A kind of forging forming method of triple gear, triple gear and application thereof

A triple gear, forging forming technology, applied in the field of gear forging, can solve the problems of large uncontrollable scale removal factors, poor tooth precision, manual grinding, etc., to simplify the manual descaling process, improve the milling efficiency, The effect of improving the pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

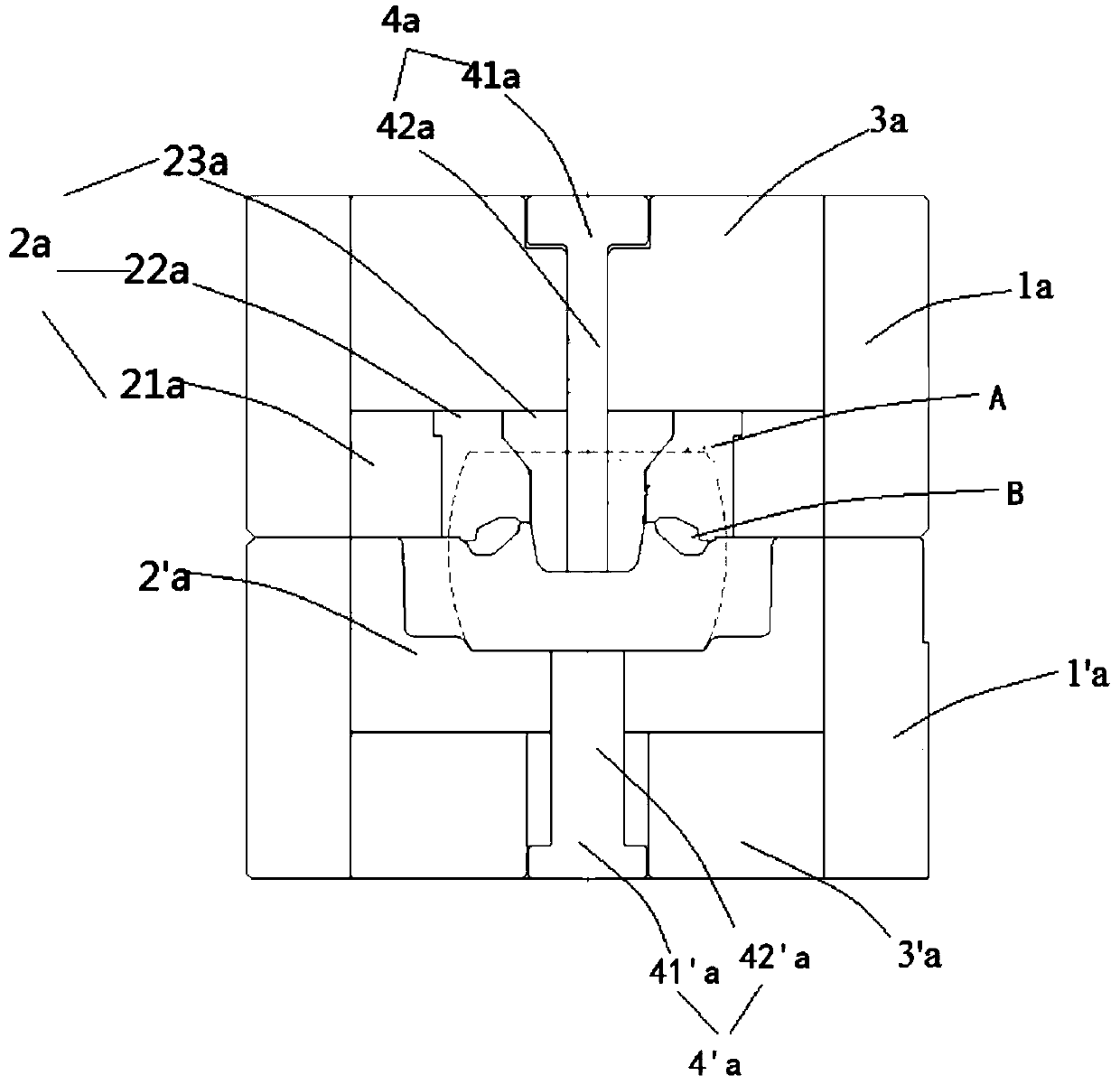

[0046] The forging die used in the forging forming method of the triple gear is a combination die. Such as figure 2 As shown, the pre-forging die includes a rectangular pre-forging upper die sleeve 1a and a pre-forging lower die sleeve 1'a oppositely arranged, and the pre-forging upper die sleeve 1a and the pre-forging lower die sleeve 1'a are interference-fitted. Forging upper die 2a and pre-forging lower die 2'a, pre-forging upper die backing plate 3a and pre-forging lower die backing plate 3'a; respectively with pre-forging upper die backing plate 3a and pre-forging lower die backing plate 3'a Pre-forging upper ejector pin 4a and pre-forging lower ejector pin 4'a with loose fit, wherein, pre-forging upper die 2a includes pre-forging sleeve 1 21a with interference fit, pre-forging bevel tooth die 22a and pre-forging bevel tooth Mold core 23a.

[0047] The center of the pre-forging die is provided with a pre-forging upper ejector pin 4a, and the limit part-41a of the pre-f...

Embodiment 2

[0058] The forging forming method of the triple gear disclosed in this embodiment includes the following steps:

[0059] S1. Pretreatment process: the heated billet is subjected to an upsetting process, the upsetting ratio is 10% to 30%, and the upsetting ratio is selected as 20% in this embodiment; the upsetting surface is removed by high-pressure water skin; the water pressure in the pretreatment process is 10-30MPa, and the water pressure in this embodiment is 15MPa, and the time is less than 0.5S.

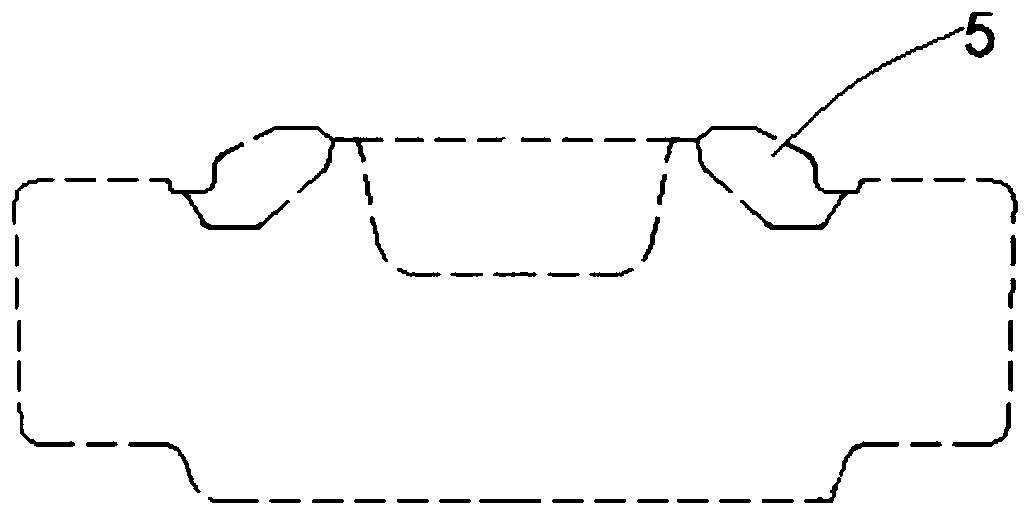

[0060] S2. Forging process: adopt the process of precision forging the top bevel teeth and bottom end teeth of the triple gear at the same time. Teeth are basically formed, such as image 3 , which pre-forges the bevel tooth part 5; the top bevel tooth of the basically formed pre-forging billet faces downward, puts it into the cavity of the final forging die, and is positioned with the basically formed bevel tooth part 5, and the bevel tooth part 5 and the bevel tooth part are...

Embodiment 3

[0066] The forging forming method of the triple gear disclosed in this embodiment includes the following steps:

[0067] S1. Pretreatment process: the heated billet is subjected to an upsetting process, the upsetting ratio is 10% to 30%, and the upsetting ratio is 30% in this embodiment; skin; the water pressure in the pretreatment process is 10-30MPa, and the water pressure in this embodiment is 30MPa, and the time is less than 0.5S.

[0068]S2. Forging process: adopt the process of precise forging of the top bevel teeth and bottom end teeth of the triple gear at the same time, place the upsetting and dephosphorized blank in the pre-forging mold cavity, and perform the pre-forging process to make the triple gear The top bevel teeth are basically formed, and the top bevel teeth of the basically formed pre-forged billet are put into the cavity of the final forging die, and the basic formed bevel teeth are positioned. After forging, a fully formed triple gear with bevel teeth an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com