Sensor monocrystalline silicon etching device capable of etching uniformly

An etching device and technology of single crystal silicon, applied in the field of sensors, can solve the problems of low etching efficiency and poor etching effect, and achieve the effect of sufficient etching and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

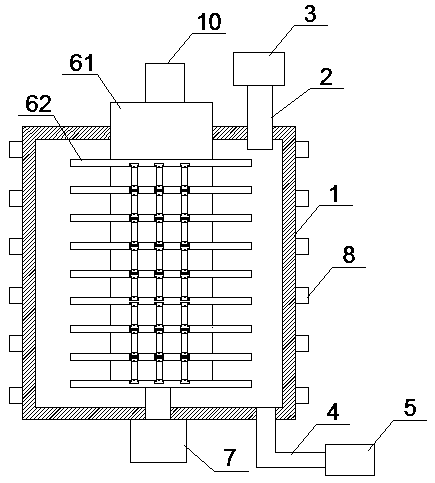

[0020] like Figure 1-3 As shown, the present invention discloses a single crystal silicon etching device for sensors with uniform etching, which includes a reaction chamber 1, and an air supply pipe 2 is arranged on the upper end of the reaction chamber 1, which is connected to a gas supply pipe 2 arranged outside the reaction chamber 1. The source chamber 3 and the lower end of the reaction chamber 3 are provided with a pumping pipe 4, which is connected to a vacuum pump 5 arranged outside the reaction chamber; the axial position of the reaction chamber 1 is provided with a sheet rack 6, which is connected to the vacuum pump 5 arranged outside the reaction chamber. 1. The output shaft of the external servo motor 7; an electromagnetic coil 8 is arranged on the outside of the reaction chamber 1;

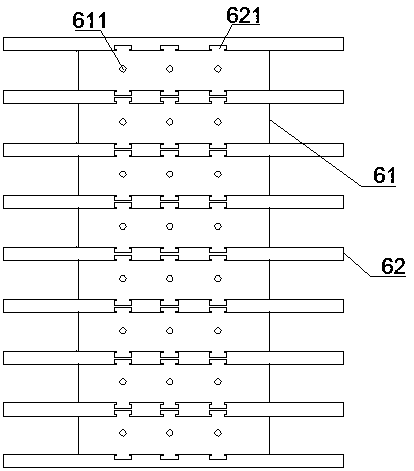

[0021] The sheet holder 6 is composed of a hollow cylindrical rotating column 61 and an annular plate 62 uniformly fixedly connected to the outer wall of the rotating column, and the...

Embodiment 2

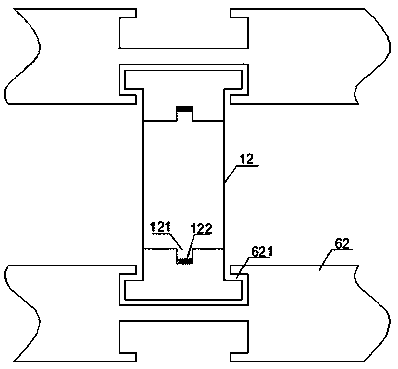

[0029] As a further improvement: According to [ image 3 ], the inner wall of the card slot 121 is provided with an elastic rubber pad 122 . The improved advantage of this embodiment: it is used to prevent the monocrystalline silicon wafer from being damaged by the clamping plate 12 .

[0030] The remaining features and advantages of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0032] As a further improvement: the width of the end of the horizontal bar on the clamping plate 12 away from the U-shaped plate on the clamping plate 12 is greater than the diameter of the sliding hole 611 . The improved advantage of this embodiment: preventing the clamping rod 12 from detaching from the sliding hole 611 .

[0033] The remaining features and advantages of this embodiment are the same as those of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com