Preparation method of NBR latex anti-slip gloves

A technology of nitrile rubber and gloves, applied in gloves, protective clothing, clothing and other directions, can solve the problems of poor wearing feeling and high production cost of gloves, and achieve the effects of comfortable wearing, high softness and good touch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

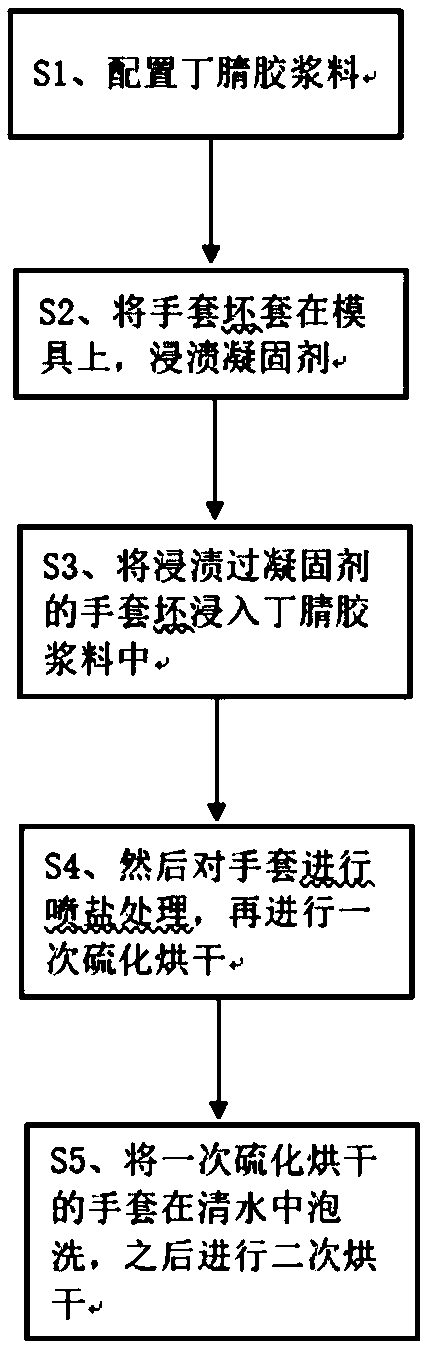

[0031] The specific embodiment part of the present invention provides a kind of preparation method of nitrile latex non-slip gloves, comprises the following steps:

[0032] S1. Configure nitrile rubber slurry: put 1000-1500 parts by weight of nitrile rubber into the stirring device, stir at a speed of 30-40r / min, add 100-130 parts by weight of plasticizer, 20-30 parts by weight of plasticizer Thickener, 4-5 parts by weight of emulsifier, 6-7 parts by weight of ball mill, 10-15 parts by weight of diffusing agent, 90-120 parts by weight of water, continue to stir for 2-3 hours, then stand at 20-25 ° C for 12- 15h.

[0033] Specifically, the plasticizer can be selected from one or more of DOTP, ATBC, DINCH and DOA; Several; the thickener can be selected from one or more of sodium polyacrylate, casein or sodium hydroxymethyl cellulose; the diffusing agent can be selected from sodium methylene dinaphthalene sulfonate or dibutyl naphthalene sulfonic acid One or more of sodium. Th...

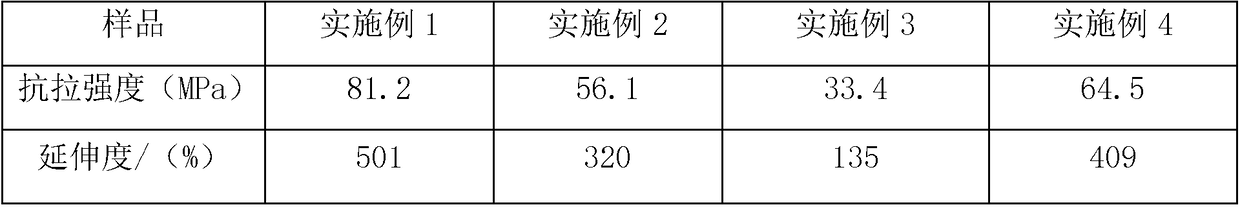

Embodiment 1

[0049] The embodiment of the present invention discloses a kind of preparation method of nitrile latex non-slip gloves, comprising the following steps:

[0050] (1) Configure nitrile rubber slurry: put 1000 parts by weight of nitrile rubber into the stirring device, stir at a speed of 30r / min, add 100 parts by weight of plasticizer, 20 parts by weight of thickener, and 4 parts by weight of emulsifying Agent, 6 parts by weight of ball mill, 10 parts by weight of diffusing agent, 90 parts by weight of water, after continuing to stir for 2 hours, let it stand at 20°C for 12 hours; choose DOTP as plasticizer, sodium polyacrylate as thickener, and sodium polyacrylate as diffusing agent Sodium methylene dinaphthalene sulfonate, the ball mill comprises the following components: 15 parts by weight of sulfur, 25 parts by weight of zinc oxide, 25 parts by weight of titanium dioxide, 2 parts by weight of accelerator, 15 parts by weight of antioxidant, and 2 parts by weight of dispersant ...

Embodiment 2

[0056] The embodiment of the present invention discloses a preparation method of nitrile latex non-slip gloves, comprising the following steps: (1) configuring nitrile rubber slurry: putting 1000 parts by weight of nitrile rubber into a stirring device and stirring at a speed of 30r / min , add 80 parts by weight of plasticizer, 20 parts by weight of thickener, 4 parts by weight of emulsifier, 6 parts by weight of ball mill, 10 parts by weight of diffusing agent, 90 parts by weight of water, and continue to stir for 2 hours. Stand still for 12 hours; use DOTP as the plasticizer, sodium polyacrylate as the thickener, sodium methylene dinaphthalene sulfonate as the diffusing agent, and the ball abrasive includes the following components: 15 parts by weight of sulfur, 25 parts by weight of zinc oxide, titanium dioxide 25 parts by weight, 2 parts by weight of accelerator, 15 parts by weight of anti-aging agent, 2 parts by weight of dispersant, 8 parts by weight of thickener, and 100 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com