Upper dense and lower sparse double spiral fin heat exchanger

A fin heat exchanger and helical fin technology are applied in the field of upper dense and lower sparse double helical fin heat exchangers, which can solve the problems of difficult lightweight design and low efficiency, and achieve lightweight design and increased pressure drop. , the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

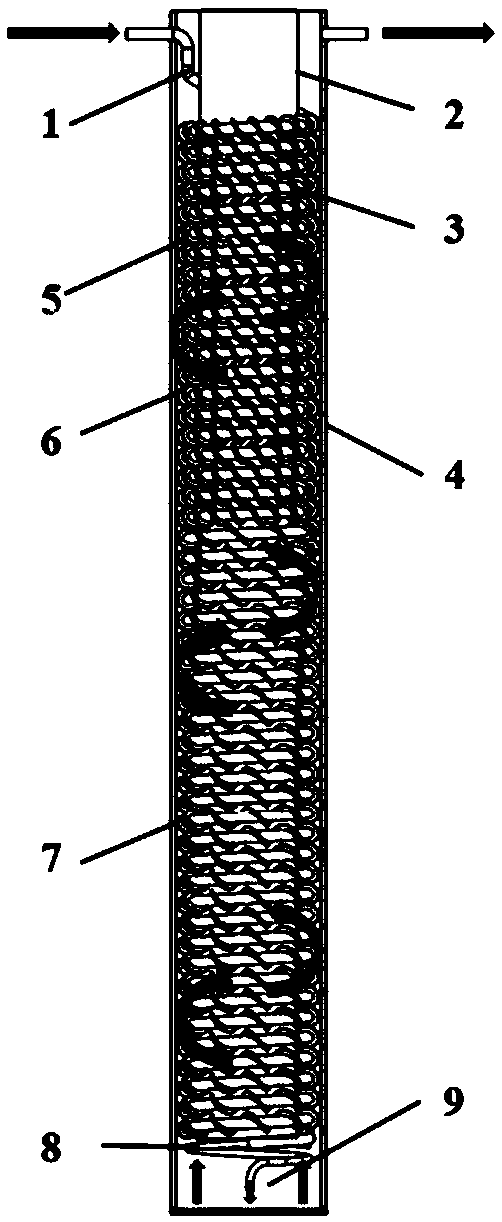

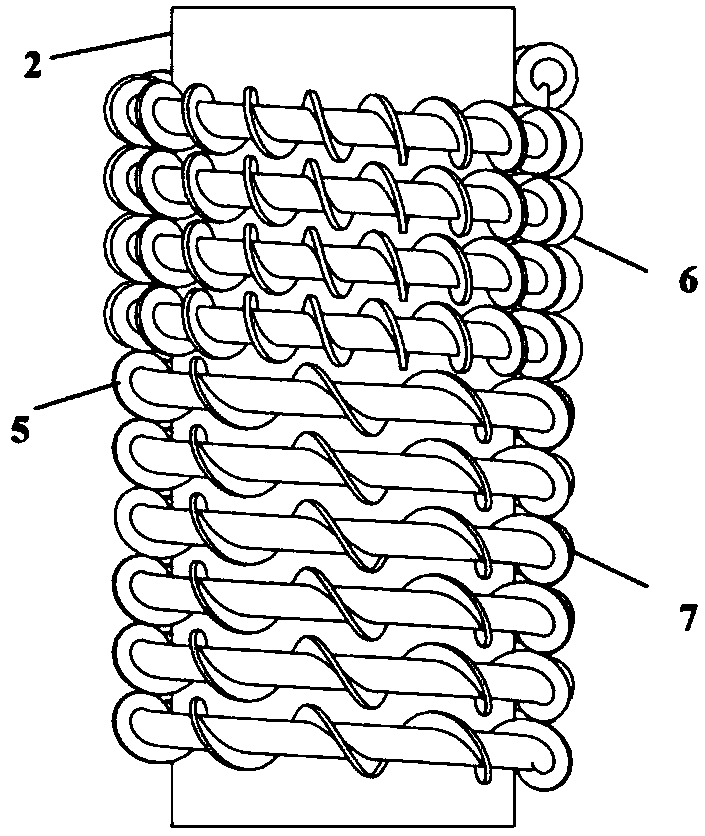

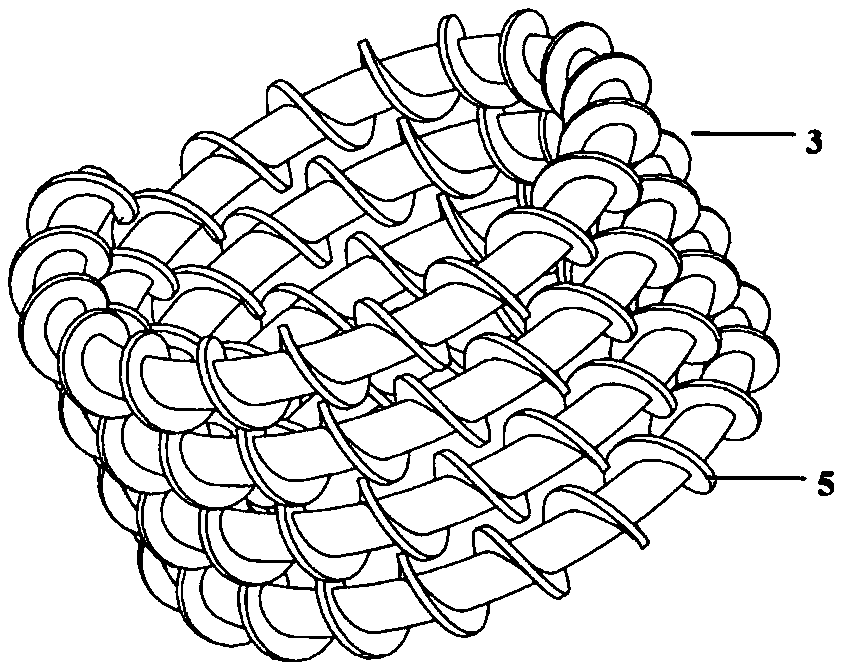

[0032] Such as figure 1 , Figure 2a , Figure 2bAs shown, this embodiment includes a mandrel 2 and a spiral capillary finned tube 3 spirally wound on the mandrel 2 in the axial direction. The shell 4 leaves a space to form an evaporation chamber 9. The spiral capillary finned tube 3 includes a capillary 1 and a spiral fin 5 wound on the capillary 1. The upper end of the sealed shell 4 is provided with a capillary inlet and a heat exchange tube respectively. The outlet of the capillary tube 1 is connected with the evaporation chamber 9, and a throttle valve 8 is also installed at the outlet; the spiral capillary finned tube 3 is divided into dense capillary finned tubes at the upper end according to the pitch of the spiral fins 5 6 and the sparse section of capillary finned tube 7 at the lower end form a structure of "dense top and sparse bottom", wherein the dense section of capillary finned tube 6 is located at the inlet of the thermal fluid, and the sparse section of capi...

Embodiment 2

[0039] The basic parameters are the same as those in Embodiment 1, but the pitch of each microelement of the helical capillary in the dense section and the sparse section changes linearly and continuously. The pitch calculation formula is shown in equation (6):

[0040]

[0041] In the formula: n=50, m=0.4n=20, α=0.3, β=1. By calculating the "upper denser lower sparser" structure in specific example 2 and comparing it with the two-stage "upper denser lower sparser" structure: Loss N d Basically the same, with a 24% reduction in material consumption.

Embodiment 3

[0043] This embodiment is a new type of countercurrent heat exchanger, specifically a countercurrent tube-row partition wall heat exchanger, which is composed of a base tube 10, dense fins 11, and sparse fins 12, such as Figure 4 shown. The dense fins 11 are located at the thermal fluid inlet section, the sparse fins 12 are located at the thermal fluid outlet section, and the boundary between the dense fins 11 and the sparse fins 12 is located at a position 40% to 50% away from the thermal fluid inlet. The hot fluid flows back and forth in the base pipe 10 , exchanges heat with the cold fluid through the fins, and at the same time cools itself. The structure of "dense top and sparse bottom" makes the heat exchange between the cold fluid and the hot fluid more intense at the dense fins 11, and the cooling effect on the hot fluid is better; while the resistance of the cold fluid at the sparse fins 12 is stronger small, flowing Losses are greatly reduced. The countercurrent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com