Steel-concrete combined-assembly-type bridge bent frame pier system and construction method

A combined assembly and concrete technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve problems such as environmental pollution, slow construction speed, limited technology, etc., achieve good shear and torsion resistance, and improve overall seismic performance , Improve the effect of earthquake resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

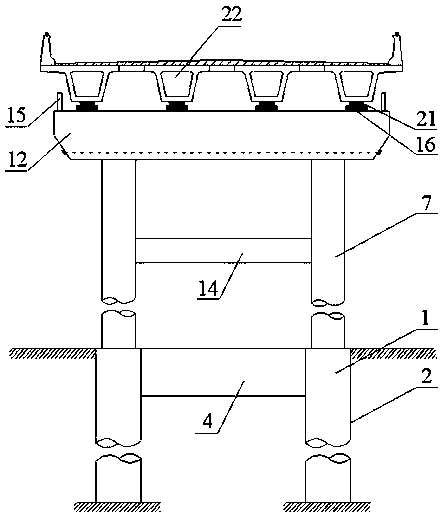

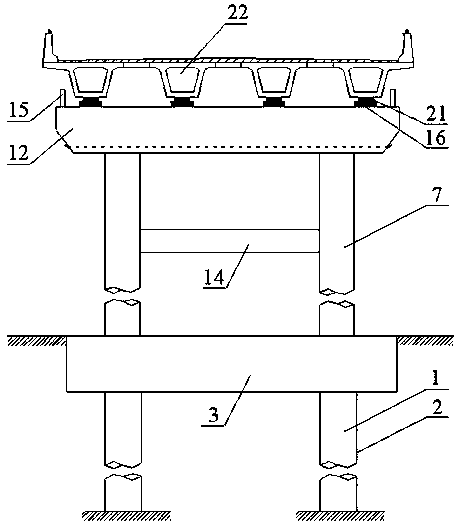

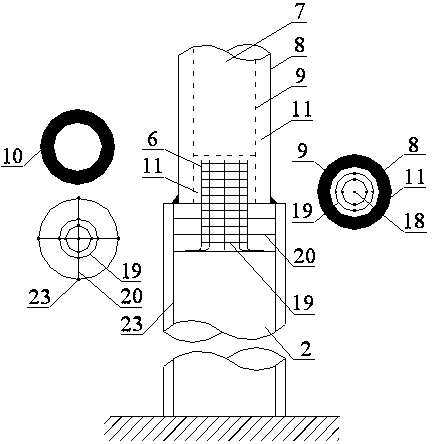

[0017] Such as Figure 1~Figure 8 As shown, the present invention is a steel-concrete composite assembled bridge bent pier system and construction method. The steel-concrete composite assembled bridge bent pier system includes: pile foundation 1, pile column 2, cap 3, ground tie beam 4. Annular steel plate 5, reserved reinforcement cage 6, hollow steel tube concrete double-column pier 7, outer steel tube 8, inner steel tube 9, ring steel plate 10, plain concrete 11, steel cover beam 12, prestressed steel bar 13, I-beam cross Tie beam 14, steel plate block 15, steel plate pad stone 16, high-strength bolt buckle 17, support 21, main beam 22, pile foundation 1 is divided into two situations on the basis of pile column 2: one is with cap 3 without Ground tie beam 4, one is with ground tie beam 4 without cap 3; pile foundation 1, pile column 2, cap 3, and ground tie beam 4 are all cast-in-place in the form of integral cast-in-place; The top of the platform 3 is equipped with the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com