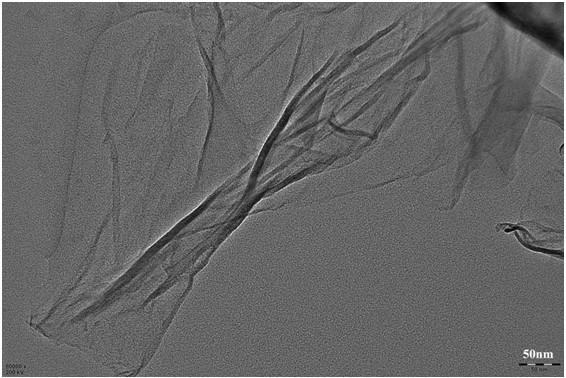

[0061] In the graphene airgel, reduced graphene oxide is carried on the three-dimensional skeleton of carbonized sugar in a single-layer structure; the average pore diameter of the graphene airgel is 1.9 μm, and the specific surface area is 72.7 μm 2 / g, the mass content of reduced graphene oxide is 4.2%.

[0062] Such as figure 1 As shown, the pore size distribution of the reduced graphene oxide airgel with carbonized sugar as the three-dimensional skeleton is uniform, the average pore size is 1.9 μm, the surface is smooth, has a macroporous structure, and the specific surface area is 72.7 m 2 / g.

[0063] Such as figure 2 As shown, the reduced graphene oxide sheet layer of the reduced graphene oxide airgel with carbonized sugar as a three-dimensional skeleton is a single layer.

[0064] According to thermogravimetric detection, the mass content of reduced graphene oxide was 4.2%.

[0065] A kind of preparation method embodiment 3 of the reduced graphene oxide airgel wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com