Rapid analysis method suitable for aluminum, iron and silicon content in aluminum iron alloy

A rapid analysis technology for aluminum-iron alloys, which is applied in the field of rapid analysis of aluminum and silicon content in iron and aluminum-iron alloys, can solve problems such as low efficiency and complicated process of determining the chemical composition of aluminum-iron alloys, and achieve simplified operation methods and daily analysis tasks, reducing analysis time-consuming effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

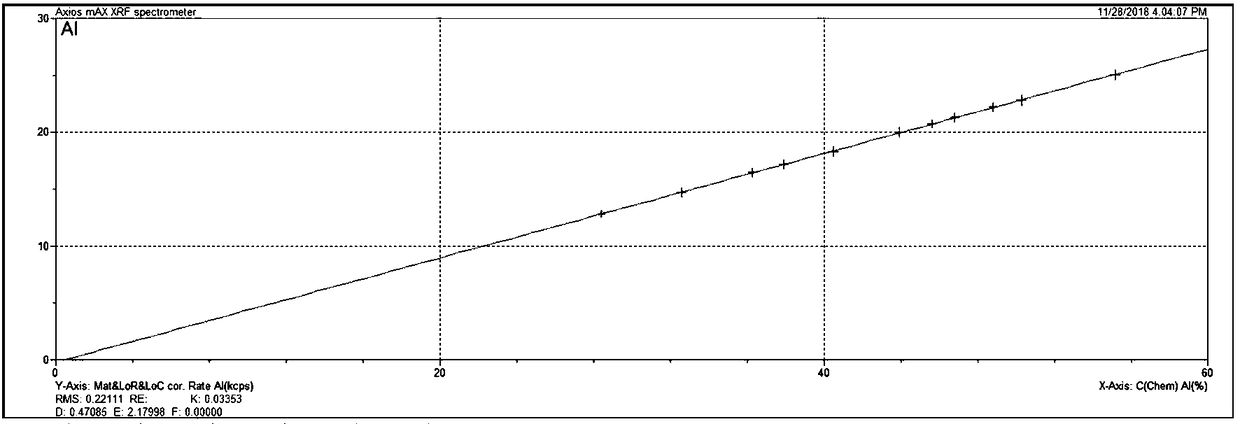

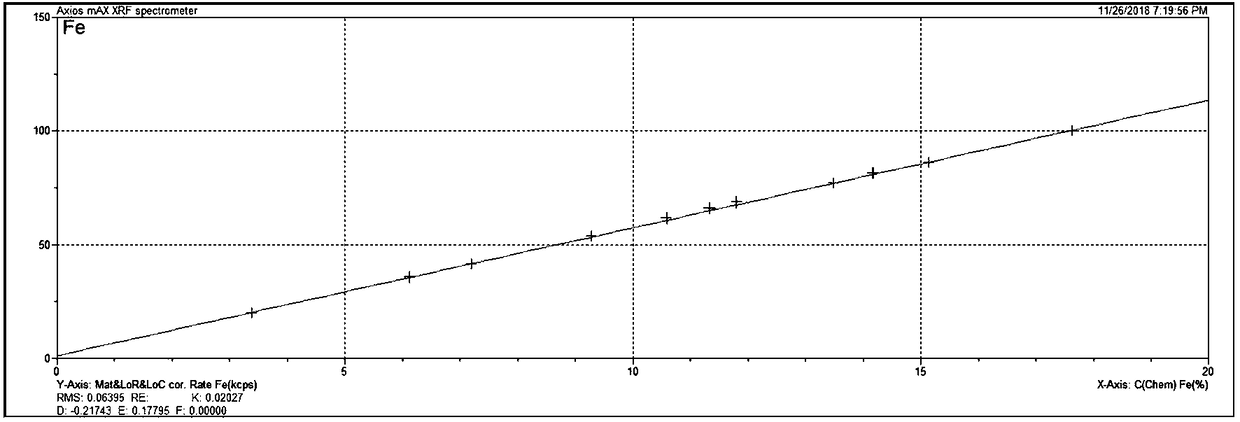

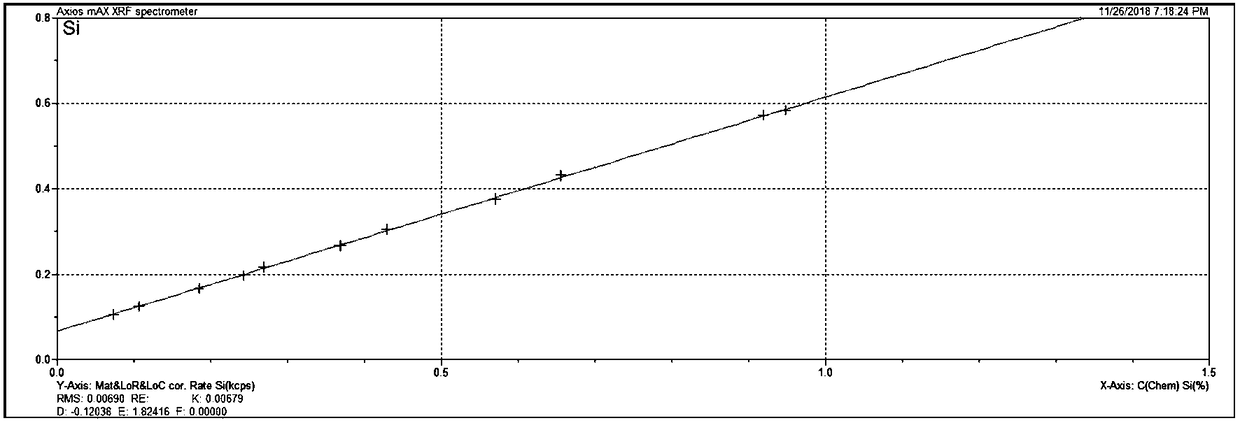

Image

Examples

Embodiment 1

[0036] The rapid analysis method of aluminum, iron, silicon content in the aluminum-iron alloy of the present embodiment comprises the following steps:

[0037] Step A, processing the sample to be analyzed: select the sample to be analyzed of the aluminum-iron alloy, and pass through a 150-mesh molecular sieve.

[0038] Step B, wall-hanging treatment: Put 7.0000g of anhydrous lithium tetraborate powder flux into the crucible, place the crucible in the muffle furnace, melt it at 1050°C for 10 minutes, take out the crucible and rotate it immediately, and put the molten The flux adheres to the inner wall of the crucible and forms a dense crucible protective layer after cooling.

[0039] Step C, preparation of the samples to be analyzed: 0.1500g of the samples to be analyzed obtained in step A, 0.5000g of barium peroxide and 0.5000g of lithium carbonate, mixed and stirred evenly, and the obtained mixture was spread flat in a crucible with a protective layer to avoid aluminum The ...

Embodiment 2

[0049] The rapid analysis method of aluminum, iron, silicon content in the aluminum-iron alloy of the present embodiment comprises the following steps:

[0050] Step A, processing the sample to be analyzed: select the sample to be analyzed of the aluminum-iron alloy and pass it through a 180-mesh molecular sieve.

[0051] Step B, wall-hanging treatment: Put 6.0000g of anhydrous lithium tetraborate powder flux into the crucible, place the crucible in the muffle furnace, melt it at 1050°C for 10 minutes, take out the crucible and rotate it immediately, and put the molten The flux adheres to the inner wall of the crucible and forms a dense crucible protective layer after cooling.

[0052] Step C, preparing the samples to be analyzed: Accurately weigh 0.2000 g of the samples to be analyzed obtained in step A, 0.5000 g of barium peroxide and 0.5000 g of lithium carbonate, mix and stir evenly, spread the obtained mixture in a crucible with a protective layer, Add 1.0000g of lithium...

Embodiment 3

[0057] The rapid analysis method of aluminum, iron, silicon content in the aluminum-iron alloy of the present embodiment comprises the following steps:

[0058] Step A, processing the sample to be analyzed: select the sample to be analyzed of the aluminum-iron alloy and pass it through a 200-mesh molecular sieve.

[0059] Step B, wall-hanging treatment: Put 6.0000g of anhydrous lithium tetraborate powder flux into the crucible, place the crucible in the muffle furnace, melt it at 1050°C for 10 minutes, take out the crucible and rotate it immediately, and put the molten The flux adheres to the inner wall of the crucible and forms a dense crucible protective layer after cooling.

[0060] Step C, preparing the samples to be analyzed: Accurately weigh 0.2000 g of the samples to be analyzed obtained in step A, 0.5000 g of barium peroxide and 0.5000 g of lithium carbonate, mix and stir evenly, spread the obtained mixture in a crucible with a protective layer, Add 1.0000g of lithium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com