Hollow Fe/N/C fuel cell oxygen reduction catalyst derived from MOFs (Metal Organic Frameworks), and preparation method thereof

A fuel cell and catalyst technology, which is applied in battery electrodes, circuits, electrical components, etc., can solve the problems of large amount of precious metals, low catalyst utilization, low catalytic activity, etc., and achieves simple preparation process, which is conducive to large-scale production, high The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

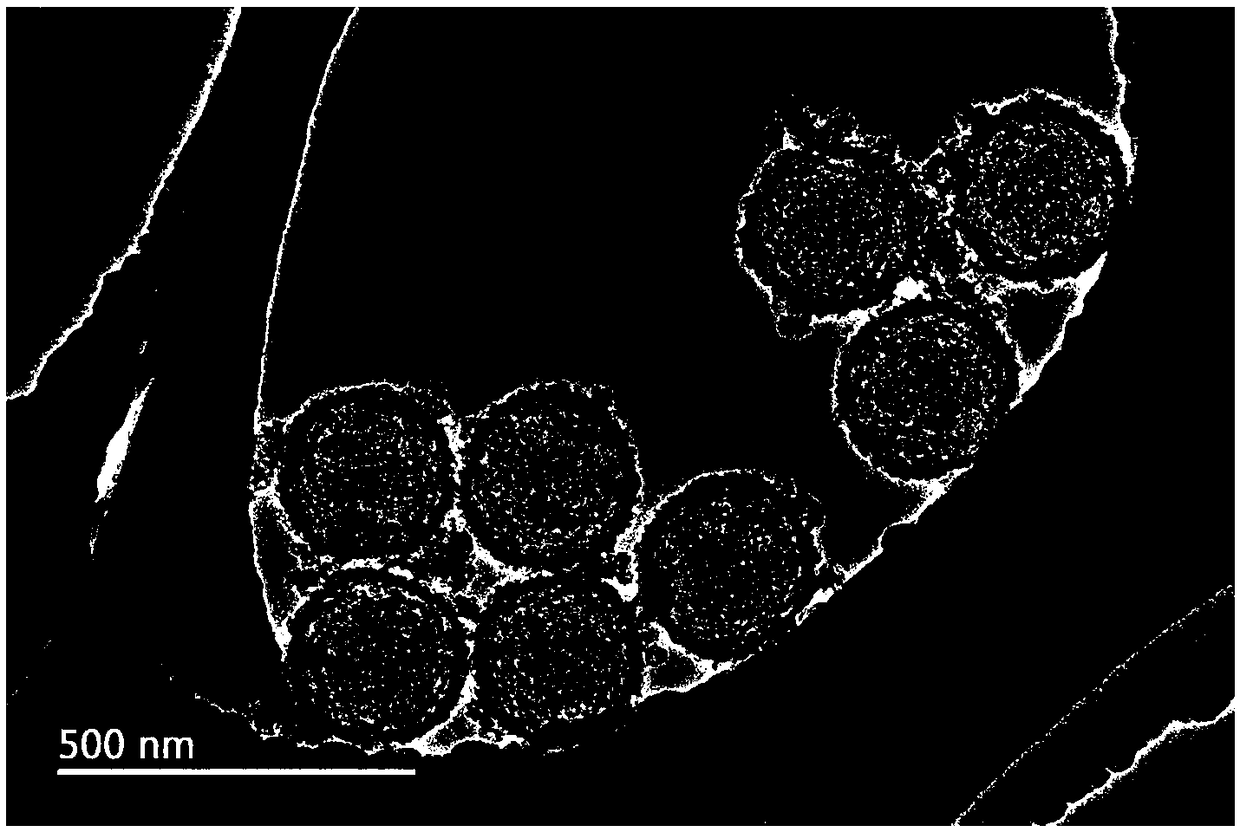

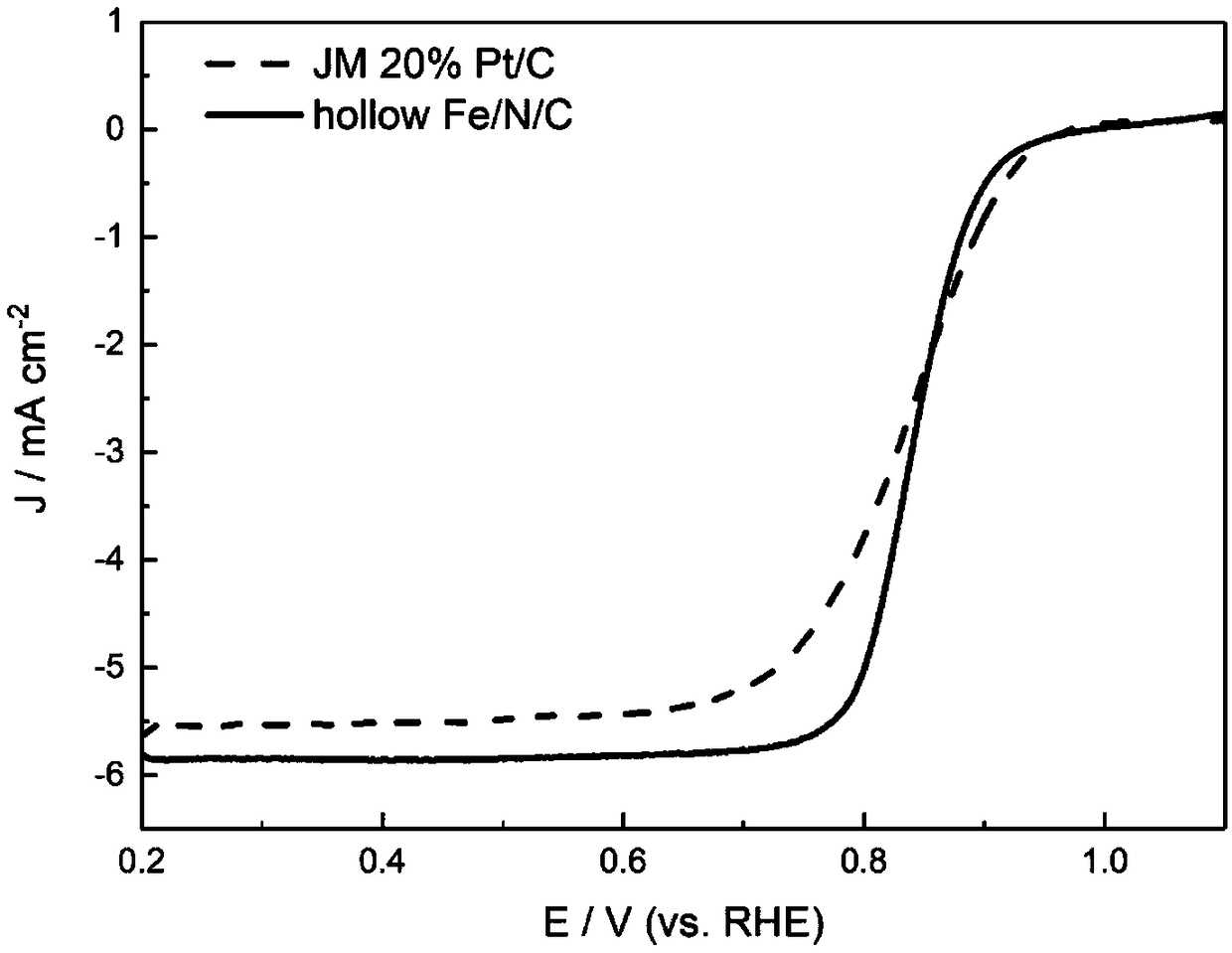

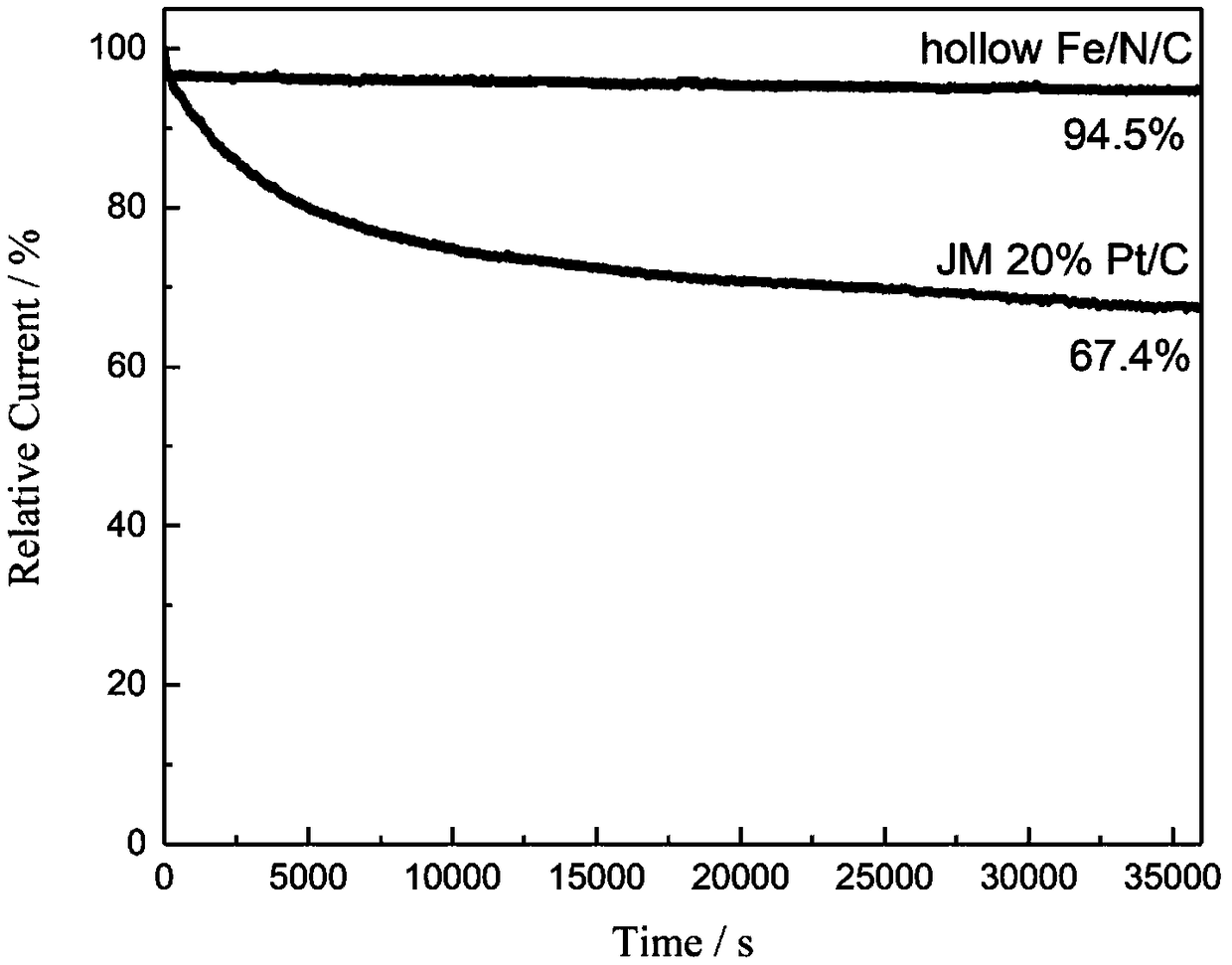

Image

Examples

Embodiment 1

[0033] A method for preparing an oxygen reduction catalyst for a hollow Fe / N / C fuel cell derived from MOFs, the specific steps are as follows:

[0034] (1) Preparation of PS pellet template

[0035] Measure 21ml of styrene, 1.1ml of acrylic acid, 0.92ml of methyl methacrylate, and weigh 0.49g of ammonium bicarbonate and add it, and dissolve the mixture in 100ml of ultrapure water (H 2 (0), heat up to 70°C, add 0.53g ammonium persulfate, heat up to 80°C, stir for 12 hours, after the liquid in the flask is cooled, centrifuge at 8000rpm, then wash several times with a large amount of ultrapure water, freeze-dry for backup use.

[0036] (2) Preparation of Fe / N / C catalyst precursor

[0037]Weigh 594.98mg of zinc nitrate, 20.20mg of ferric nitrate and 691.28mg of 2-methylimidazole, and weigh 200mg of the product in step (1). Zinc nitrate and ferric nitrate were placed in a three-necked round-bottomed flask (referred to as bottle 1), and 2-methylimidazole and PS pellet templates w...

Embodiment 2

[0044] A method for preparing an oxygen reduction catalyst for a hollow Fe / N / C fuel cell derived from MOFs, the specific steps are as follows:

[0045] (1) Preparation of PS pellet template

[0046] Measure 20ml of styrene, 1ml of acrylic acid, 0.9ml of methyl methacrylate, and weigh 0.4g of ammonium bicarbonate and add it, and dissolve the mixture in 100ml of ultrapure water (H 2 (0), heat up to 50°C, add 0.5g ammonium persulfate, heat up to 90°C, stir for 6h, after the liquid in the flask is cooled, centrifuge at 8000rpm, then wash several times with a large amount of ultrapure water, freeze-dry for backup use.

[0047] (2) Preparation of Fe / N / C catalyst precursor

[0048] Weigh 297.49mg of zinc nitrate, 40.40mg of ferric nitrate and 328.4mg of 2-methylimidazole, and weigh 50mg of the product in step (1). Zinc nitrate and ferric nitrate were placed in a three-necked round-bottomed flask (referred to as bottle 1), and 2-methylimidazole and PS pellet templates were placed i...

Embodiment 3

[0052] A method for preparing an oxygen reduction catalyst for a hollow Fe / N / C fuel cell derived from MOFs, the specific steps are as follows:

[0053] (1) Preparation of PS pellet template

[0054] Measure 25ml of styrene, 1.5ml of acrylic acid, 1ml of methyl methacrylate, and weigh 0.5g of ammonium bicarbonate into it, and dissolve the mixture in 100ml of ultrapure water (H 2 (0), heat up to 60°C, add 0.6g of ammonium persulfate, heat up to 100°C, stir for 24 hours, after the liquid in the flask is cooled, centrifuge at 8000rpm, wash with a large amount of ultrapure water several times, freeze-dry for backup use.

[0055] (2) Preparation of Fe / N / C catalyst precursor

[0056] Weigh 297.49mg of zinc nitrate, 101.00mg of ferric nitrate and 1313.6mg of 2-methylimidazole, and weigh 500mg of the product in step (1). Zinc nitrate and ferric nitrate were placed in a three-necked round-bottomed flask (referred to as bottle 1), and 2-methylimidazole and PS pellet templates were pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com