A four-quadrant operating hydraulic motor pump

A hydraulic motor and four-quadrant technology, applied to pumps, pump components, mechanical equipment, etc., can solve the problems of inability to switch between forward and reverse working conditions, reduce the total efficiency of hydraulic motor pumps, and increase air gap viscous loss, etc., to achieve Good braking effect, compact structure, and the effect of avoiding viscous loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

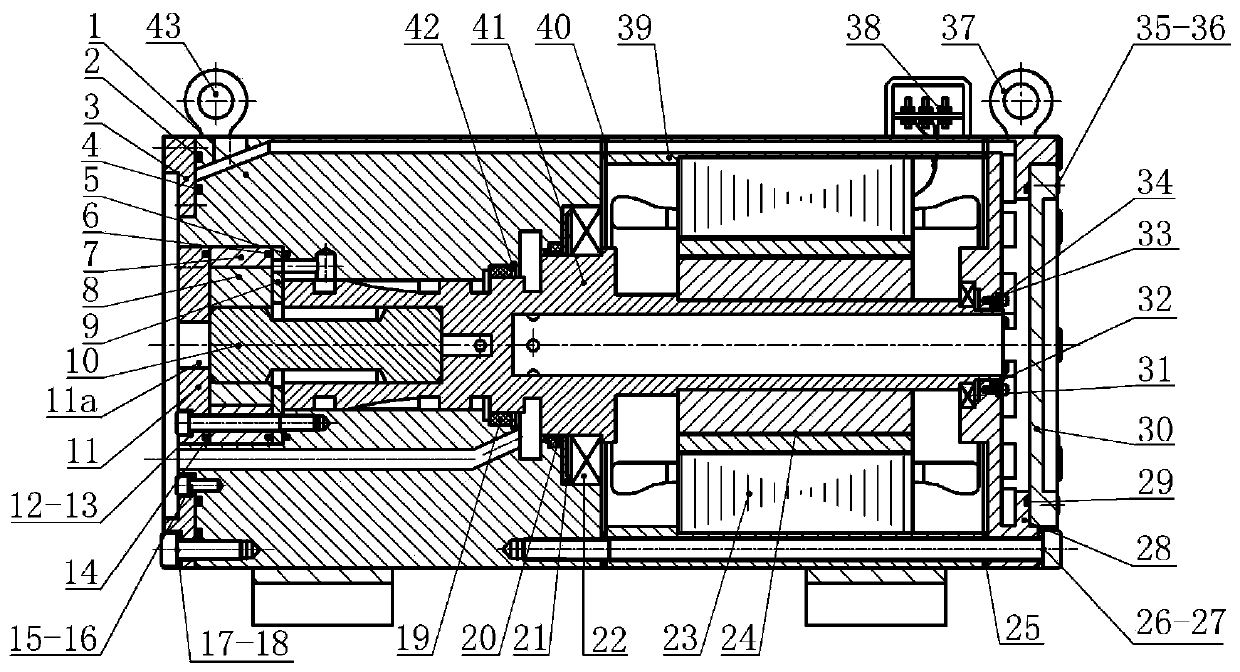

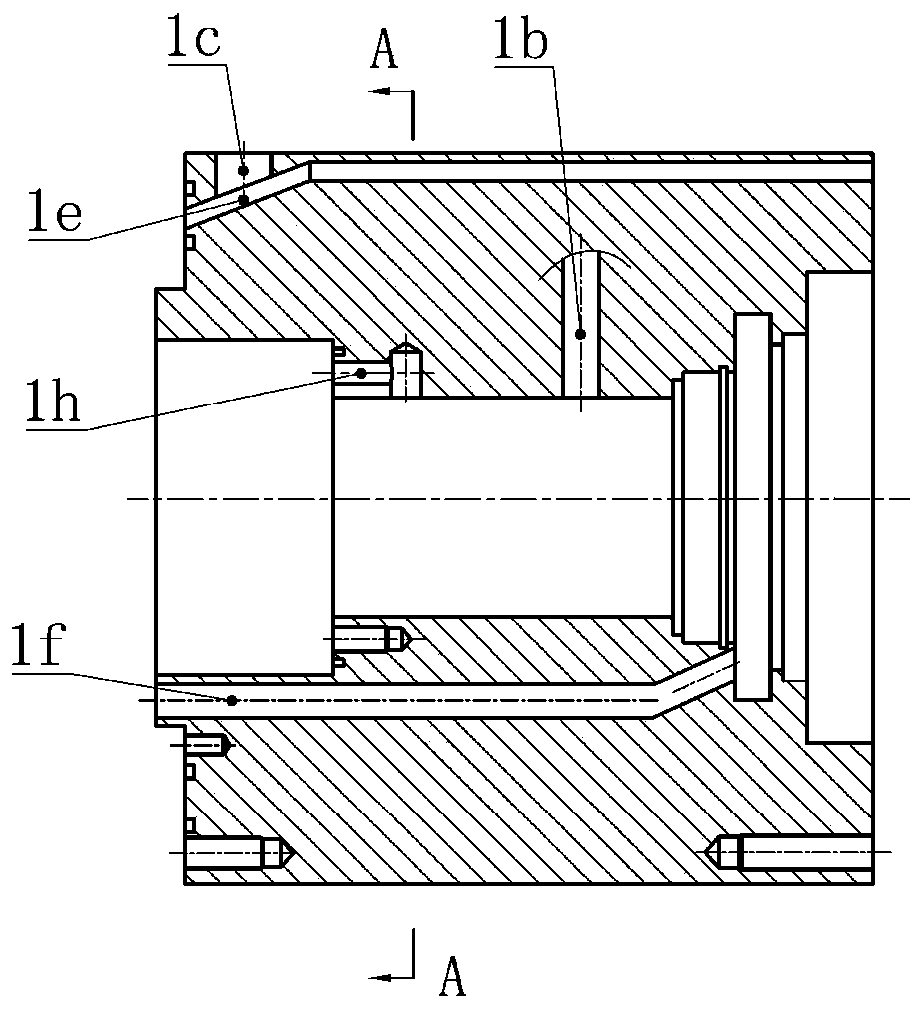

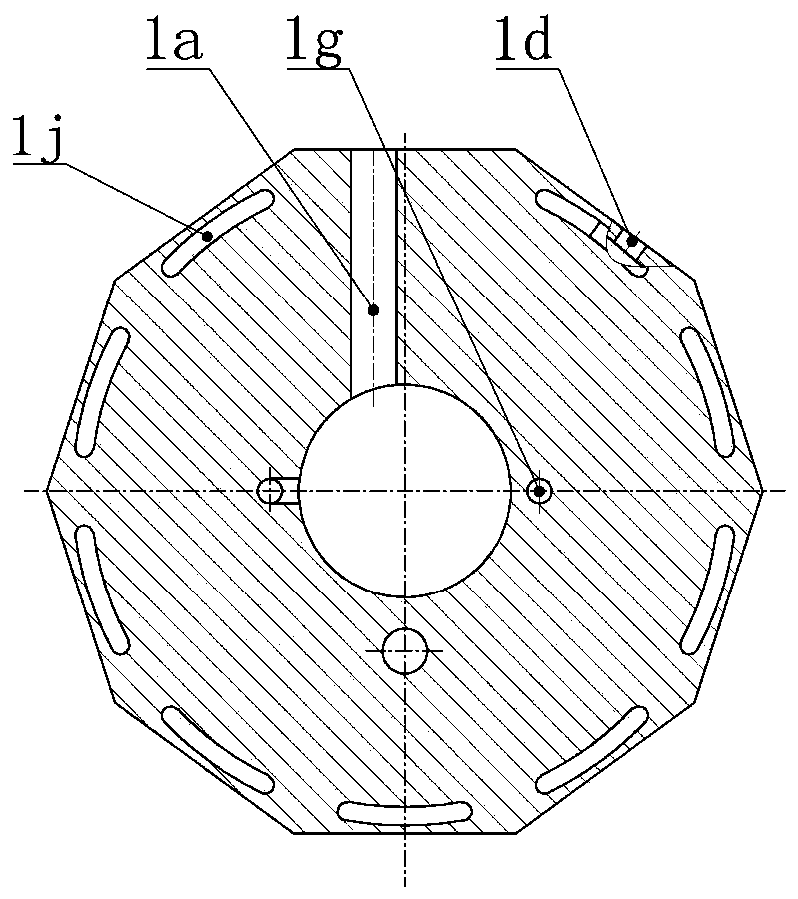

[0022] Such as Figures 1 to 6 As shown, the described four-quadrant operation hydraulic motor pump is characterized in that it includes a main shaft 41, on which a motor rotor 24 is mounted, and the main shaft 41 is supported and installed on the front casing by the first bearing 22 and the second bearing 31. 1 and the rear end cover 30, the motor rotor 8 is connected to the main shaft 41 through the drum spline coupling 10, and the motor rotor 8 passes through the spacer 9, the motor stator 7, the motor end cover 11, the third sealing ring 14, the second The sealing ring 6, the first sealing ring 5, the third screw 12 and the third washer 13 are fixed in the front housing 1, the motor stator 23 is press-fitted on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com