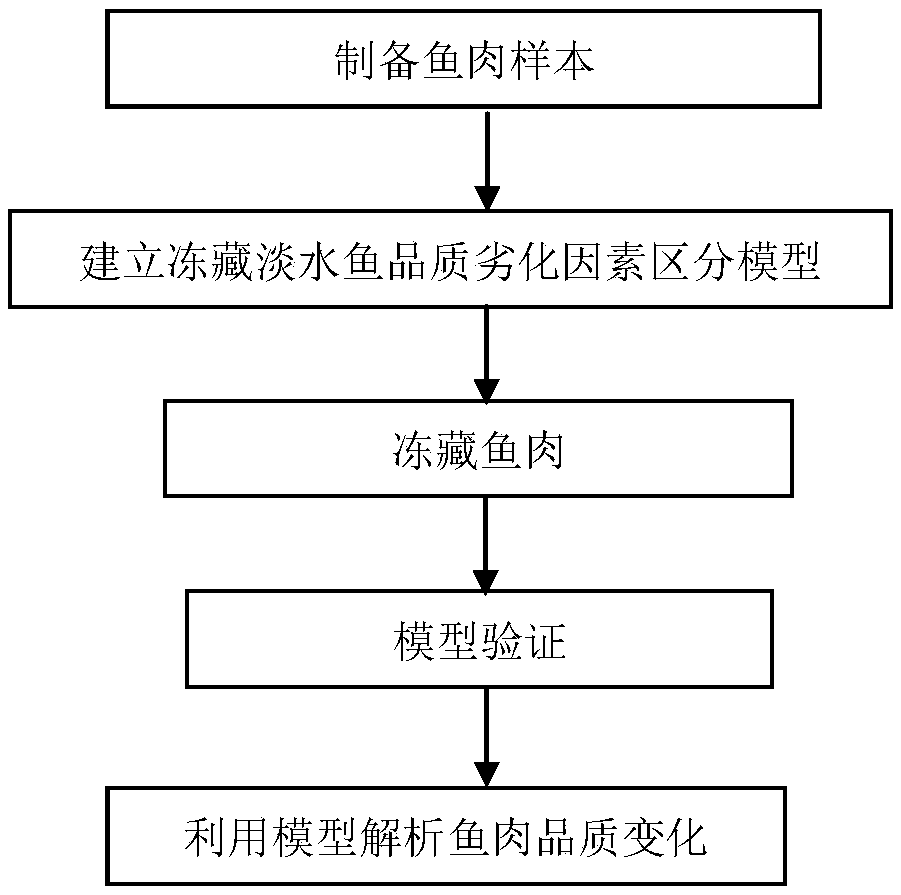

Model analysis method for distinguishing frozen storage fresh water fish meat quality degradation influence factor and application

A technology of influencing factors and freshwater fish, which is applied in the direction of analysis materials, data processing applications, and preparation of test samples, etc., can solve problems such as differences in preservation methods, aggravated fishy smell, and loss of juice, so as to improve preservation effects and avoid waste of resources , the effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

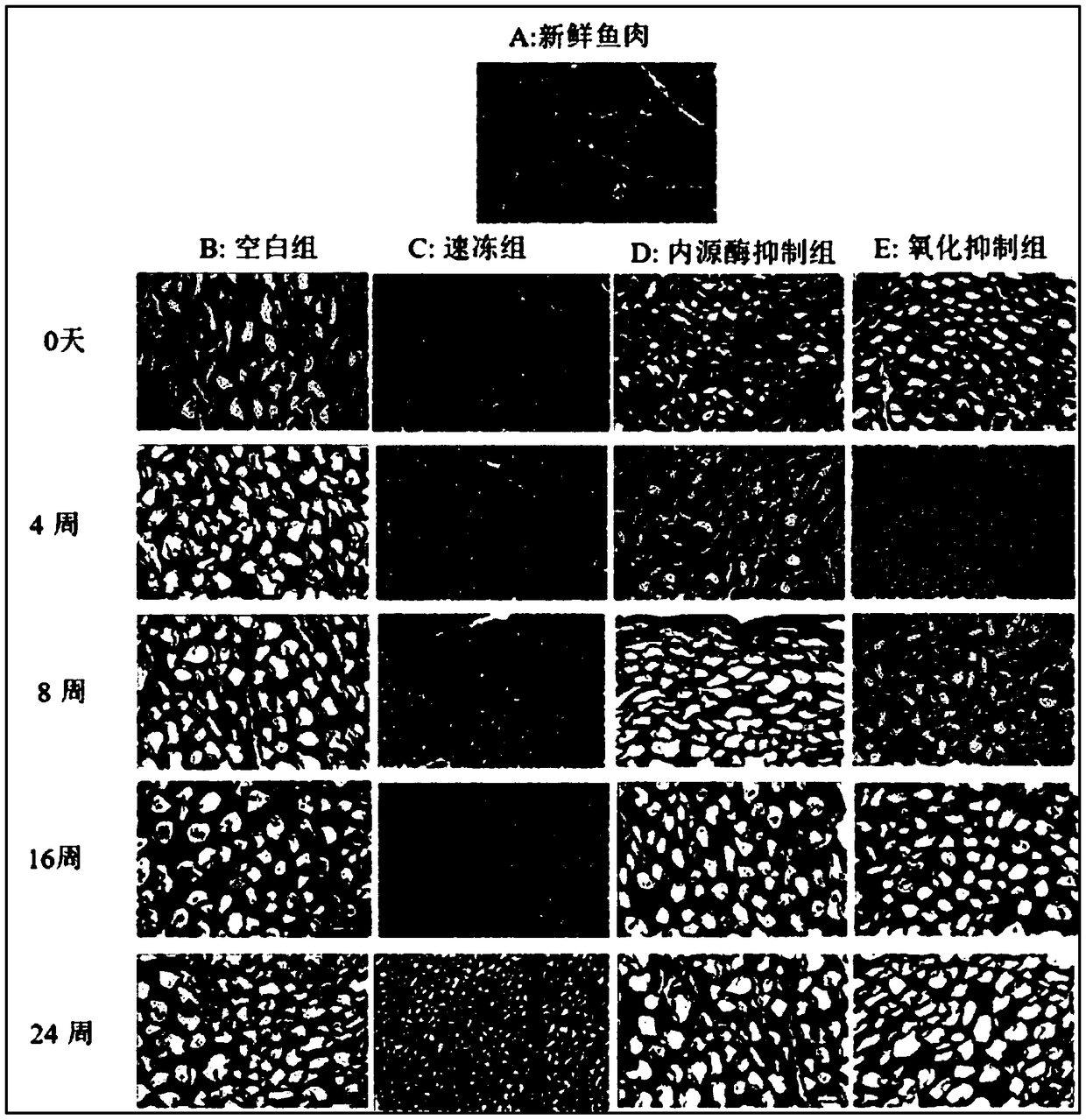

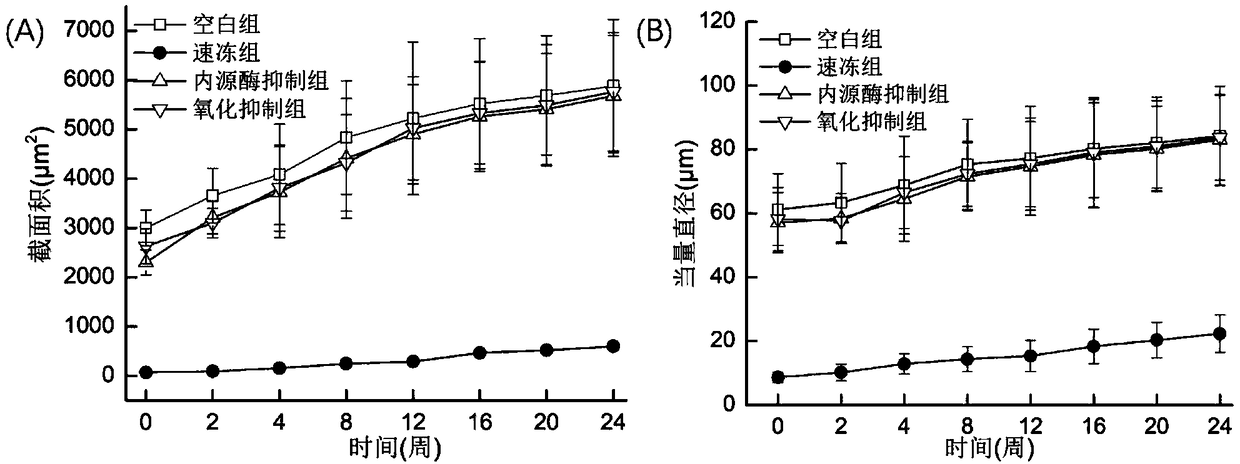

[0052] The model analysis method of the present invention to distinguish the factors affecting the quality deterioration of frozen freshwater fish meat takes grass carp as an example:

[0053] Fifteen grass carp were purchased in Binhu District, Wuxi City in mid-October 2017. The weight of the grass carp was (5±0.5) kg, with healthy physique and neat specifications. Grass carp was slaughtered, head and viscera were removed, rinsed with pre-cooled tap water, the back white muscle was taken, cut into 2cm×2cm×1.5cm blocks, and randomly divided into four groups: A, B, C and D. Group A: Cut fish pieces and soak them in deionized water 1:10 (w / v, g / ml) for 8 hours (6°C), take them out and let them stand for 2 hours (6°C), put them into ziplock bags, and record them as "blank group". "; Group B: Cut the fish pieces and soak them in deionized water 1:10 (w / v, g / ml) for 8 hours (6°C), take them out and let them stand for 2 hours (6°C), immerse and freeze them in liquid nitrogen until t...

Embodiment 2

[0076] 10 Pufferfish obscurus were purchased in Binhu District, Wuxi City in mid-November 2017. The weight of the fish was (1±0.5) kg, the body was healthy, and the specifications were neat. Fugu obscurus was slaughtered, the head and viscera were removed, rinsed with pre-cooled tap water, the white muscle of the back was taken, cut into 2cm×2cm×1.5cm blocks, and randomly divided into four groups: A, B, C and D. Group A: Cut fish pieces and soak them in deionized water 1:8 (w / v, g / ml) for 10 hours (4°C), take them out and let them stand for 2 hours (4°C), put them into ziplock bags, and record them as "blank group". "; B: Cut the fish pieces and soak them in deionized water 1:8 (w / v, g / ml) for 10 hours (4°C), take them out and let them stand for 2 hours (4°C), immerse and freeze them in liquid nitrogen until the center temperature is -10°C ℃, take it out and put it into a ziplock bag, and record it as "quick-frozen group"; group C: soak the cut fish pieces in 1.5mmol / L iodoace...

Embodiment 3

[0078]Fifteen grass carp were purchased in Binhu District, Wuxi City in mid-November 2017. Grass carp weighed (4±0.5) kg, were healthy, and had neat specifications. Grass carp was slaughtered, head and viscera were removed, rinsed with pre-cooled tap water, the back white muscle was taken, cut into 2cm×2cm×1.5cm blocks, and randomly divided into four groups: A, B, C and D. Group A: Cut the fish pieces and soak them in deionized water 1:15 (w / v, g / ml) for 6 hours (10°C), take them out and let them stand for 1 hour (10°C), put them into ziplock bags, and record them as "blank group". "; B: Cut the fish pieces and soak them in deionized water 1:15 (w / v, g / ml) for 6 hours (10°C), take them out and let them stand for 1 hour (10°C), then immerse and freeze them in liquid nitrogen until the center temperature is -25°C ℃, take it out and put it into a ziplock bag, and record it as "quick-frozen group"; group C: soak the cut fish pieces in 2mmol / L iodoacetic acid solution 1:15 (w / v, g / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com