Grain matched drying device for agricultural production

A drying device and grain technology, applied in drying, drying machine, heating device and other directions, can solve the problems of poor grain heating uniformity, low heat utilization efficiency, single drying form, etc. Large drying contact area, reducing loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

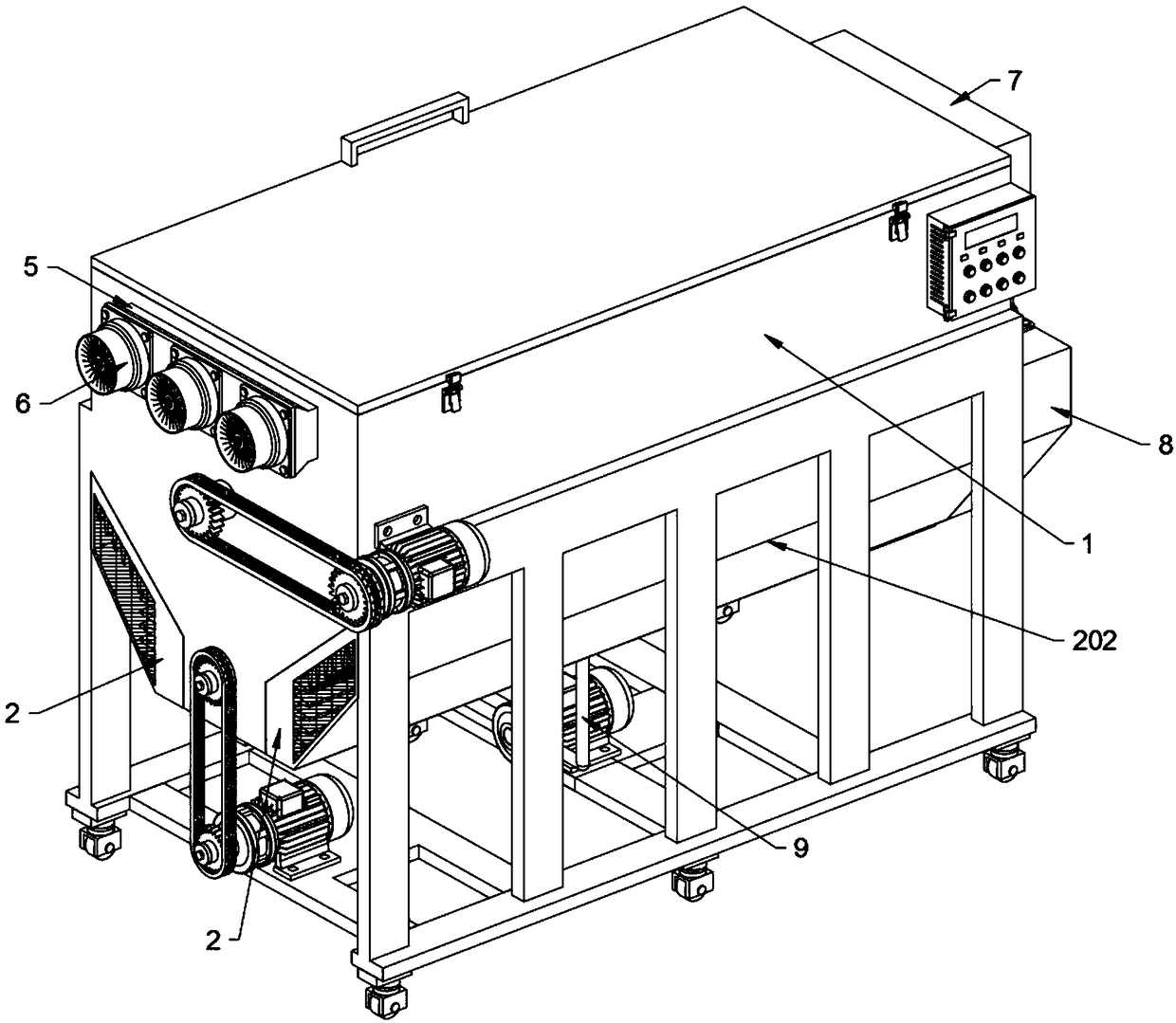

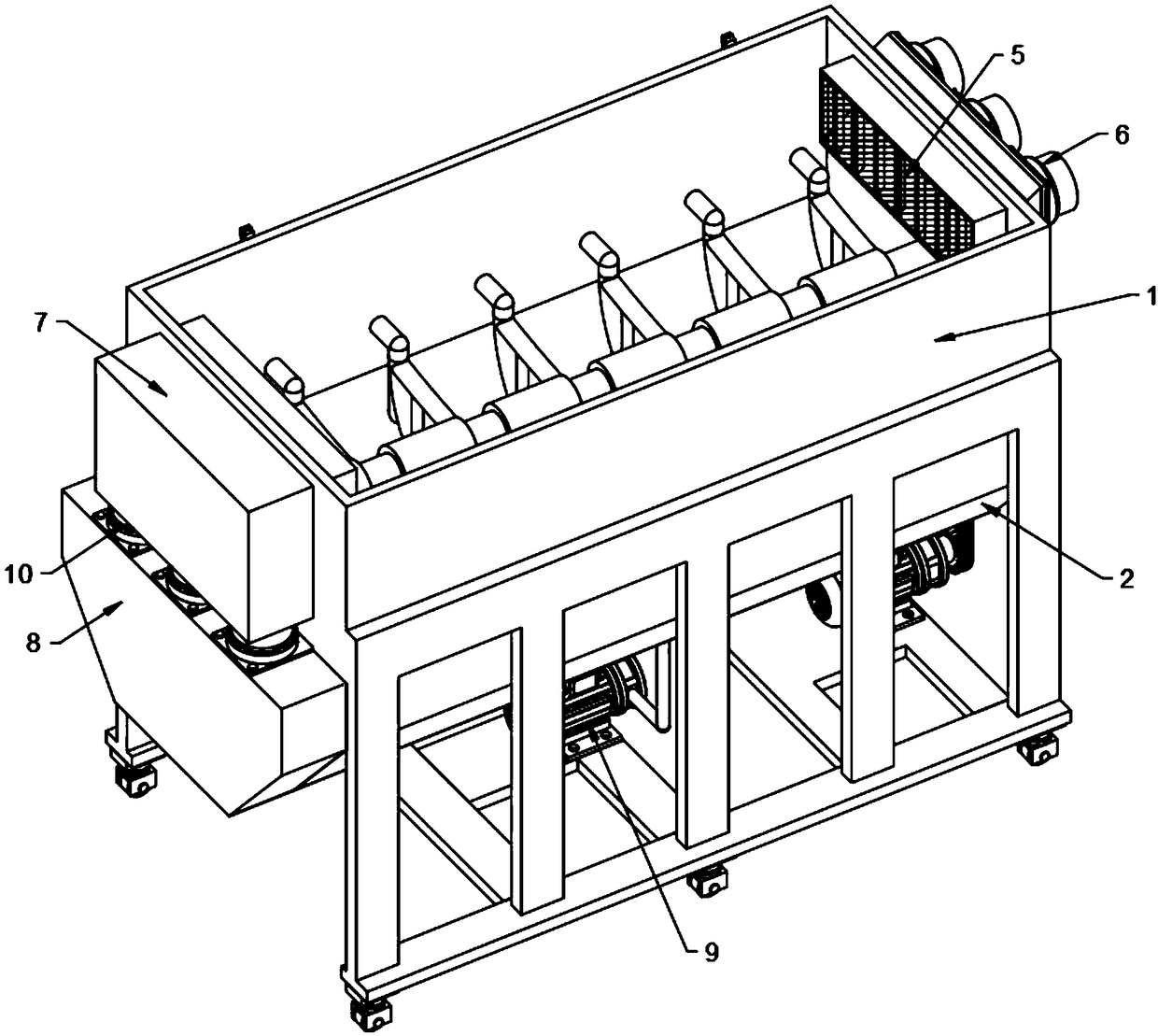

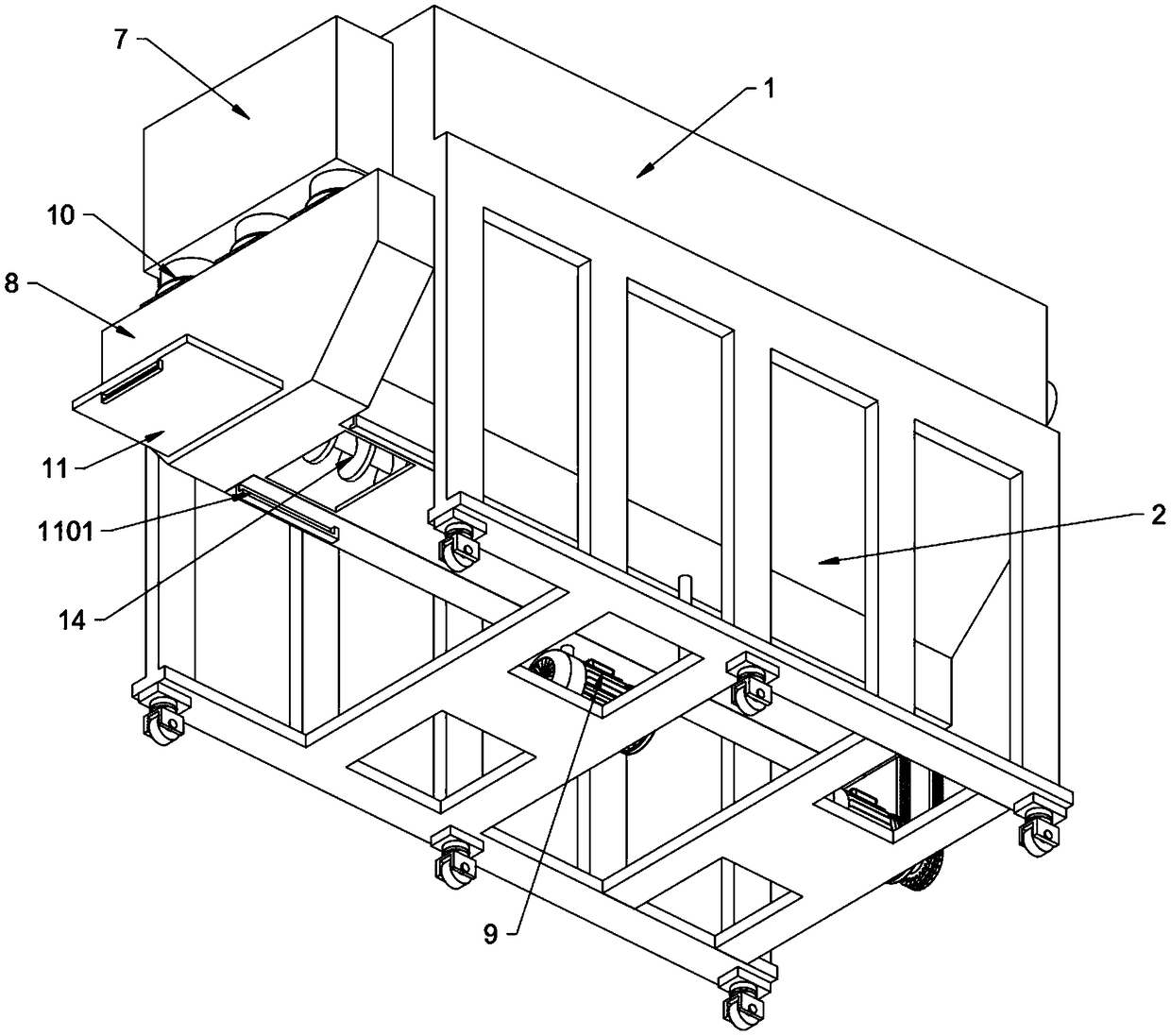

[0036] as attached figure 1 to attach Figure 10 Shown:

[0037]The present invention provides a grain drying device for agricultural production, which includes a drying box 1, a heating oil tank 2, a heat dissipation grid 201, an oil tank cover 202, a stirring shaft 3, a grain rack 4, an air outlet tube 5, a Suction fan 6, air inlet cylinder 7, air suction cover 8, oil pump 9, air inlet fan 10, discharge opening cover plate 11, cover plate slot 1101, heating pipe frame 12, pipe frame inlet and outlet oil pipe 1201, grain grilling groove 13 and Jiaolong 14; the drying box 1 is arranged as a cuboid as a whole, and the top opening is provided with a rotating cover, and the outer walls of the left and right sides are equally spaced and supported with four supporting legs; the heating pipe frame 12 is provided with There are seven, and the seven heating pipe racks 12 are equidistantly arranged and supported inside the drying box 1; the peripheral semi-circular oil pipes of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com